Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

A packaging machine is a very important tool in an industrial production line. It can be used to pack products, such as toys or other goods that need to be sealed for shipping.

Many people are interested in buying this type of machine because they want to know more about it before making their decision. To help you understand what makes a packaging machine good or bad and how much they cost, we have put together this guide:

Various Packaging Machines

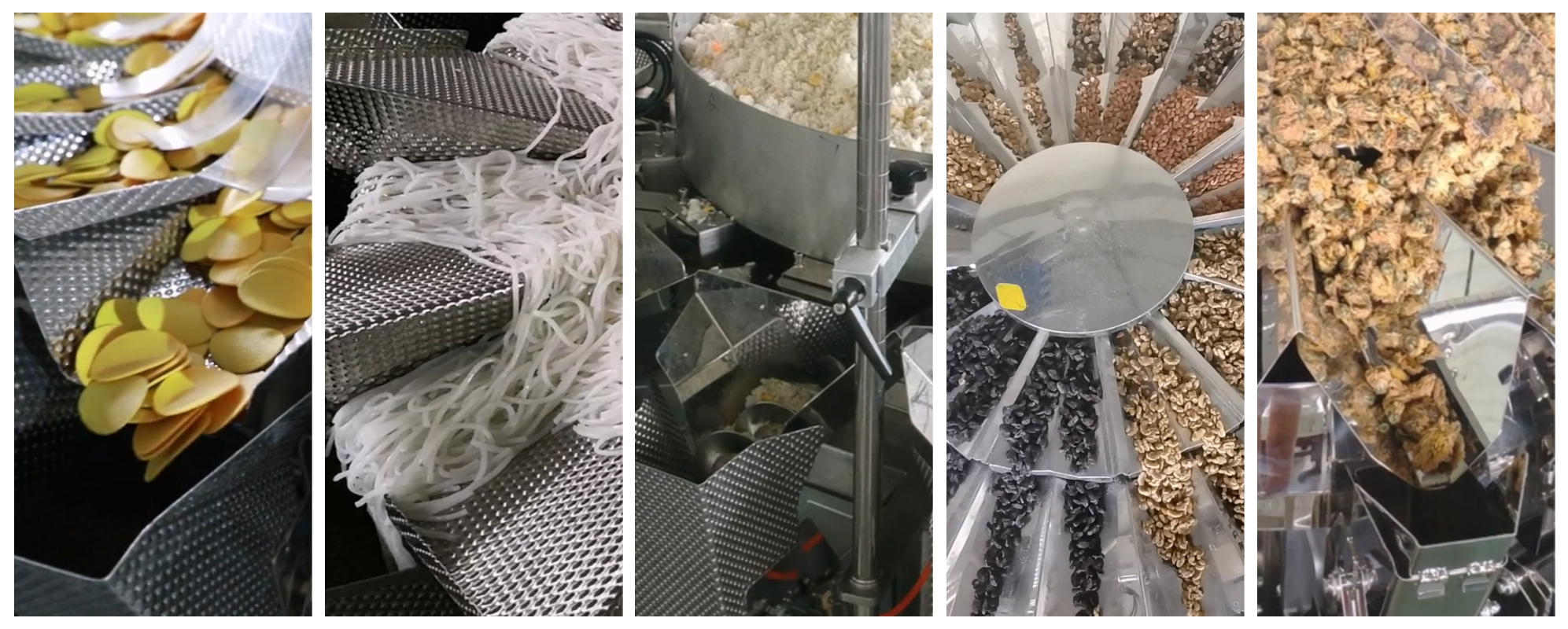

There are many types of packaging machines. The packaging machine is suitable for a variety of different products and materials, so it can be used in many industries. The size, speed, and packaging requirements of the packaging machine directly affect the purchase budget.

How to Choose a Better Packing Machine?

The size, speed, containers, and packaging requirements of the packaging machine directly affect the purchase budget.

The size and speed of the packaging machine are determined by the size of the product and its packaging requirements. If you need to pack small products like chips, candy, jerky, in small quantities with high efficiency, then you should choose an advanced model with high-speed multihead weigher and vertical form fill seal machine; if your business needs more volume or large package of weight then choose a lower-speed model which can help save costs on electricity consumption because it does not require as much power compared with high-speed models.

Flexible packaging solution designs allow users to adjust machines according to their needs: from simple single-station premade bag packing machine, vertical packing machine to tray packing machine, we also offer additional functionality such as automatic cartonong and palletizing for the producution line.

The Size, Speed, and Packaging Requirements

If you are looking for a small-sized machine that can only handle light-duty applications and does not require high-speed robotics or automation features, then you may want to consider purchasing a smaller unit. It has the qualities of a multi-head weigher packaging machine.

The speed at which your packaging line will operate will determine how much money should be spent on its purchase price. Machines that process materials quickly tend to be more expensive than those which require longer processing times (i.e., manual labor). In general terms though:

● If there are many different packages being packed at once—such as cases being filled one after another—then buy a faster machine so there's less downtime between each package passing through; this could save thousands of overtime on labor costs alone!

● If there are only two items per second passing through—for example when boxing up individual items like pens/toys.

Packaging Machine Suitable for Products

Packaging machines are used for a variety of different products and materials. The packaging machine can be used to pack food, beverages, and other consumables in containers such as pillow bags, gusset bags, premade bags, aluminum cans, glass bottles, PET plastic bottles, trays and etc.

A VFFS machine is a machine that forms film into a tube shape by constantly feeding it from a film roll to construct a bag (like a pillow shape). After this, the machine feeds the film tube in a vertical direction while concurrently filling the product.

Packaging machines are available in many different sizes depending on the size of your products to be packaged - from small tabletop models that only require one operator at a time to large production lines with multiple stations which require more than one operator per station working together as a team effort toward achieving high levels of efficiency & productivity within their respective areas/areas of operation; these differences make choosing one type over another based solely on price alone difficult at best (and often impossible).

Central Control System

Central control systems are more convenient than the earlier systems. With a central control system, you can use one device to control multiple packing machines at once. It’s easy to switch between different settings on your machine with this type of setup because there is only one unit in charge of all its functions. For example, if you want to change settings for each individual product being packed then this is possible with a central control system since it has built-in software that allows users to access all their settings from one interface screen.

In addition, many people prefer using central controls because they don't have to go through lengthy procedures when switching between different types of packaging machines (such as hand assembly versus automatic). They simply plug their device into an outlet and start working right away without having any issues whatsoever!

Photoelectric Sensor

The photoelectric sensor is used to detect the position of the packaging material. This unit is installed on a packaging machine and can be used to detect eyemark, ensure the cutter of packing machine produce and cut the bags in the right position.

Weighing Machine System

The weighing machine system is a kind of weighing system for packaging machines. It can weigh the products before packaging.

The main function of the multihead weigher is to weigh and fill the products as preset weight, it has good connection of packaging machine so the complete weighing packing line runs smoothly and effiency.

Automated Packing Machines

Packaging machines can meet the different needs of customers. They can be used for different products and materials, such as food products, pharmaceutical drugs, and chemicals. The size, speed, and packaging requirements of the packaging machine directly affect the purchase budget.

Packaging machines are used in many industries such as the food packaging industry (chicken meat), cosmetic packaging industry (cosmetics), healthcare industry (medicine), electronic goods distribution centers, etc.

Conclusion

In summary, the packaging machine is a very important part of the production line. It can be used in various fields and industries such as food, medicine, or the chemical industry. The size and speed of the packaging machine directly affect its cost, which must be taken into consideration when choosing a good one. The design and function of the packing machine should also meet your specific needs. Finally, when buying a packaging machine it is recommended that you choose one with a central control system instead.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved