Impushana yokuhlanza isithole ukuthandwa emhlabeni wonke, ikakhulukazi ngoba iyonga emazweni asathuthuka. Imishini yesimanje yokupakisha okokuhlanza ikhombisa ukuthuthuka kwale mboni. Le mishini ingagcwalisa izikhwama ezingama-20-60 ngomzuzu ngokunemba okunembile.

Imishini yokupakisha namuhla iphatha yonke into kusukela kuzinto zokuhlanza okuyimpushana kuya ekwakhekeni koketshezi kanye nama-pods asetshenziswa kanye. Izinzwa ezihlakaniphile nobuchwepheshe be-IoT zenze le mishini yaba ngcono ekuzivumelaniseni nezidingo ezahlukene. Badinga futhi isikhathi esincane sokuphumula ngoba bangakwazi ukubikezela ukuthi ukunakekelwa kuyadingeka nini.

Lo mhlahlandlela ophelele uhlola ukuthi uwenza kanjani ngendlela oyifisayo umshini wokupakisha olungile wesitshalo sakho. Uzofunda ukufanisa izidingo zakho zokusebenza futhi uthuthukise ukukhiqiza ngempumelelo.

Umshini wokupakisha okokuhlanza uwumshini oklanyelwe ukupakisha izihlanzi eziyimpuphu noma eziwuketshezi ngendlela efanele futhi enembile. Ingena ngaphansi kokugcwalisa ifomu kanye ne-seal (FFS) futhi yaziwa nangokuthi umshini wokupakisha oyimpushana. Ingenye yezingcezu zemishini ebaluleke kakhulu embonini yokupakisha engakhipha impushana/uketshezi, yenze amaphakheji, futhi igcwalise imikhiqizo konke ngesikhathi esisodwa.

Imishini yokupakisha okokuhlanza iyatholakala ngezinguqulo ezizenzakalelayo/ezizenzakalelayo ezinomumo ovundlile noma oqondile nazo zonke izici ezinikeza ukusebenza kahle okuhle kakhulu. Kuye ngomphakeli, umshini wokugcwalisa okokuhlanza ungenziwa ngokwezifiso ukuze uhlangabezane nezidingo zomthengi futhi ungahlonywa izesekeli ezithuthukisiwe ukuze unciphise amaphutha njengezidingo zokulawula.

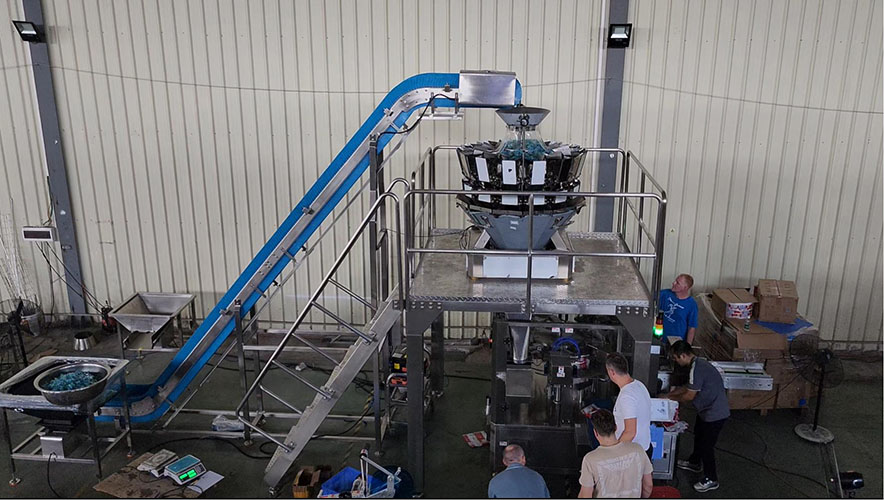

<umshini wokupakisha okokuhlanza产品图片>

Izitshalo ezikhiqizayo namuhla zibhekene nengcindezi ekhulayo yokuletha ikhwalithi engaguquki futhi zihlangabezane nezidingo zemakethe. Imishini yokupakisha izinto zokuhlanza ezizenzakalelayo iyimishini ebalulekile yezitshalo ezifuna ukuthuthukisa ukusebenza kwazo.

Le mishini ikhulisa kakhulu umthamo wokukhiqiza ngemisebenzi enesivinini esiphezulu efinyelela imivimbo engama-60 ngomzuzu. Amasistimu azenzakalelayo enza imisebenzi eminingi ngesikhathi esisodwa futhi ahlanganisa ukulebula, ukubeka uphawu, nokuhlola ikhwalithi kube inqubo eyenziwe lula.

Ukulawulwa kwekhwalithi kudlala indima ebalulekile emisebenzini yokupakisha okokuhlanza. Imishini yesimanje isebenzisa izinzwa eziyinkimbinkimbi kanye nezinhlelo zokulawula ukuze kuqinisekiswe ukugcwaliswa okunembile kanye nesisindo. Lawa masistimu abe esegcina ukufana komkhiqizo kuwo wonke amaqoqo, okunciphisa amaphutha futhi kugcine amazinga ekhwalithi engashintshi.

Imishini yokupakisha okokuhlanza iletha izinzuzo ezinkulu zezomnotho. Amasistimu anciphisa izindleko zabasebenzi ngokusebenzisa i-automation. Baphinde bathuthukise ukusetshenziswa kwezinto ezibonakalayo ngokubala izinto zokupakisha ezidingekayo kumkhiqizo ngamunye. Izitshalo zonga ezindlekweni zokusebenza ngoba amasistimu azenzakalelayo asebenza ngokuqhubekayo ngaphandle kwekhefu noma izinguquko zamashifu.

Ukuphepha kwenza le mishini ibe yimpahla ebalulekile. Amasistimu okupakisha azenzakalelayo:

● Nciphisa ukuchayeka kwabasebenzi kumakhemikhali angaba yingozi

● Yehlisa ukulimala kokunyakaza okuphindaphindiwe

● Faka izithiyo zokuvikela kanye nezindlela zokumisa izimo eziphuthumayo

● Faka amasistimu wokukhiya ukuze uvikeleke ekusebenzeni

Le mishini izonikeza indawo yokusebenza ephephile ngokukhawulela ukuthintana kwabantu ngokuqondile nemikhiqizo ngesikhathi sokupakishwa. Izinzwa zamehlo nokuhlolwa kwesisindo kuqinisekisa ukuthi iphakheji ngayinye ihlangabezana nokucaciswa kwekhwalithi ngaphambi kokushiya umugqa wokukhiqiza.

Ukuguquguquka kokukhiqiza kunikeza abakhiqizi enye inzuzo ebalulekile. Imishini yesimanje yokupakisha okokuhlanza ijwayela ngokushesha kumafomethi okupakisha nosayizi abahlukene. Abakhiqizi bangaphendula ngokushesha ezidingweni zemakethe futhi baqalise ukuhluka kwemikhiqizo emisha ngesikhathi sokuphumula esincane.

Abakhiqizi abafuna izixazululo zokupakisha okusheshayo banemishini eminingana ekhethekile yokupakisha okokuhlanza abangakhetha kuyo. Umshini ngamunye unikeza izinhlelo zokusebenza ezithile futhi uhlangabezana nezidingo ezihlukene zokukhiqiza.

Imishini ye-VFFS ihamba phambili ekuguquguqukeni kanye nesivinini ekusebenzeni kokupakisha. Lezi zinhlelo zakha izikhwama ngefilimu yesitoko esiyisicaba futhi ziwavale ngenqubo eyodwa ebushelelezi. Imishini yesimanje ye-VFFS ingakhiqiza izikhwama ezingama-40 kuya kweziyi-1000 ngomzuzu. Ama-opharetha angashintsha phakathi kosayizi abahlukene bezikhwama ngemizuzu esikhundleni samahora ngenxa yezici zokushintsha ezingenamathuluzi.

Amasistimu wokupakisha ajikelezayo akhanya kuzilungiselelo zokukhiqiza zevolumu ephezulu. Baphatha ngokuzenzakalelayo imisebenzi yokuphakela, ukukala, nokuvala. Le mishini icubungula izikhwama ezingama-25-60 ngomzuzu ngokugcwalisa amavolumu angama-10-2500 amagremu. Izindawo zokuthintana nomkhiqizo zisebenzisa ukwakhiwa kwensimbi engagqwali ukuze kuqinisekiswe izindinganiso zokuhlanzeka nokuqina.

Ibhokisi kanye nemishini yokugcwalisa ingakwazi ukusebenza kangcono ngezihlanzi eziyimpuphu nemikhiqizo ye-granular. Anamakhanda amaningi okugcwalisa ukuze asebenze ngokushesha, kanye nezici ze-anti-drip kanye ne-anti-foam ukugcina inqubo ihlanzekile. Le mishini iphinde iqinisekise ukuthi inani elifanele ligcwaliswa ngaso sonke isikhathi futhi ibala ngokuzenzekelayo ukuze umsebenzi ube lula.

Imishini yokugcwalisa uketshezi isebenza ngoketshezi olunobukhulu obuhlukahlukene nezinhlobo zeziqukathi. Basebenzisa izindlela ezihlukene ngokususelwa ezidingweni zoketshezi, njengama-piston fillers oketshezi oluwugqinsi, ama-gravity filler kwabancane, kanye nezigcwali ezichichimayo ukugcina amazinga elingana. Ama-pump fillers nawo asetshenziswa ngoba angakwazi ukuphatha ubukhulu obuhlukahlukene. Le mishini iguquguquka futhi isebenza kahle emisebenzini eminingi yokufaka uketshezi.

Le mishini isebenzisa izici ezithuthukisiwe njengezinhlelo zokulawula izimoto ze-servo nezindlela zokugcwalisa ezisuka phansi ezivimbela ukukhihliza amagwebu. Ukunemba kokugcwalisa kuhlala ngaphakathi kokubekezelelana okungu-≤0.5% ukuze kuqinisekiswe ukukhishwa komkhiqizo okunembayo. Amasistimu amaningi asebenza ngama-nozzles okugcwalisa angama-4-20 futhi angakhiqiza amabhodlela ayi-1000-5000 ngehora ezitsheni ezingama-500ml.

Umshini wokupakisha okokuhlanza ulula futhi ulandela ukulandelana. Nasi isinyathelo ngesinyathelo:

● Ukulayisha Okubalulekile: Umshini ulungiselelwe ukusetha umthamo wezinto ezibonakalayo, izinga lokushisa lokuvala, nesivinini. Uma isisethiwe, okokuhlanza kuyalayishwa emshinini wokuphakela, futhi inqubo yokupakisha iyaqala.

● Isisindo Sezinto Ezibalulekile: Umshini wokuhlanza olayishiwe ube usuthuthwa uyiswe ku-hopper yomshini omkhulu ngephampu yevacuum kanye neshubhu elide lensimbi engagqwali. Isigcwalisi se-auger sibe sesikala into esetshenziswayo ngokuya ngamapharamitha asethiwe ngaphambili ukuze kuqinisekiswe isisindo esingaguquki.

● Ukwakhiwa Kwesikhwama: Izinto ezilinganisiwe zihlala kusigcwalisi se-auger kuze kube yilapho kuqala inqubo yokwakhiwa kwesikhwama. Ifilimu eyisicaba evela ku-roller yefilimu ifakwa ku-tube yokwenza isikhwama, lapho ibunjwa khona ibe yi-cylindrical shape. Isikhwama esakhiwe kancane siyehla, silungele ukugcwaliswa.

● Ukugcwaliswa Kwezinto Ezibalulekile: Uma indawo engaphansi yesikhwama ivalwe ngokushisa, okokuhlanza okulinganiselwe kukhishwa kuwo. Lokhu kuqinisekisa ukuthi okuqukethwe kuhambisana nenani elidingekayo.

● Ukuvala Isikhwama: Ngemva kokugcwalisa, idivayisi yokuvala ukushisa ivala phezulu kwesikhwama. Isikhwama siyasikwa ukuze sihlukaniswe nesikhwama esilandelayo emugqeni wokukhiqiza.

● Ukukhipha Isikhwama: Izikhwama eziqediwe ziya ebhandeni lokuthutha futhi ziqoqwe njengemikhiqizo eqediwe ukuze isatshalaliswe.

Umshini wokupakisha okokuhlanza ungahlukaniswa ngezigaba ezintathu eziyinhloko ngokusekelwe ohlotsheni lomkhiqizo wokuhlanza: umshini wokupakisha okokuhlanza izingubo, umshini wokupakisha oyimpushana yokuhlanza izingubo, nomshini wokupakisha wejeli lobuhlalu. Ngezansi ukuhlukaniswa okuningiliziwe kwezingxenye zesigaba ngasinye:

Imishini yokupakisha okokuhlanza izingubo iklanyelwe ukuphatha ukwakheka kweziwashi eziwuketshezi ngokunemba nokusebenza kahle. Afakwe izici ezenzelwe ukuhlangabezana nezidingo ezithile zokuphatha uketshezi lwe-viscous.

Isakhi | Incazelo |

Uhlelo Lokugcwalisa Uketshezi | Ilawula ukugcwaliswa okunembile koketshezi lokuhlanza emabhodleleni. |

Amaphampu noma ama-valve | Ilawula ukugeleza kwesihlanzi esiwuketshezi ukuze sigcwaliswe ngokunembile. |

I-Nozzle yokugcwalisa | Ikhipha uketshezi emabhodleleni ngokunemba ukugwema ukuchitheka |

I-Bottle Conveyor System | Ithutha amabhodlela ngezinqubo zokugcwalisa, ze-capping, kanye nokulebula. |

I-Cap Feeding System | Iphakela amakepisi esiteshini se-capping, iqinisekisa ukusebenza okuqhubekayo. |

I-Capping System | Izindawo kanye nama-seal caps emabhodleleni agcwele. |

Ibhodlela Orientation System | Iqinisekisa ukuthi amabhodlela aqondaniswe kahle ukuze agcwaliswe futhi afakwe i-capping. |

I-Bottle Infeed/Outfeed | Indlela yokufaka ngokuzenzakalelayo amabhodlela angenalutho emshinini nokuqoqa amabhodlela agcwele. |

I-Labeling System | Ifaka amalebula emabhodleleni agcwalisiwe nafakwe izimbotshana. |

Kuqediwe Ukuthumela Umkhiqizo | Iqoqa futhi ikhiphe izikhwama ezivaliwe ukuze isatshalaliswe. |

Imishini yokupakisha impushana yokuhlanza ikhethekile ngezimpushana ezomile, ezigeleza mahhala. Idizayini yabo iqinisekisa ukunemba ekukaleni nasekugcwaliseni, okubenza balungele imikhiqizo eyimbudumbudu.

Izingxenye Ezibalulekile:

Isakhi | Incazelo |

Iphaneli yokulawula | Inikeza ukucushwa okulula kokusebenza komshini, okuhlanganisa ukugcwalisa, ukuvala uphawu, kanye nesivinini. |

Umshini Wokudla | Idlulisela impushana yokuhlanza isuka ethangini langaphandle iye kumshini wokugcwalisa. |

Idivayisi yokugcwalisa i-Auger | Ikhipha amanani anembile okugeza okuyimpushana kuphakheji ngayinye. |

Isikhwama Sangaphambili | Ibumba impahla yokupakisha ibe yisikhwama esiyicylindrical. |

Idivayisi yokuvala | Inikeza ama-seal angangenisi umoya ukuze kugcinwe impushana iyintsha futhi ivikelekile |

Kuqediwe Ukuthumela Umkhiqizo | Iqoqa futhi ihlele izikhwama ezivaliwe ukuze zisakazwe. |

Imishini yokupakisha ye-laundry pod ibhekelela ama-pods asetshenziswa kanye noma ubuhlalu, iqinisekisa ukugcwaliswa okuphephile nokunembayo. Zenzelwe ukuphatha okuntekenteke kwemikhiqizo esekwe ngejeli.

Izingxenye Ezibalulekile:

Isakhi | Incazelo |

Uhlelo Lokuphakelayo | Iphakela ngokuzenzakalelayo amaphodi elondolo emshinini wokupakisha. |

Isistimu Yokugcwalisa Isisindo | Ilawula ukubekwa okunembile kanye nenani lama-pods emabhokisini. |

Uhlelo Lokugcwalisa Ibhokisi | Ubeka inombolo efanele yezingubo zokuwasha ebhokisini ngalinye. |

Ukuvala/Ukuvala Uhlelo | Vala ibhokisi ngemva kokuthi seligcwalisiwe, uqinisekise ukuthi livalwe ngokuphephile. |

Uhlelo Lokulebula | Ifaka amalebula emabhokisini, okuhlanganisa imininingwane yomkhiqizo nezinombolo zeqoqo. |

Udinga ukucabanga ngezinto ezimbalwa ezibalulekile ezithinta ukusebenza kahle kanye nekhwalithi yomkhiqizo lapho ukhetha umshini wokugcwalisa okokuhlanza ofanele.

Izici ezibonakalayo nezici zokugeleza zemikhiqizo yokuhlanza inquma ukuthi yimuphi umshini wokupakisha osebenza kangcono. I-viscosity yezihlanzi eziwuketshezi idlala indima ebalulekile - izigcwalisi zamandla adonsela phansi zisebenza kahle ngoketshezi olugeleza mahhala, kuyilapho izigcwali zephampu noma zepiston ziphatha imikhiqizo eminyene kangcono. Ukuminyana kwenqwaba yomkhiqizo kuthinta kokubili ukusebenza kahle kokupakisha nezindleko zokuthumela. Imikhiqizo enenqwaba yenqwaba isiza ukwehlisa izindleko zokupakisha nezokuthutha.

Amandla akho okukhiqiza anquma ukuthi iyiphi imishini okufanele uyikhethe. Umshini omile wokugcwalisa ifomu uphatha ubuningi be-10g kuya ku-300g ngempumelelo kumaphrojekthi amancane. Ukusebenza kwevolumu ephezulu kusebenza kangcono ngemishini esebenza kahle kakhulu engakwazi ukupakisha imikhiqizo engu-1kg ukuya ku-3kg. Okokusebenza kufanele kufane kokubili izidingo zakho zokukhiqiza zamanje kanye nezinhlelo zokukhula zesikhathi esizayo.

Iphakheji yokuhlanza yanamuhla iza ngamafomethi ahlukahlukene, futhi ngayinye idinga amakhono athile omshini. Izikhwama zokuma zikunikeza izinzuzo ezimbalwa, njengezindleko zempahla ephansi nendawo yokubeka kanye nokusimama okungcono ngokusetshenziswa kwepulasitiki okuncishisiwe.

Isakhiwo sesitshalo sakho sithinta kakhulu ukusebenza kahle komugqa wokupakisha. Isakhiwo sesikhungo kufanele sithuthukise ukuhamba komsebenzi futhi sinciphise izingqinamba zokukhiqiza. Nakuba izakhiwo zihluka phakathi kwezinsiza, kufanele ucabangele isikhala semishini yokukhiqiza, Izinsiza Zokugcina, izindawo zokupakisha, kanye namalabhorethri okulawula Ikhwalithi.

Izindleko zokuthenga zangempela ziyingxenye eyodwa nje yesamba semali oyitshalile. Ukuhlaziywa okuphelele kwezindleko zenzuzo kuhlanganisa izindleko zokulungisa, izingxenye ezisele, izindleko zokuthumela, nokuqeqeshwa. Izibalo ze-ROI kufanele zibandakanye ukonga kwabasebenzi, izinzuzo ezisebenza kahle zokukhiqiza, nokuthuthukiswa kwezinto ezibonakalayo. Amasistimu azenzakalelayo abonisa imbuyiselo enkulu ngezindleko eziphansi zabasebenzi kanye nokunemba okungcono kokupakisha.

Imishini yokupakisha eyenziwe ngokwezifiso ihlinzeka ngezinzuzo ezilinganisekayo ezithinta ngqo impumelelo yokusebenza kanye nokuncintisana kwemakethe. Lawa masistimu ayisipesheli aletha izinzuzo ezedlula ukusebenza okulula kokupakisha.

Imishini yokugcwalisa i-detergent ye-high-speed icubungula amanani amakhulu ngokushesha, ifinyelela isivinini samaphakethe ayi-100-200 ngomzuzu. Lesi sivinini esisheshayo esihlanganiswe nezindlela eziqondile zokukhipha impahla kunciphisa udoti wempahla ngama-98%. Imishini igcina isenzo sokugcwalisa ngokungaguquki futhi sinciphisa ubungozi bokuchichima noma ukugcwaliswa kancane kwamaphakethe.

Izixazululo zesimanje zokupakisha zibeka ukukhanga okubonakalayo kanye nokusebenziseka kalula kwabathengi kuqala. Imishini edizayinelwe ngokwezifiso idala amaphakheji adonsa abathengi ngezici ezifana ne-embossing, i-debossing, nokuphrinta isikrini se-premium. Le mishini ikhiqiza izinto zokupakisha ezihlala ziqinile kusuka efekthri kuya ezindlini zabathengi. Imishini isekela amafomethi okupakisha amasha, okuhlanganisa imiklamo ehlangene enciphisa izindleko zokuthumela kanye nendawo yokugcina.

Imishini yokugcwalisa ethuthukisiwe isebenzisa izinzwa nezilawuli ezizenzakalelayo ukuze kugcinwe amazinga aphezulu okunemba. Lawa masistimu afinyelela ukunemba kokugcwalisa ngokuhlukahluka okungaphansi kuka-1% kumazinga okubekezelelana. Sihlanganise izinhlelo zokuvikela zokuvikela ukuze sibone izinkinga ngaphambi kokuba zikhule, okunciphisa izindleko zokulungisa futhi kwenza okokusebenza kuhlale isikhathi eside.

Imishini yokupakisha eyenziwe ngokwezifiso ihlangabezana nezindinganiso eziqinile zomkhakha. Imishini iza nezici zokuphepha ezifana nezinketho zokupakisha ezikhanyayo nezitatimende ezijwayelekile zesixwayiso. Lawa masistimu asiza ukugcina ukuthobelana ngokuthi:

● Vikela ukuvalwa kwephakheji okudizayinelwe ukuphepha kwezingane

● Amalebula ezixwayiso asezingeni kanye nemiyalelo yosizo lokuqala

● Izindlela zokukhishwa ezibambezelekile zokuphepha okuthuthukisiwe

● Ukuhlanganiswa kwezinto ezibabayo kumafilimu ancibilikayo

Imishini ifaka amasistimu okuphatha ikhwalithi athembekile alandelela futhi alawule ikhwalithi kukho konke ukukhiqiza. Le ndlela ebanzi iqinisekisa ukuthi iqoqo ngalinye lihlangabezana nezidingo zokulawula kuyilapho igcina amazinga omkhiqizo engaguquki.

Ukuphepha nokuhambisana kubalulekile emaphaketheni ezinto zokuhlanza. I-Occupational Safety and Health Administration (OSHA) idinga ukuthi imishini ibe nonogada ukuze ivikele abasebenzi ezingxenyeni ezinyakazayo, izindawo zokuncinza, nezinye izingozi. Abaqashi kufanele bengeze lezi zindlela zokuvikela uma imishini ingezi nazo.

Ukulebula komkhiqizo kubalulekile ukuze kuthotshelwe. Iphakheji ngayinye yokuhlanza kufanele ifake:

● Igama lomkhiqizo nemininingwane

● Ulwazi lokuxhumana nomkhiqizi

● Uhlu lwesithako olufinyelelekayo

● Izilinganiso zephesenti lesisindo lezithako

● Izexwayiso ze-Allergen, uma kudingeka

● Izifunda eziningi zikhawulela okuqukethwe kwe-phosphate ezihlahleni zibe ngu-0.5%, ngakho imishini kufanele iphathe amafomula athile ngokunembile.

● IKhomishana Yokuphepha Komkhiqizo Wabathengi igunyaza izexwayiso ezicacile zengozi nemiyalo yokusebenzisa ngokuphephile.

● I-Environmental Protection Agency (EPA) ikhuthaza ukusebenza kwe-eco-friendly ngezinhlelo ezifana ne-Safer Choice, edinga izinqubo zokupakisha ezinembayo ukuze kugcinwe ikhwalithi yomkhiqizo.

Imithetho yokubonisa ngale njengomthetho wase-California we-Right to Know idinga uhlu lwezithako ezinemininingwane ku-inthanethi, ngakho imishini yokupakisha kufanele isekele amasistimu okulebula athuthukile. Ukuthobelana kuqinisekisa ukuphepha, umthwalo wemfanelo wendawo, kanye nolwazi olunembile lwabathengi.

I-Smart Weigh Pack igqama njengomholi othembekile embonini yokukala nokupakisha, enikeza izixazululo ezintsha eziklanyelwe izimboni eziningi. Yasungulwa ngo-2012. I-Smart Weigh inobuchwepheshe obungaphezu kweminyaka eyishumi futhi ihlanganisa ubuchwepheshe obusezingeni eliphezulu nokuqonda okujulile kwezidingo zemakethe ukuletha imishini enesivinini esikhulu, enembile, nethembekile.

Uhlu lwethu oluphelele lomkhiqizo luhlanganisa izikali ze-multihead, amasistimu wokupakisha aqondile, nezixazululo eziphelele ze-turnkey yezimboni zokudla nezingezona ezokudla. Ithimba lethu elinamakhono e-R&D kanye nonjiniyela abasekela umhlaba wonke abangama-20+ baqinisekisa ukuhlanganiswa okungenamthungo emugqeni wakho wokukhiqiza, okubhekelela izidingo zakho zebhizinisi ezihlukile.

Ukuzibophezela kwe-Smart Weigh kukhwalithi nokusebenza kahle kwezindleko kusizuzise ubambiswano emazweni angaphezu kuka-50, okufakazela amandla ethu okuhlangabezana namazinga omhlaba. Khetha i-Smart Weigh Pack ukuze uthole imiklamo emisha, ukwethembeka okungenakuqhathaniswa, nokusekelwa okungu-24/7 okunika ibhizinisi lakho amandla okukhulisa umkhiqizo kuyilapho wehlisa izindleko zokusebenza.

Ukutshala imali emshinini wokupakisha okokuhlanza ofanelana nezidingo zesitshalo sakho kungashintsha inqubo yakho yokukhiqiza. Le mishini inikeza ukusebenza kahle okungenakuqhathaniswa, ukuphepha, nokuhambisana, okuvumela abakhiqizi ukuthi bahlangabezane nezidingo zemakethe kuyilapho begcina izindinganiso zekhwalithi ephezulu.

Ngezixazululo ozenza ngokwezifiso ze-Smart Weigh Pack, ungaklama futhi usebenzise umshini ozifanela kahle izidingo zakho zokusebenza. Isitshalo sakho singafinyelela ukukhula okusimeme kanye nokuma kwemakethe okuncintisanayo ngokubeka phambili ukusungula izinto ezintsha nokunemba. Vakashela i-Smart Weigh Pack ukuze uhlole amathuba futhi uthathe isinyathelo sokuqala sokuthuthukisa imisebenzi yakho yokupakisha.

XHUMANA NATHI

Isakhiwo B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Sikwenza Kanjani Ukuhlangana Futhi Sichaze Umhlaba jikelele

Imishini Yokupakisha Ehlobene

Xhumana nathi, singakunikeza izixazululo ze-turnkey zokupakisha ukudla

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | Wonke Amalungelo Agodliwe