Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

As more and more rice noodle projects we are completed, many rice noodle manufacturers have approached us and want us to provide automatic rice noodle weighing and packaging solutions.

As a matter of fact, instant rice noodles are the newly fast food, have emerged as a popular alternative to traditional instant noodles. Recognizing this trend, Smart Weigh has introduced a groundbreaking solution to the rice noodle industry: the Rice Noodle Automatic Feeding, Weighing, Bowl Filling, Shaping, and Drying System. This blog post delves into the transformative impact of this system on the rice noodle packaging machine process.

Then let's see one of our recent noodles packaging machine cases.

Our customer already had machine for packaging rice noodles, the functions are shaping and drying noodles. Now the weighing work is done by hand, 22 workers are needed for this task. This process was not only inefficient but also raised concerns regarding hygiene and consistency. Worker fatigue often led to inaccuracies in weight measurements, compromising product quality.

Known from our other customers, Smart Weigh has the good solution for automatic weighing machine for rice noodles.

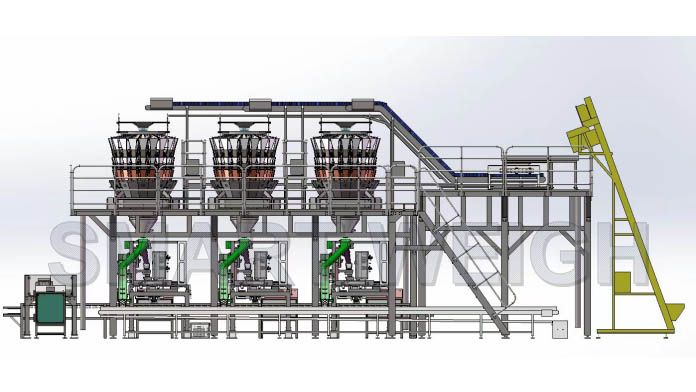

Besides the weighing machine - rice noodles multihead weigher, we also offer infeed conveyor for auto feeding. And design the filling machine which is perfect intergrated customer's exsiting shaping and drying machine.

The drying machine handle 12 portions rice noodles per cycle, our solution is using 3 sets noodles multihead weigher with 1 to 4 filling machine. Each set of weighing filling machine staggered placed, weighed and filled 4 portions at a time.

The system boasts an impressive efficiency of 210 parts per minute, with a daily production capacity of 270,000 parts over two shifts in 22 hours. This remarkable speed significantly enhances production rates, catering to the high demand for rice noodles in the market.

One of the most significant advantages of this system is its ability to drastically reduce labor requirements. From needing 22 people, the process now requires only three workers to add ingredients, saving significant labor costs and resources.

Accuracy is crucial in food packaging. The Smart Weigh system ensures a precision control of +/-3.0g of wet rice flour. Additionally, it has the capability to automatically redirect unqualified products back to the elevator for re-feeding and weighing, ensuring consistent product quality.

The rice noodle packaging machine system includes a specially designed distributing mechanism that perfectly positions the rice noodles into 12 bowls per row in the dryer. It also pre-shapes the noodles, ensuring they fit completely within the bowl, thus maintaining the product's integrity and appearance.

In each noodles projects, the designed of distributing machanism is customized packaging styles from customers.

After the initial processing, an extra set of shaping mechanisms gives the rice noodles their perfect form. Following this, the drying process solidifies the noodles into a cake shape, ready for packaging and distribution.

The rice noodle packaging machine which is Automatic Feeding, Weighing, Bowl Filling, Shaping, and Drying by Smart Weigh marks a significant leap in food packaging technology. By addressing key issues such as labor efficiency, precision, and hygiene, this system not only enhances productivity but also ensures the highest quality of the final product. It stands as a testament to Smart Weigh's commitment to innovation and excellence in the packaging industry.

For businesses looking to elevate their rice noodle packaging process, or for those interested in learning more about Smart Weigh's innovative instant rice noodle packaging machine solutions, contact us right now! Discover how Smart Weigh can transform your production process, ensuring efficiency, accuracy, and quality in every package.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved