Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Detergent powder has gained popularity worldwide, especially because it's economical in developing nations. Modern detergent packaging machines show this industry's development. These machines can fill 20-60 bags per minute with exact precision.

Packaging machines today handle everything from powder detergents to liquid formulations and single-use pods. Smart sensors and IoT technology have made these machines better at adapting to different needs. They also need less downtime because they can predict when maintenance is needed.

This comprehensive guide explores how to customize the right detergent packing machine for your plant. You'll learn to match your operational needs and boost production output effectively.

A detergent packaging machine is a machine designed to pack powdered or liquid detergents efficiently and accurately. It falls under form fill and seal (FFS) and is also known as a powder packaging machine. It is one of the most important pieces of equipment in the packaging industry that can dispense powder/liquid, make packages, and fill products all in one go.

Detergent packaging machines are available in semi-automatic/automatic versions with horizontal or vertical orientation and all the features to give excellent work efficiency. Depending on the supplier, a detergent filling machine can be customized to meet the buyer’s requirements and can be equipped with advanced accessories to reduce errors as per regulatory requirements.

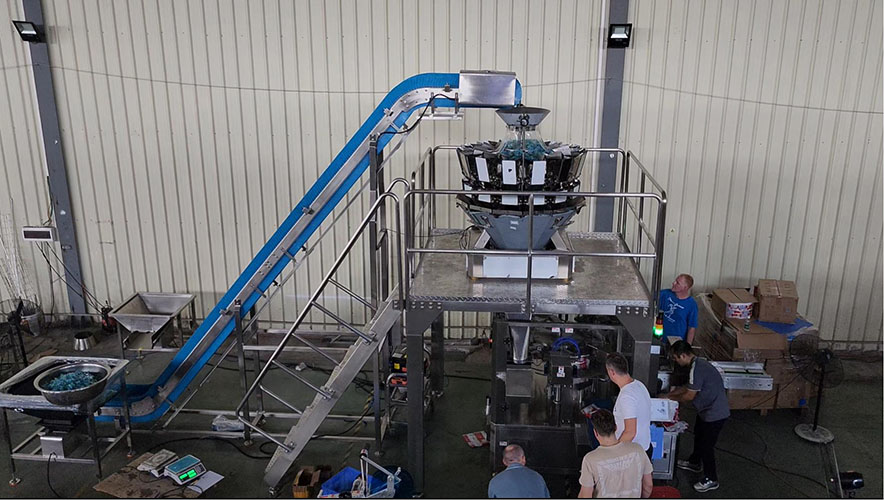

<detergent packing machine产品图片>

Manufacturing plants today face growing pressure to deliver consistent quality and meet market demands. Automated detergent packaging machines are vital equipment for plants that want to boost their operations.

These machines substantially increase production capacity with high-speed operations reaching 60 strokes per minute. The automated systems perform multiple tasks at once and combine labeling, sealing, and quality checks into a simplified process.

Quality control plays a key role in detergent packaging operations. Modern machines use sophisticated sensors and control systems to ensure precise filling and weighing. These systems then maintain product uniformity across batches, which reduces errors and keeps quality standards consistent.

Detergent packaging machines deliver substantial economic benefits. The systems cut labor costs through automation. They also optimize material usage by calculating the exact packaging materials needed for each product. Plants save on operational costs because automated systems work continuously without breaks or shift changes.

Safety makes these machines valuable assets. Automated packaging systems:

● Minimize worker exposure to potentially harmful chemicals

● Reduce repetitive motion injuries

● Incorporate protective barriers and emergency stop mechanisms

● Feature interlock systems for operational safety

These machines will give a safer workplace by limiting direct human contact with products during packaging. Optical sensors and weight checks make sure each package meets quality specifications before leaving the production line.

Production flexibility gives manufacturers another key advantage. Modern detergent packing machines quickly adapt to different packaging formats and sizes. Manufacturers can respond fast to market demands and launch new product variations with minimal downtime.

Manufacturers looking for quick packaging solutions have several specialized detergent packing machines to choose from. Each machine serves specific applications and meets different production needs.

VFFS machines excel at versatility and speed in packaging operations. These systems create bags from flat roll stock film and seal them in one smooth process. Modern VFFS machines can produce 40 to 1000 bags per minute. Operators can switch between different bag sizes in minutes instead of hours thanks to tool-free changeover features.

Rotary packaging systems shine in high-volume production settings. They handle material feeding, weighing, and sealing operations automatically. These machines process 25-60 bags per minute with filling volumes of 10-2500 grams. Product contact areas use stainless steel construction to ensure hygiene standards and durability.

Box and can filling machines work best with powder detergents and granular products. They have multiple filling heads to work faster, along with anti-drip and anti-foam features to keep the process clean. These machines also ensure the right amount is filled every time and have automatic counting to make the job easier.

Liquid filling machines work with liquids of different thicknesses and container types. They use different methods based on the liquid’s needs, such as piston fillers for thick liquids, gravity fillers for thinner ones, and overflow fillers to keep levels even. Pump fillers are also used because they can handle a variety of thicknesses. These machines are versatile and work well for many liquid packaging tasks.

These machines use advanced features like servo motor control systems and bottom-up filling methods that prevent foaming. The filling accuracy stays within ≤0.5% tolerance to ensure precise product dispensing. Most systems run with 4-20 filling nozzles and can produce 1000-5000 bottles per hour for 500ml containers.

The detergent packaging machine is simple and follows a sequence. Here’s a step-by-step:

● Material Loading: The machine is configured to set the material volume, sealing temperature, and speed. Once set, the detergent material is loaded into the feeding machine, and the packaging process starts.

● Material Weighing: The loaded detergent is then transported to the main machine’s hopper through a vacuum pump and a long stainless steel tube. The auger filler then measures the material according to the pre-set parameters to ensure consistent weight.

● Bag Formation: The measured material stays in the auger filler until the bag forming process starts. The flat film from the film roller is fed into the bag-forming tube, where it is formed into a cylindrical shape. The partially formed bag goes down, ready to be filled.

● Material Filling: Once the bottom of the bag is heat sealed, the measured detergent is dispensed into it. This ensures the content is according to the required quantity.

● Bag Sealing: After filling, the sealing device heat seals the top of the bag. The bag is then cut to separate it from the next bag in the production line.

● Bag Discharge: The finished bags go to the conveyor belt and are collected as finished products for distribution.

A detergent packaging machine can be divided into three main categories based on the type of detergent product: laundry detergent packing machine, detergent powder packaging machine, and laundry gel bead packaging machine. Below is a detailed breakdown of the components for each category:

Laundry detergent packaging machines are designed to handle liquid detergent formulations with precision and efficiency. They are equipped with features tailored to meet the specific requirements of handling viscous liquids.

Component | Description |

Liquid Filling System | Controls the precise filling of detergent liquid into bottles. |

Pumps or Valves | Regulates the flow of liquid detergent for accurate filling. |

Filling Nozzle | Dispenses liquid into bottles with precision to avoid spillage |

Bottle Conveyor System | Transports bottles through the filling, capping, and labeling processes. |

Cap Feeding System | Feeds caps to the capping station, ensuring continuous operation. |

Capping System | Places and seals caps onto the filled bottles. |

Bottle Orientation System | Ensures bottles are correctly aligned for filling and capping. |

Bottle Infeed/Outfeed | Mechanism for automatically feeding empty bottles into the machine and collecting filled bottles. |

Labeling Syste | Applies labels to the filled and capped bottles. |

Finished Product Conveyor | Collects and discharges sealed bags for distribution. |

Detergent powder packing machines are specialized for dry, free-flowing powders. Their design ensures precision in measuring and filling, making them ideal for granular products.

Key Components:

Component | Description |

Control Panel | Provides easy configuration of machine operations, including filling, sealing, and speed. |

Feeding Machine | Transfers detergent powder from an external tank to the filling mechanism. |

Auger Filling Device | Dispenses accurate amounts of powdered detergent for each package. |

Bag Former | Shapes the packaging material into a cylindrical bag. |

Sealing Device | Provides airtight seals to keep the powder fresh and secure |

Finished Product Conveyor | Collects and organizes sealed bags for distribution. |

Laundry pod packaging machines cater to single-use pods or beads, ensuring secure and precise filling. They are engineered for delicate handling of gel-based products.

Key Components:

Component | Description |

Feeder System | Automatically feeds the laundry pods into the packaging machine. |

Weighing Filling System | Controls the precise placement and quantity of pods into the boxes. |

Box Filling System | Places the correct number of laundry pods into each box. |

Sealing/Closing System | Seals the box after it has been filled, ensuring it is securely closed. |

Labeling System | Applies labels to the boxes, including product details and batch numbers. |

You need to think over several important factors that affect operational efficiency and product quality when choosing the right detergent filling machine.

The physical properties and flow characteristics of detergent products determine which packaging machine works best. Liquid detergents' viscosity plays a significant role - gravity fillers work well with free-flowing liquids, while pump or piston fillers handle thicker products better. The product's bulk density affects both packaging efficiency and shipping costs. Products with higher bulk density help reduce packaging and transportation expenses.

Your production capacity determines which machinery you should pick. A vertical form fill seal machine handles quantities of 10g to 300g effectively for small projects. High-volume operations work better with super-efficient machines that can package 1kg to 3kg products. The equipment should match both your current production needs and future growth plans.

Today's detergent packaging comes in various formats, and each needs specific machine capabilities. Stand-up pouches give you several advantages, such as Lower material costs and storage space and Better sustainability through reduced plastic usage.

Your plant's layout substantially affects packaging line efficiency. The facility design should improve workflow and reduce production bottlenecks. While layouts differ between facilities, you should consider space for manufacturing equipment, Storage facilities, Packaging areas, and Quality control laboratories.

The original purchase cost is just one part of your total investment. A full cost-benefit analysis covers maintenance expenses, spare parts, commissioning costs, and training. ROI calculations should include labor savings, production efficiency gains, and material optimization. Automated systems show substantial returns through lower labor costs and better packaging precision.

Customized detergent packaging machines provide measurable advantages that directly affect operational success and market competitiveness. These specialized systems deliver benefits that go beyond simple packaging functionality.

High-speed laundry detergent filling machines process large volumes quickly, reaching speeds of 100-200 packets per minute. This faster speed combined with precise dispensing mechanisms cuts material waste by up to 98%. The machines keep filling action consistent and minimize the risk of overflowing or underfilled packets.

Modern packaging solutions put visual appeal and consumer convenience first. Custom-designed machines create packages that draw consumers through features like embossing, debossing, and premium screen printing. These machines produce packaging that stays structurally sound from factory to consumer homes. The machines support innovative packaging formats, including compact designs that cut shipping costs and storage space.

Advanced filling machines use sensors and automated controls to maintain high accuracy levels. These systems achieve filling precision with less than 1% variation in tolerance levels. We integrated preventive maintenance programs to spot problems before they grow, which cuts repair costs and makes equipment last longer.

Customized packaging machines meet strict industry standards. The machines come with safety features like opaque packaging options and standardized warning statements. These systems help maintain compliance through:

● Secure package closures designed for child safety

● Standardized warning labels and first-aid instructions

● Delayed release mechanisms for enhanced safety

● Integration of bitter substances in soluble films

The machines feature reliable quality management systems that track and control quality throughout production. This comprehensive approach ensures each batch meets regulatory requirements while keeping product standards consistent.

Safety and compliance are essential in detergent packaging. The Occupational Safety and Health Administration (OSHA) requires machines to have guards to protect workers from moving parts, pinch points, and other hazards. Employers must add these safeguards if machines don’t come equipped with them.

Product labeling is crucial for compliance. Each detergent package must include:

● Product name and details

● Manufacturer contact info

● Accessible ingredient list

● Weight percentage ranges of ingredients

● Allergen warnings, if needed

● Many states limit phosphate content in detergents to 0.5%, so machines must handle specific formulas accurately.

● The Consumer Product Safety Commission mandates clear hazard warnings and instructions for safe use.

● The Environmental Protection Agency (EPA) encourages eco-friendly operations with programs like Safer Choice, requiring precise packaging processes to maintain product quality.

Transparency laws like California’s Right to Know Act require detailed ingredient lists online, so packaging machines must support advanced labeling systems. Compliance ensures safety, environmental responsibility, and accurate consumer information.

Smart Weigh Pack stands out as a trusted leader in the weighing and packaging industry, offering innovative solutions tailored to many industries. It was established in 2012. Smart Weigh has over a decade of expertise and combines cutting-edge technology with a deep understanding of market needs to deliver high-speed, accurate, and reliable machines.

Our comprehensive product range includes multihead weighers, vertical packaging systems, and complete turnkey solutions for food and non-food industries. Our skilled R&D team and 20+ global support engineers ensure seamless integration into your production line, catering to your unique business needs.

Smart Weigh's commitment to quality and cost-efficiency has earned us partnerships in over 50 countries, proving our ability to meet global standards. Choose Smart Weigh Pack for innovative designs, unmatched reliability, and 24/7 support that empower your business to increase productivity while reducing operational costs.

Investing in a detergent packaging machine tailored to your plant’s needs can revolutionize your production process. These machines offer unmatched efficiency, safety, and compliance, allowing manufacturers to meet market demands while maintaining high-quality standards.

With Smart Weigh Pack's customizable solutions, you can design and implement a machine that perfectly suits your operational requirements. Your plant can achieve sustainable growth and competitive market positioning by prioritizing innovation and precision. Visit Smart Weigh Pack to explore the possibilities and take the first step toward optimizing your packaging operations.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved