Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

The snack industry is thriving, with the global market projected to reach $1.2 trillion by 2025. For medium and large-scale snack manufacturers, this presents immense growth opportunities—but also significant challenges. One major hurdle? An inefficient packing process that drains profits through high labor costs, frequent downtime, and inconsistent quality.

This case study explores how Our client, a medium-scale snack manufacturer, overcame these obstacles with Smart Weigh's unmanned automatic chips packaging system. From outdated operations to cutting-edge automation, discover how they achieved remarkable efficiency gains. Looking to optimize your packaging process? Contact Smart Weigh today for a tailored consultation.

Heavy reliance on manual labor, leading to rising costs.

Frequent equipment breakdowns, causing costly production halts.

High defect rates, reducing product quality and consistency.

Limited scalability, restricting their ability to meet growing demand.

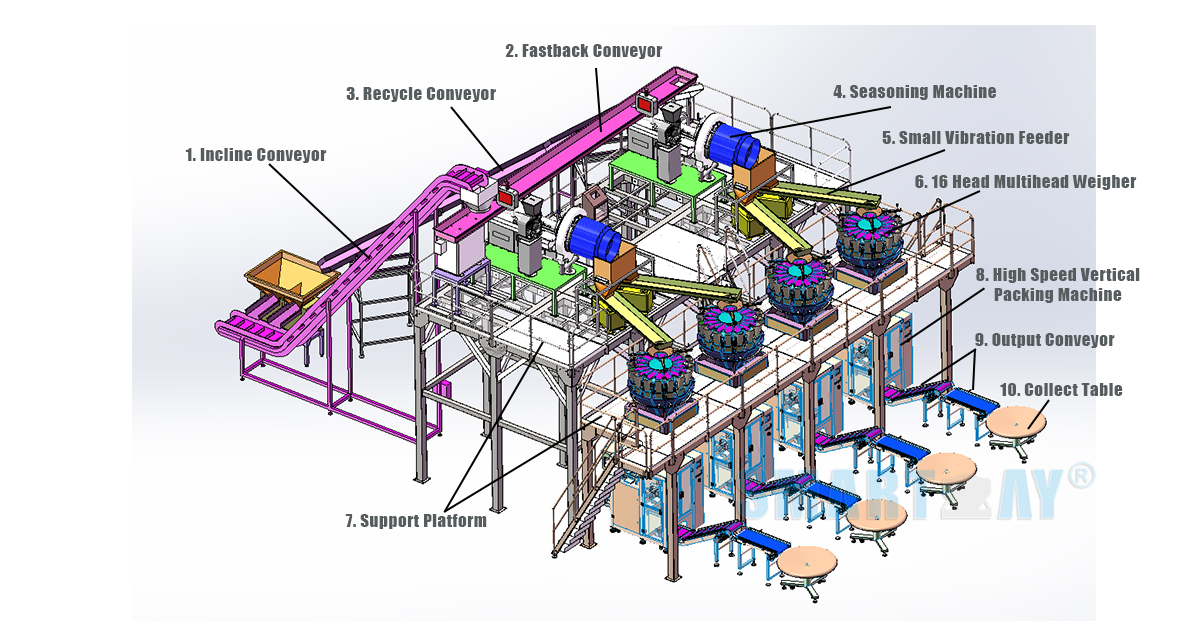

Incline Conveyor – Eliminates manual handling, reducing labor costs.

Recycle Conveyor – Creates a closed-loop system to minimize waste and optimize resources.

Online Seasoning Adjustment – Ensures real-time tweaks for consistent flavor and quality.

Fastback Conveyor – Reduces breakage and enhances hygiene for superior product standards.

High-Speed Packing – Capable of handling up to 500 bags per minute, significantly boosting output.

Multihead Weigher Integration – Ensures precise weight measurements, reducing material wastage.

Automated Bagging & Sealing – Enhances efficiency with airtight, uniform packaging.

Smart Control System – Allows real-time monitoring and adjustments for peak performance.

| Weight | 30-90 grams/bag |

| Speed | 100 packs/min with nitrogen for each 16 head weigher with high speed vertical packing machine, total capacity 400 packs/min, it means that 5,760- 17,280 kg. |

| Bag Style | Pillow bag |

| Bag Size | Length 100-350mm, width 80-250mm |

| Power | 220V, 50/60HZ, single phase |

Initial Assessment – Analyzed the existing system to identify inefficiencies.

Custom System Design – Tailored the solution to match their production goals and space constraints.

Installation & Integration – Minimal disruption ensured a smooth transition.

Comprehensive Staff Training – Workers quickly adapted to the new system.

Testing & Optimization – Fine-tuned performance for a flawless launch.

30% Increase in Packing Speed – Higher output per hour.

25% Reduction in Labor Costs – Lower reliance on manual work.

40% Decrease in Downtime – Enhanced equipment reliability.

15% Fewer Defects – Improved quality control and consistency.

Embrace Automation – Reduce costs and boost efficiency.

Work with Industry Experts – Partnering with a trusted provider like Smart Weigh ensures tailored solutions.

Prioritize Scalability – Choose systems that grow with your business.

Focus on Quality & Hygiene – Features like the Fastback Conveyor ensure top-tier product standards.

Our client's success with Smart Weigh’s automated packaging system showcases the power of automation. With a 30% speed boost, 25% labor savings, 40% less downtime, and 15% fewer defects, they didn't just fix inefficiencies—they built a foundation for future growth.

If you're a snack manufacturer struggling with outdated systems, Smart Weigh has the solution. Don't let inefficiencies hold you back. Contact Smart Weigh today for a consultation—visit Smart Weigh Contact Page or call [insert phone number] to get started.

Let's revolutionize your snack manufacturing together!

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved