Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost.

Chips Bag Secondary Packaging Machine System

The snack industry's packaging needs are diverse and multifaceted, reflecting the wide variety of products and the competitive nature of the market. Packaging in this sector must not only preserve the freshness and quality of the snacks but also catch the consumer's eye and convey brand values effectively. Most of snacks manufacturers are focusing on the primary packaging, however, the secondary packaging is important too. Choosing the appropriate secondary packaging machine can ensure the effectiveness of potato chip bag packaging.

Secondary packaging serves a crucial function beyond just encasing individual chip bags. It provides additional protection during transportation, helps prevent damage, and ensures that products reach consumers in pristine condition. Moreover, secondary packaging offers substantial real estate for marketing, allowing brands to create eye-catching designs that stand out on retail shelves, thus enhancing brand recognition and driving sales.

Challenges in Secondary Packaging Machine for Chip Bags

Packaging chips presents unique challenges due to their fragile nature and the need to maintain bag integrity to prevent product damage and preserve freshness. The secondary packaging process must accommodate the air-filled bags, ensuring they are handled gently to avoid punctures or crushing. Balancing the efficiency of the packaging process with the delicacy required for handling chip bags is a key challenge that manufacturers must address.

Case Details

Chips bags net weight: 12 grams

Chips bag size: length 145mm, width 140mm, thickness 35mm

Target weight: 14 or 20 chips bag per package

Secondary packaging style: pillow bag

Secondary packaging size: width 400mm, length 420/500mm

Speed: 15-25 packs/min, 900-1500 packs/hour

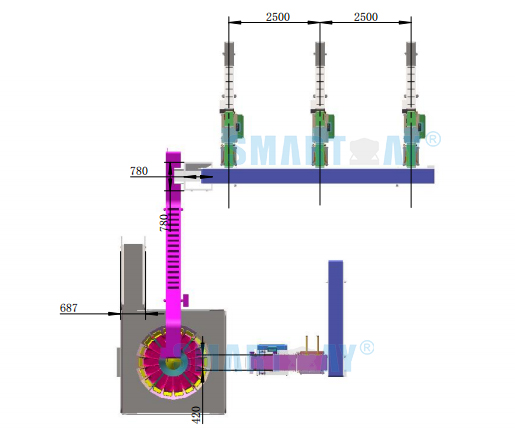

Overview of Chips Bag Secondary Packaging System

1. Conveyor distribution system with SW-C220 high speed checkweigher

2. Incline Conveyor

3. SW-ML18 18 Head Multihead Weigher with 5L Hopper

4. SW-P820 Vertical Form Fill Seal Machine

5. SW-C420 check weigher

Why Client Choose Smart Weigh?

Smart Weigh offers the right solution and comprehensive secondary packaging machinery.

Client in possession of primary packaging machines for chips are in search of a secondary packaging system. They require one that can seamlessly integrate with their existing machinery, thereby reducing the costs associated with manual packaging.

The current output of a single chips packaging machine is 100-110 packs per minute. Based on our calculations, one secondary packing machine can be linked with three sets of primary chips packaging machines. To facilitate this integration with three chips packaging lines, we have engineered a conveyor system equipped with a checkweigher.

Key Features of Secondary Packaging Machines for Chip Bags

Modern and smart secondary packing machines for chip bags come equipped with adjustable settings to handle various bag sizes and configurations. They seamlessly integrate with primary packaging lines, enhancing operational efficiency. Advanced detection systems in these machines ensure that only perfectly packaged products proceed to the market, maintaining high-quality standards.

Advantages of Automating Secondary Packaging Process for Chip Bags

Automating the secondary packing process offers significant advantages, including increased speed and efficiency, reduced labor costs, and minimized human error. Automated systems provide consistent packaging quality, which is crucial for fragile products like chip bags, leading to lower damage rates and improved customer satisfaction.

Trends and Innovations in Secondary Packaging for Chip Bags

The secondary packaging industry is evolving rapidly, with innovations like robotics, artificial intelligence, and machine learning improving efficiency and accuracy. Sustainability is also a key trend, with a growing emphasis on using eco-friendly materials and processes to reduce environmental impact. Additionally, market demands for various bag sizes and packaging styles are driving advancements in machine flexibility and capability.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425