Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

The client, a Malaysian maker of noodles, requested from Smart Weigh an automated weighing and packing solution to replace the previous manual weighing and packaging procedure and increase production capacity. They need noodles weighing filling system to connect with their exsiting noodle drying and packing system. We offer below machines to meet their request:

1. Noodle infeed conveyor

2. Noodle distributing system

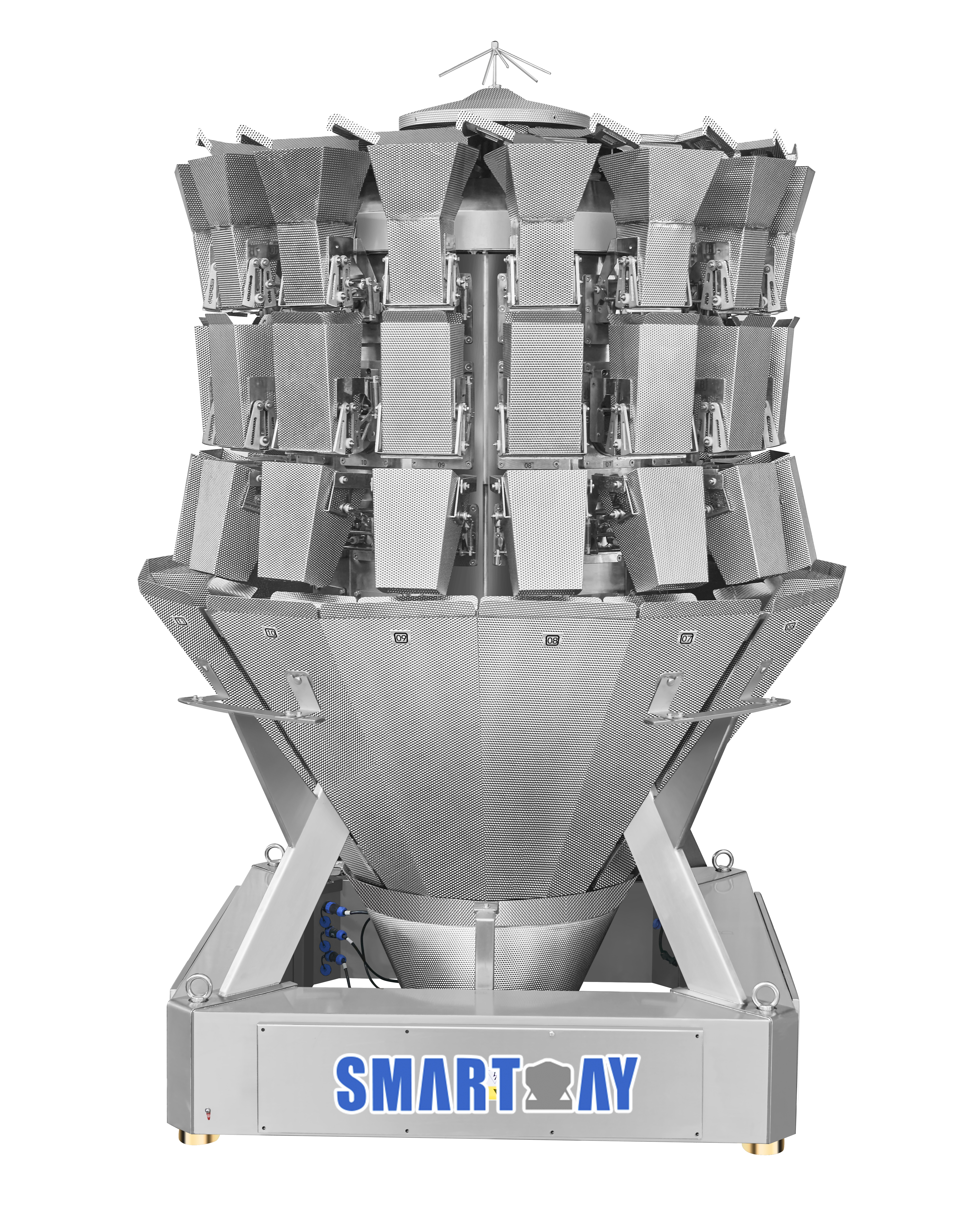

3. Noodles multihead weigher

4. Filling system (fill into 4 cups at one time)

5. Support platform

Customer makes 200-300mm long, fresh, wet noodles that are comparatively soft and have a stickiness tendency. Because it was difficult to cope with the normal multi-head weigher, we, Smart Weigh designed the unique noodle weighing machine that packing speed is 60 -100 packets in a minute(depends on the number of heads).

Maximum Weighing speed(BPM) | ≤60 BPM |

single weight | single weight |

Machine material | 304 stainless steel |

Power | Single AC 220V;50/60HZ;3.2kw |

HMI | 10.4 inch full color touch screen |

waterproof | Optional IP64/IP65 |

Automatic Grade | Automatic |

1. Strong amplitude linear feeder and a central top cone rotating at a high speed can help with material dispersion and help keep noodles from sticking.

2. Long soft products are distributed into the feed hopper with the assistance of the revolving rollers installed between each linear feeder pan. According to the features of the product, either automatic or manual adjustment of the linear feeding channels can be used.

3. The weighing sensor's resolution has been enhanced to two decimal places, allowing for high precision weighing and the ability to detect how well the products are being filled.

4. The discharge chute is slanted at a 60-degree angle to enhance the flow of the noodles, which can be fed swiftly. With the ability to dump products in staggered fashion to prevent blockages.

5. Memory hoppers have the ability to lower strong emission while increasing combination frequency.

6. All sections in touch with food can be manually dismantled for cleaning; IP65 waterproof system. The center support's thickness is increased to ensure stable machine operation.

7. It can enable multi-stage weight calibration and reduce operation failure thanks to the program recovery capability. Easy fault classification with a modular control system.

8. Electronic components are protected from humidity damage by an internal air pressure system. When there is no product, the machine can pause automatically.

Besides, we offer extra filling device for your customized packaging styles, includes instant cup packages(like this case), premade pouches, pillow bags, tray package and etc.

While equipped a vertical form fill seal packing machine to automatically form the pillow type individual bags via film tube(bag former), weigher fills the bags with the noodles then packing machine seal and pack. While equip with a rotary packaging machine, packing machine pick up, open, fill and seal premade pouches in a high efficiency way.

Another method is to pack the trays with the noodles using a tray packing line. To cut costs, you can also select a semi-automatic weighing and filling line.

The instant noodles packaging machine is suitable for weighing and packaging long, thin, soft food products like konjac vermicelli, bean sprouts, potato vermicelli, udon noodles, etc.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved