Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Technology has shaped significant sectors over the past years, including the packaging industry. Multihead weighers are widely used in all businesses, and the results are generated through a very controlled and precise microcomputer-generated method. Multihead weighers are also referred to as combination weighers because their task is to take out the best possible combination of weight for a product.

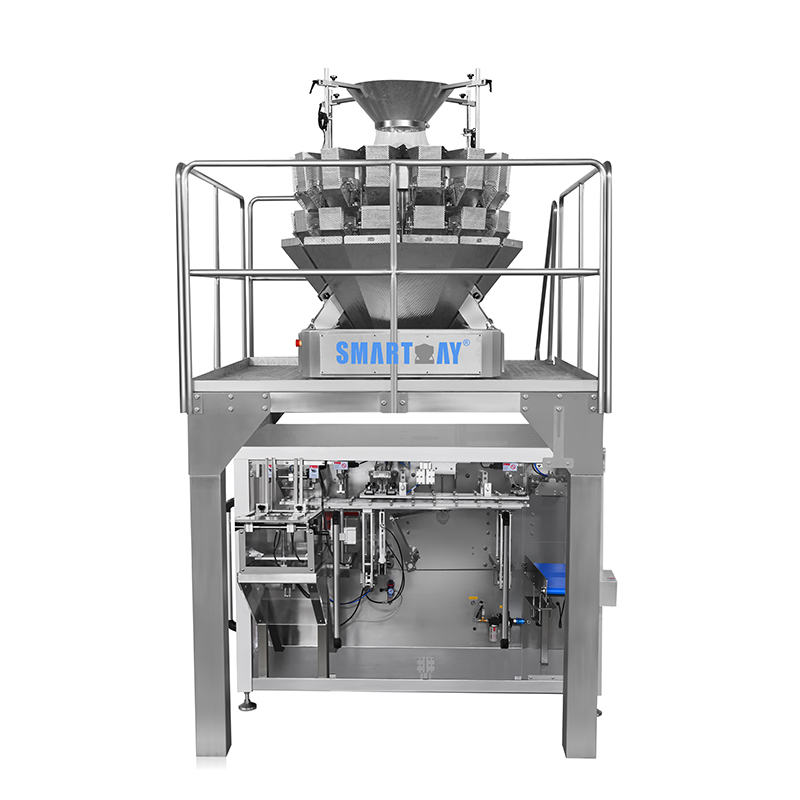

A multihead weigher is a machine used in the packaging industry to weigh and dispense products such as food, pharmaceuticals, and chemicals. It consists of multiple weighing heads (usually between 10 and 16), each containing a load cell, which is used to measure the weight of the product.

To calculate combinations, a multihead weigher uses a computer program that is programmed with the target weight for the product to be dispensed and the weight of each individual product. The program uses this information to determine the optimal combination of products to achieve the target weight.

The program also takes into account various factors such as product density, flow characteristics, and the desired speed of the machine. This information is used to optimize the weighing process and ensure accurate and efficient dispensing of the product.

The multihead weigher uses a process called "combination weighing" to determine the optimal combination of products to dispense. This involves weighing a small sample of the product and using statistical algorithms to determine the most efficient combination of products that will achieve the target weight.

Once the optimal combination has been determined, the multihead weigher dispenses the products into a bag or container, ready for packaging. The entire process is highly automated and can be completed in a matter of seconds, making multihead weighers a popular choice for high-volume packaging operations.

The main action takes place when the product is evenly distributed. The primary function of the linear feeder is to deliver products to the feed hopper where the action takes place. For example, in a 20-head multi-weigher, there have to be 20 linear feeders delivering products to 20 feed hoppers. These contents are eventually emptied in to the weigh hopper, which has a load cell. Each weigh head has its precision weigh cell. This load cell helps calculate the product's weight in the weigh hopper. The multihead weigher is equipped with a processor that finally calculates the best possible combination of all the available weights required to achieve the desired target weight.

It is a known fact that the more weigh heads present on your multihead weighing machine result in a faster combination generation. The accurately weighed portions of any product can be produced in the same period. The general single-head scale is on its way to achieving the desired weight. The feeding rate cannot be too quick to assure precision. In most cases, the amount of material in each hopper is set at 1/3 to 1/5 of the goal weight.

During the calculation of the combination weigher, only partial combinations are employed. The number of heads participating in a combination can be estimated using the formula: n=Cim=m! / I! (m - I)! Where m is the total number of weighing hoppers in the combination, and I stands for the number of buckets involved. Typically, as m, I, and the number of possible combinations grow, obtaining a good product increases.

Your multihead weigher can be customized with various optional additions to ensure that it performs well with a variety of products. A timing hopper is the most typical of these functions. A timing hopper collects the product discharged from the weigh hoppers and holds it until the packaging machinery directs/signals it to open. Until the timing hopper has opened and closed, the multi-head weigher will not discharge any product from the weigh hoppers. It speeds up the process by shortening the distance between the multi-head weigher and the packing equipment. One added benefit is booster hoppers, also known as an extra layer of hoppers added to store the product which has already been weighed in the weight hopper. This product is not being used in a weighment, increasing the suitable combinations available to the system and further increasing speed and accuracy.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved