The Ultimate Guide to Automated Weighing Systems for Prepared Meal Manufacturers

Introduction: How Automation Is Revolutionizing Prepared Meal Manufacturing

The prepared meal industry thrives on speed, consistency, and compliance. As demand for perfectly portioned, restaurant-quality meals continues to rise, manufacturers are seeking ways to eliminate inefficiencies in production. Traditional methods, like manual scales and static weighers, often lead to errors, waste, and bottlenecks in the production process. Automated weighing systems—specifically belt combination weighers and multihead weighers—are transforming food production. These systems allow manufacturers to handle diverse ingredients with precision, ensuring perfect portioning, greater efficiency, and compliance with stringent regulations.

What Are Automated Weighing Systems?

Automated weighing systems are machines designed to accurately measure and portion ingredients or finished products without manual intervention. These systems integrate smoothly with production lines, increasing speed, reducing waste, and maintaining consistency. They are particularly beneficial for prepared meal manufacturers, who need precise control over everything from diced vegetables to marinated proteins.

Types of Automated Weighing Systems for Prepared Meals: Belt Combination Weighers & Multihead Weighers

For prepared meal manufacturers, belt combination weighers and multihead weighers are the most effective automated systems for ensuring both speed and accuracy in portioning.

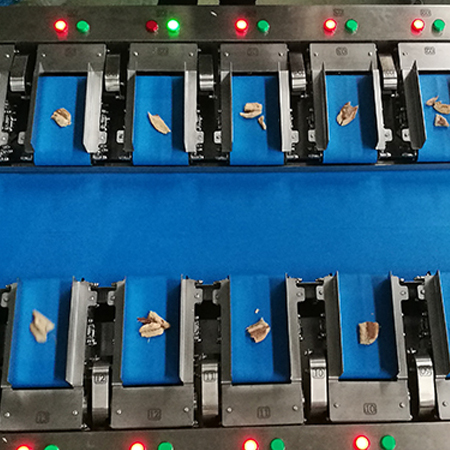

A. Belt Combination Weighers (Linear Belt Weighers)

How They Work

Belt combination weighers use a conveyor belt system to transport products through a series of weighing hoppers. These systems feature dynamic sensors and load cells that continuously measure product weight as it moves along the belt. A central controller calculates the optimal combination of weights from multiple hoppers to achieve the target portion size.

Ideal Applications for Prepared Meals

Bulk Ingredients: Perfect for free-flowing ingredients like grains, frozen vegetables, or diced meats.

Irregularly Shaped Items: Handles items such as chicken nuggets, shrimp, or sliced mushrooms without jamming.

Low-Volume or Small-Scale Production: Ideal for businesses with smaller production volumes or lower cost-investment needs. This system allows for efficient handling of smaller batch sizes at a lower investment cost.

Flexible Production: Suited for operations where flexibility and low investment are key factors.

Key Benefits

Continuous Weighing: Products are weighed on-the-go, eliminating downtime associated with manual weighing.

Flexibility: Adjustable belt speeds and hopper configurations allow for easy handling of varying product sizes.

Easy Integration: Can sync with downstream equipment like Tray Denester, Pouch Packing Machine or vertical form fill seal (VFFS) machine, ensuring end-to-end automation.

![The Ultimate Guide to Automated Weighing Systems for Prepared Meal Manufacturers 1]()

![The Ultimate Guide to Automated Weighing Systems for Prepared Meal Manufacturers 2]()

Example Use Case

A small meal kit manufacturer uses a belt combination weigher to portion 200g of quinoa into pouches, handling 20 portions per minute with ±2g accuracy. This system reduces giveaway costs by 15%, offering an affordable solution for smaller production lines.

B. Multihead Weighers

How They Work

Multihead weighers consist of 10–24 weighing hoppers arranged in a circular configuration. The product is distributed across the hoppers, and a computer selects the best combination of hopper weights to meet the target portion. Excess product is recycled back into the system, minimizing waste.

Ideal Applications for Prepared Meals

Small, Uniform Items: Best for products like rice, lentils, or cubed cheeses, which require high precision.

Precision Portioning: Perfect for calorie-controlled meals, such as 150g portions of cooked chicken breast.

Hygienic Design: With stainless steel construction, multihead weighers are designed to meet strict sanitation standards for ready-to-eat meals.

High-Volume or Large-Scale Production: Multihead weighers are ideal for large manufacturers with consistent, high-volume production. This system is optimal for stable and high-output production environments where precision and speed are essential.

Key Benefits

Ultra-High Accuracy: Achieves ±0.5g precision, ensuring compliance with nutritional labeling laws and portion control.

Speed: Can process up to 120 weighments per minute, far outpacing manual methods.

Minimal Product Handling: Reduces contamination risks for sensitive ingredients like fresh herbs or salads.

Example Use Case

A large-scale frozen meal producer uses ready meal packaging system from Smart Weigh features a multihead weigher that automates the weighing and filling of various ready-to-eat foods such as rice, meat, vegetables, and sauces. It works seamlessly with tray sealing machines for vacuum sealing, offering up to 2000 trays per hour. This system boosts efficiency, reduces labor, and improves food safety through vacuum packaging, making it ideal for packaging cooked meals and ready-to-eat food products.

Key Benefits of Automated Weighing Systems

Both belt combination weighers and multihead weighers offer substantial advantages for prepared meal manufacturers:

Accuracy: Reduce giveaway, saving 5–20% in ingredient costs.

Speed: Multihead weighers process 60+ portions/minute, while belt combination weighers handle bulk items continuously.

Compliance: Automated systems log data that is easily auditable, ensuring adherence to CE or EU regulations.

How to Choose Between Belt vs. Multihead Weighers

Choosing the right system depends on several factors, including product type, speed requirements, and accuracy needs. Here’s a comparison to help you decide:

| Factor | Belt Combination Weigher | Multihead Weigher |

|---|---|---|

| Product Type | Irregular, bulky, or sticky items | Small, uniform, free-flowing items |

| Speed | 10–30 portions/minute | 30–60 portions/minute |

| Accuracy | ±1–2g | ±1-3g |

| Production Scale | Small-scale or low-investment operations | Large-scale, stable production lines |

Implementation Tips

When implementing automated weighing systems in your production line, consider the following tips:

Test with Samples: Run trials using your product to evaluate system performance and ensure optimal results.

Prioritize Cleanability: Choose systems with IP69K-rated components for easy cleaning, especially if the system will be exposed to wet environments.

Demand Training: Ensure that suppliers provide comprehensive onboarding for both operators and maintenance staff to maximize system uptime.

Conclusion: Upgrade Your Production Line with the Right Weighing System

For prepared meal manufacturers, belt combination weighers and multihead weighers are game-changers. Whether you’re portioning bulk ingredients like grains or precise portions for calorie-controlled meals, these systems deliver unmatched speed, accuracy, and return on investment. Ready to upgrade your production line? Contact us for a free consultation or demo tailored to your specific needs.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine