Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

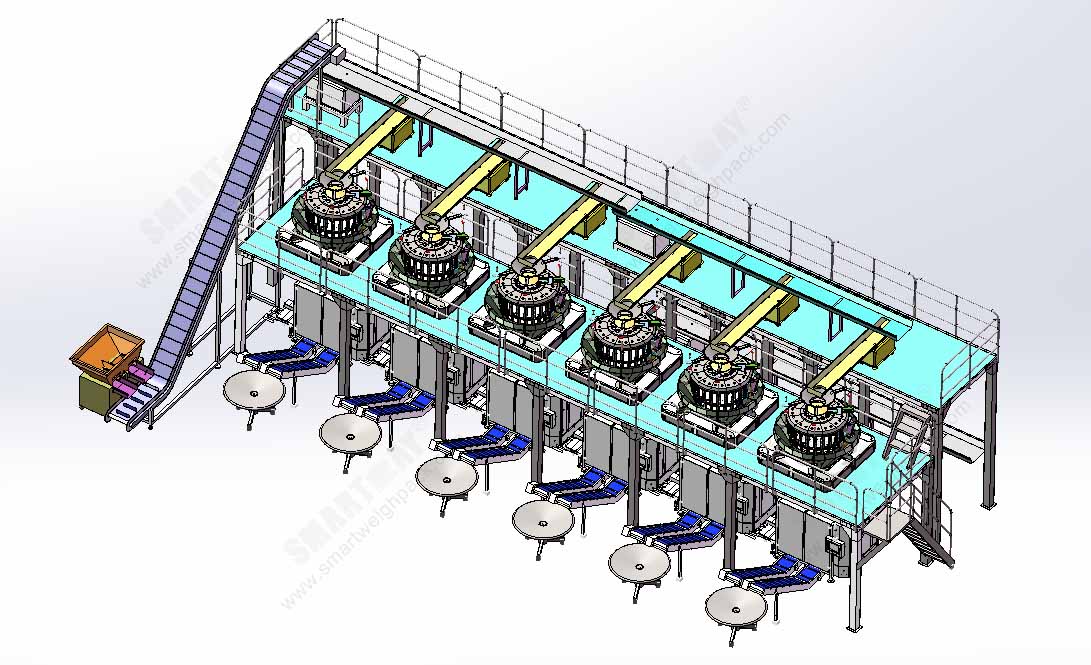

Designing an efficient and effective packaging line involves a series of strategic steps. Each phase is essential to ensure that the packaging line operates smoothly and meets the specific needs of your production environment. Smart Weigh follows a comprehensive approach that ensures every element of the packaging line is considered, tested, and optimized for maximum performance. Below are the critical steps involved in the packaging line design process.

Before designing a packaging line, it is crucial to understand the product's specific requirements, as well as the type of packaging needed. This step includes:

Product Specifications: Identifying the size, shape, fragility, and material properties of the product. For example, liquids, granules, or powders may require different handling equipment.

Packaging Types: Deciding on the type of packaging material—such as pillow bags, premade pouches, bottles, jars, etc.—and ensuring compatibility with the product.

Quantity and Speed: Determining the required production volume and packaging speed. This helps determine the necessary machinery and system capacity.

By understanding the product and its packaging requirements in detail, Smart Weigh ensures that the design will meet both performance and safety standards.

Once the product specifications and packaging types are understood, the next step is to evaluate the existing facilities and workflow. This step helps to identify potential challenges or opportunities for improvement in the current production environment. Key factors to consider include:

Available Space: Understanding the size and layout of the facility to ensure that the packaging line fits seamlessly within the available space.

Current Workflow: Analyzing how the existing workflow operates and identifying potential bottlenecks or areas of inefficiency.

Environmental Considerations: Ensuring that the packaging line meets regulatory requirements for hygiene, safety, and environmental standards (such as sustainability).

Smart Weigh's design team works with clients to assess these factors and ensure that the new line fits into the existing production flow.

The equipment selection process is one of the most critical steps in packaging line design. Different products and packaging types require different machines, and Smart Weigh carefully selects equipment based on your needs. This step includes:

Filling Machines: For products like powders, granules, liquids, and solids, Smart Weigh selects the most suitable filling technology (e.g., auger fillers for powders, piston fillers for liquids).

Sealing and Capping Machines: Whether it’s bag sealing, pouch sealing, or bottle capping, Smart Weigh ensures the chosen machinery delivers high precision, quality seals, and meets product specifications.

Labeling and Coding: Depending on the type of packaging, labeling machines must be selected to ensure precise and consistent placement of labels, barcodes, or QR codes.

Automation Features: From robotic arms for picking and placing to automated conveyors, Smart Weigh integrates automation where needed to improve speed and reduce manual labor.

Each machine is carefully chosen based on the product type, packaging material, speed requirements, and facility constraints, ensuring it fits the specific needs of the production line.

The layout of the packaging line is crucial for optimizing production efficiency and minimizing downtime. An effective layout will ensure a smooth flow of materials and reduce the likelihood of congestion or delays. This phase involves:

Flow of Materials: Ensuring that the packaging process follows a logical flow, from the arrival of raw materials to the final packaged product. The flow should minimize the need for material handling and transportation.

Machine Placement: Strategically placing equipment so that each machine is easily accessible for maintenance, and to ensure that the process moves logically from one stage to the next.

Ergonomics and Worker Safety: The layout should consider the safety and comfort of workers. Ensuring proper spacing, visibility, and ease of access to equipment reduces the chance of accidents and improves operator efficiency.

Smart Weigh uses advanced software tools to create and simulate the packaging line layout, making adjustments as necessary to ensure optimal performance.

Packaging line design today requires the integration of cutting-edge technologies to meet the demands of modern production. Smart Weigh ensures that automation and technology are properly integrated into the design. This may include:

Automated Conveyors: Automated conveyor systems move products through different stages of the packaging process with minimal human intervention.

Robotic Pick and Place Systems: Robots are used to pick products from one stage and place them onto another, reducing labor costs and speeding up the process.

Sensors and Monitoring Systems: Smart Weigh integrates sensors to monitor product flow, detect issues, and make adjustments in real time. This ensures that the packaging line operates smoothly and any issues are quickly addressed.

Data Collection and Reporting: Implementing systems that collect data on machine performance, output speed, and downtime. This data can be used for continuous improvement and predictive maintenance.

By integrating the latest technologies, Smart Weigh helps companies automate repetitive tasks, reduce human error, and improve overall throughput.

Before the final packaging line is set up, Smart Weigh tests the design through prototyping. This step allows the design team to run trials and evaluate the performance of the machines and layout. Key tests include:

Simulated Production Runs: Conducting trial runs to ensure that all machinery works as expected and that products are packaged correctly.

Quality Control: Testing the packaging for consistency, accuracy, and durability to ensure that the products meet the required standards.

Troubleshooting: Identifying any issues in the system during the prototype phase and making adjustments before finalizing the design.

By prototyping and testing, Smart Weigh ensures that the packaging line is fully optimized for efficiency and quality.

Once the design has been finalized, the packaging line is installed and commissioned. This phase involves:

Machine Installation: Installing all necessary machines and equipment according to the layout plan.

System Integration: Ensuring that all machines and systems work together as one cohesive unit, with proper communication between machines.

Testing and Calibration: After installation, Smart Weigh performs thorough testing and calibration to ensure all equipment is functioning correctly and that the packaging line is running at optimal speed and efficiency.

To ensure your team can effectively operate and maintain the new packaging line, Smart Weigh provides comprehensive training. This includes:

Operator Training: Teaching your team how to use the machines, monitor the system, and troubleshoot any issues that arise.

Maintenance Training: Providing knowledge on routine maintenance tasks to keep the machines running smoothly and prevent unexpected breakdowns.

Ongoing Support: Offering post-installation support to ensure the line operates as expected and assisting with any necessary updates or improvements.

Smart Weigh is committed to providing continuous support to ensure the long-term success of your packaging line.

Packaging line design is not a one-time process. As your business grows, Smart Weigh provides ongoing optimization services to improve performance, increase speed, and reduce costs. This includes:

Monitoring Performance: Using advanced monitoring systems to track performance and identify areas for improvement.

Upgrades: Integrating new technologies or equipment to keep the packaging line at the cutting edge.

Process Optimization: Continuously evaluating the workflow to ensure that it meets production goals and operates at maximum efficiency.

With Smart Weigh's commitment to continuous improvement, your packaging line will remain flexible, scalable, and ready to meet future demands.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved