Imishini eqandisiwe yokupakisha ukudla isiphenduke izengezo ezibalulekile embonini yokudla, iqinisekisa ukuthi ukudla okuqandisiwe ngaphakathi kuhlala kumanzi futhi kusha isikhathi eside.

Le mishini iza ngosayizi nemiklamo ehlukahlukene ukuze ihlinzekele izinto ezidliwayo ezihlukene, kusukela ekudleni kwasolwandle kuya kwimifino nezithelo. Uma uzimisele ukuyithola, kuphoqelekile ukuthi uqale uqonde ukuthi yiluphi uhlobo oluzofanelana nawe kangcono.

Ngakho-ke, qhubeka ufunda, futhi kulo mhlahlandlela, sizocubungula zonke izici ezibalulekile okufanele uzazi ngomshini wokupakisha ukudla, okuhlanganisa izinhlobo zawo, izici ezibalulekile, izinzuzo, nezici okufanele uzicabangele.

Imishini yokupakisha ukudla eqandisiwe iza ngezinhlobo eziningi, kuhlanganisa nalezi ezilandelayo:

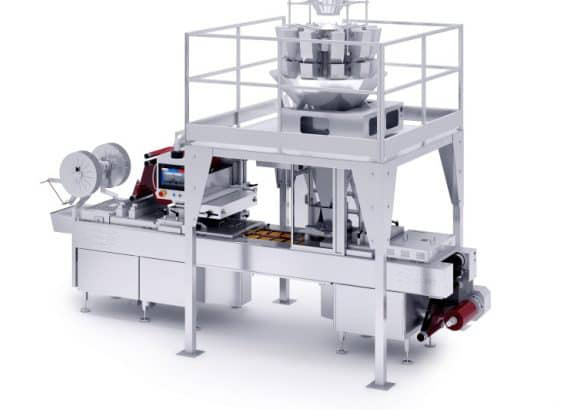

Umshini wokupakisha owenziwe kusengaphambili uvame ukusetshenziselwa ukudla kwasolwandle ngezikhwama zokuma nezikhwama. Igcwalisa ngokuzenzakalela amaphakethe enziwe kusengaphambili ngenani elithile lomkhiqizo kanye nezimpawu.

Lezi zimpahla zokupakisha ukudla eziqandisiwe nazo zinezikali ezinamakhanda amaningi ukuze zonke izikhwama zigcwaliswe ngobuningi obufanayo kanye nekhwalithi yomkhiqizo. Iqinisekisa iphethini ephelele namazinga aphezulu.

Ngesikhathi esifanayo, isistimu yokuvala igcina isikhathi sokupholisa esingaguquki kanye nokucindezela ukuze kutholwe ubuqotho bezimpawu.

I-Thermoforming ingolunye uhlobo oludumile lomshini wokupakisha ukudla opakisha ukudla okuqandisiwe kumathileyi aqinile.

Bashisisa ishidi lesikhwama sepulasitiki, balibumba libe yisimo sethreyi besebenzisa i-vacuum noma ingcindezi ngaphambi kokupakisha. Khona-ke ukudla okufriziwe kufakwa ethreyini, ukushisa kuvalwe ngeshidi elincane lepulasitiki phezulu.

Ilungele amabhizinisi abo bonke osayizi ngenxa yezindleko zayo eziphansi zamathuluzi kanye nendlela esebenza ngayo ephezulu.

Ama-tray sealer ahlinzeka ngomphumela ofanayo kakhulu nowomshini we-Thermoforming. Nokho, bapakisha ukudla emathileyini enziwe kusengaphambili esikhundleni sokuklama amasha.

Le nqubo ihlanganisa ukubeka ukudla okufriziwe ethreyini futhi ukuvale ngefilimu yepulasitiki encane kodwa enwetshiwe. Ngakho-ke kuqinisekisa ukupakishwa okungangenisi umoya okulungele ukudla okufriziwe okulungele ukudliwa.

Lezi zingasetshenzwa ngesandla noma ngomshini we-semi-automatic, okuzenza zibe inketho ephelele yokukhiqiza ivolumu ephansi.

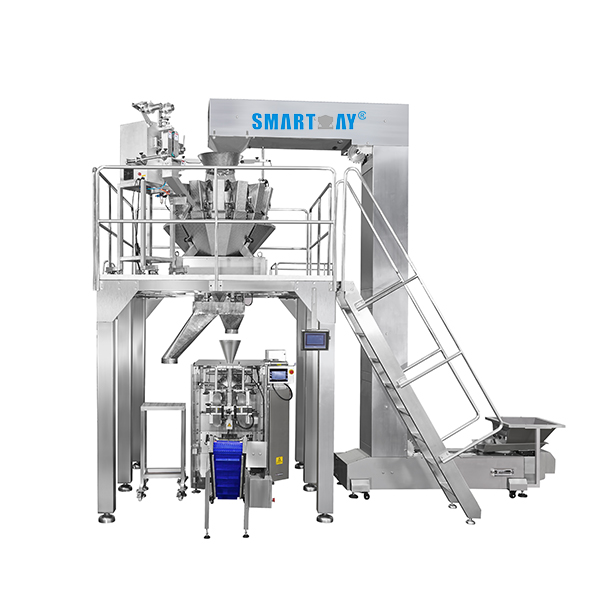

I-Vertical Form Fill Seal (VFFS) Umshini ungapakisha izinhlobo eziningi zokudla okuqandisiwe ngesikhathi esisodwa. Okufanayo yingakho lezi kuyizinhlobo ezivame ukusetshenziswa kakhulu zemishini yokupakisha ukudla- ikakhulukazi ezinhlanganweni ezinkulu.

Izikhwama ezimile zisebenzisa umqulu we-polyethylene noma izinto ezilayiniwe ukwenza izikhwama zomcamelo. Lezi zikhwama zibe sezigcwaliswa ngokudla okufriziwe, futhi zivalwe macala onke.

Le mishini i-othomathikhi kakhulu ukusiza ukukhiqizwa kwevolumu ephezulu phakathi nesikhathi esincane esingaba khona.

Ukuqinisekisa ukuthola umshini wokupakisha ofaneleka kahle webhizinisi lakho, qinisekisa ukuthi ubeka lezi zinto ezilandelayo ngaphansi kokucatshangwa:

Ukudla okufriziwe okuhlukile kudinga izidingo ezithile zokupakisha. Isibonelo, izinketho ezivalwe nge-vacuum zisebenza kahle kakhulu ezinyameni, kuyilapho ukupakishwa okuvalwe ngethreyi kulungele ukudla okulungiselelwe.

Amandla omshini kufanele ahambisane nezidingo zokukhiqiza. Ukusebenza kwevolumu ephezulu kudinga imishini ekwazi ukuphatha ukusetshenziswa okuqhubekayo ngaphandle kokubeka engcupheni ikhwalithi.

Usayizi womshini wokupakisha kufanele ulingane ngaphakathi kwendawo yakho ngaphandle kokuphazamisa eminye imisebenzi.

Uma ingqalasizinda yebhizinisi lakho inesikhala esilinganiselwe, hamba nemiklamo ehlangene. Kodwa-ke, uma unesikhala esiningi futhi ulungiselela ukukhiqizwa kwevolumu enkulu, khetha inketho enkulu.

Kubalulekile ukuhlola ukuthi umshini ungasebenza kahle yini endaweni ekhona yokukhiqiza.

Qinisekisa ukuthi le mishini yenziwe ukuze isebenze kahle ngaphakathi kwamazinga okushisa athile kanye nomswakama. Ukulawula izinga lokushisa okufanele akugcini nje ngokuqinisekisa ukuthi imishini isebenza kahle nangempumelelo kodwa futhi kugcina ikhwalithi nobuqotho bemikhiqizo epakishiwe.

Qiniseka ukuthi ucabangela izindleko zokusebenza nokonga okungaba khona kwesikhathi eside ukuze uvimbele ukulahlekelwa okungaba khona.

Khetha umshini onikeza inani elingcono kakhulu lemali oyitshalile. Ungakwazi ukunquma izindleko ezingaba khona ngevolumu yezinto onazo ku-inventory ozopakisha.

Qinisekisa ukuthi umshini uyahambisana nezinto ezithile ezidingekayo ukuze kulondolozwe ukudla okuqandisiwe. Lokhu kuhlanganisa amafilimu epulasitiki, amathreyi, noma izikhwama.

Khetha umshini onezidingo zokulungisa eziqondile. Bheka abathengisi abanedumela elihle ngenkonzo yabo yamakhasimende.

Ungakwazi ukwahlulela izinga lokwaneliseka kwekhasimende ngokufunda izibuyekezo zekhasimende kuwebhusayithi yalowo ongase abe umdayisi kanye nasemakhasini abo ezinkundla zokuxhumana.

Ikhono lokupakisha amanani amakhulu ngokushesha libalulekile ekusebenzeni okufunwa kakhulu. Isivinini ngaphandle kokudela ikhwalithi yisici esibalulekile.

Ukunemba ekukaleni, ukuvala, nokugcwalisa kunciphisa imfucuza futhi kuqinisekisa ukungaguquguquki. Lokhu kubalulekile ekugcineni isithunzi somkhiqizo.

Izinhlelo ezididiyelwe zokukala nokugcwalisa zithuthukisa ukusebenza kahle. Lezi zici ziqinisekisa ukuthi ukudla kuhlukaniswa ngokunembile kuwo wonke amaphakheji.

Lesi sici siqinisekisa ukupakishwa okungangenisi ngokuqedwa kochwepheshe. Kuphinde kunciphise isidingo sokungenelela ngezandla.

Amaphaneli okulawula anembile enza imisebenzi ibe lula, enciphisa isikhathi esidingekayo sokuqeqeshwa komsebenzisi. Amasistimu asebenziseka kalula athuthukisa ukukhiqiza jikelele.

Ukupakishwa ngendlela efanele kugcina ukusha, okwenza ukudla okuqandisiwe kuhlale kusebenziseka isikhathi eside. Lokhu kubaluleke kakhulu ezimakethe ezithumela ngaphandle.

Izindlela zokuvala zivimbela ukuchayeka komoya, kunciphisa ubungozi bokushiswa kwefriji. Lokhu kusiza ukugcina izinga lokuqala lokudla.

Ukupakisha okusebenzayo kuqinisekisa ukuthi ukudla okuningi kufinyelela kubathengi kusesimweni esihle. Lokhu kunciphisa ukulahlekelwa ngenxa yokonakala noma ukungcoliswa.

Ukupakisha kusebenza njengesithiyo, ukuvikela ukudla kumagciwane, uthuli, nokunye ukungcola. Lokhu kuqinisekisa ukuphepha kwabathengi.

Imiklamo ehlangene yonga indawo yokugcina neyokuthutha. Lokhu kunciphisa izindleko zokusebenza ngenkathi kuthuthukisa ukusebenza kahle.

Kafushane Imishini yokupakisha ukudla eqandisiwe iyingxenye ebalulekile embonini yesimanje yokudla. Bahlinzeka ngezinhlobo ezahlukene zokudla okuqandisiwe, kusukela enyameni kuye ezintweni zemifino, okuhlinzeka ngokuvikeleka okukhulu nokwelula impilo yeshalofu.

Ngesikhathi esifanayo, ukusebenza kwesivinini esiphezulu, ukunemba, kanye nezilawuli ezisebenziseka kalula kwenza le mishini ibaluleke kakhulu ekufakweni kokudla okufriziwe. Ezinye zezinketho ezidumile zifaka imishini yokupakisha yesikhwama esenziwe ngaphambili, imishini ye-thermoforming, ama-tray sealers, nemishini ye-VFFS. Uhlobo ngalunye lunezinzuzo zalo ezihlukile.

Kodwa-ke, umuntu kufanele ahlale egxile ekusebenzeni, ukunemba, kanye nokulungisa kalula lapho ekhetha umshini. Ukukhetha okulungile kuthuthukisa ukukhiqiza futhi kunciphisa izinselele zokusebenza.

Kusukela ekuvimbeleni ukushiswa kwamafriji kuya ekunciphiseni ukulahlwa kokudla, le mishini yenza izinguquko ekugcinweni nasekusatshalalisweni kokudla okuqandisiwe.

XHUMANA NATHI

Isakhiwo B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Sikwenza Kanjani Ukuhlangana Futhi Sichaze Umhlaba jikelele

Imishini Yokupakisha Ehlobene

Xhumana nathi, singakunikeza izixazululo ze-turnkey zokupakisha ukudla

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | Wonke Amalungelo Agodliwe