Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Meet our Automatic Freeze-Dried Pet Food Packaging Machine, rotary pouch system designed to fill, nitrogen-flush, seal, inspect, and discharge premade pouches with freeze-dried pet food—all in one streamlined process.

SEND INQUIRY NOW

Meet our Automatic Freeze-Dried Pet Food Packaging Machine, a state-of-the-art rotary pouch system designed to fill, nitrogen-flush, seal, inspect, and discharge premade pouches with freeze-dried pet food—all in one streamlined process. This professional-grade packaging machine ensures your premium freeze-dried dog and cat foods are packed efficiently and safely, preserving freshness from your factory to the consumer's shelf. It's built for procurement managers and industry decision-makers seeking to improve packaging speed, consistency, and shelf life for pet food products. In the overview below, we detail the machine's functionality, technical specifications, benefits (from extended shelf life to automation and safety), compliance with industry standards, frequently asked questions, and how you can take the next step with this innovative solution.

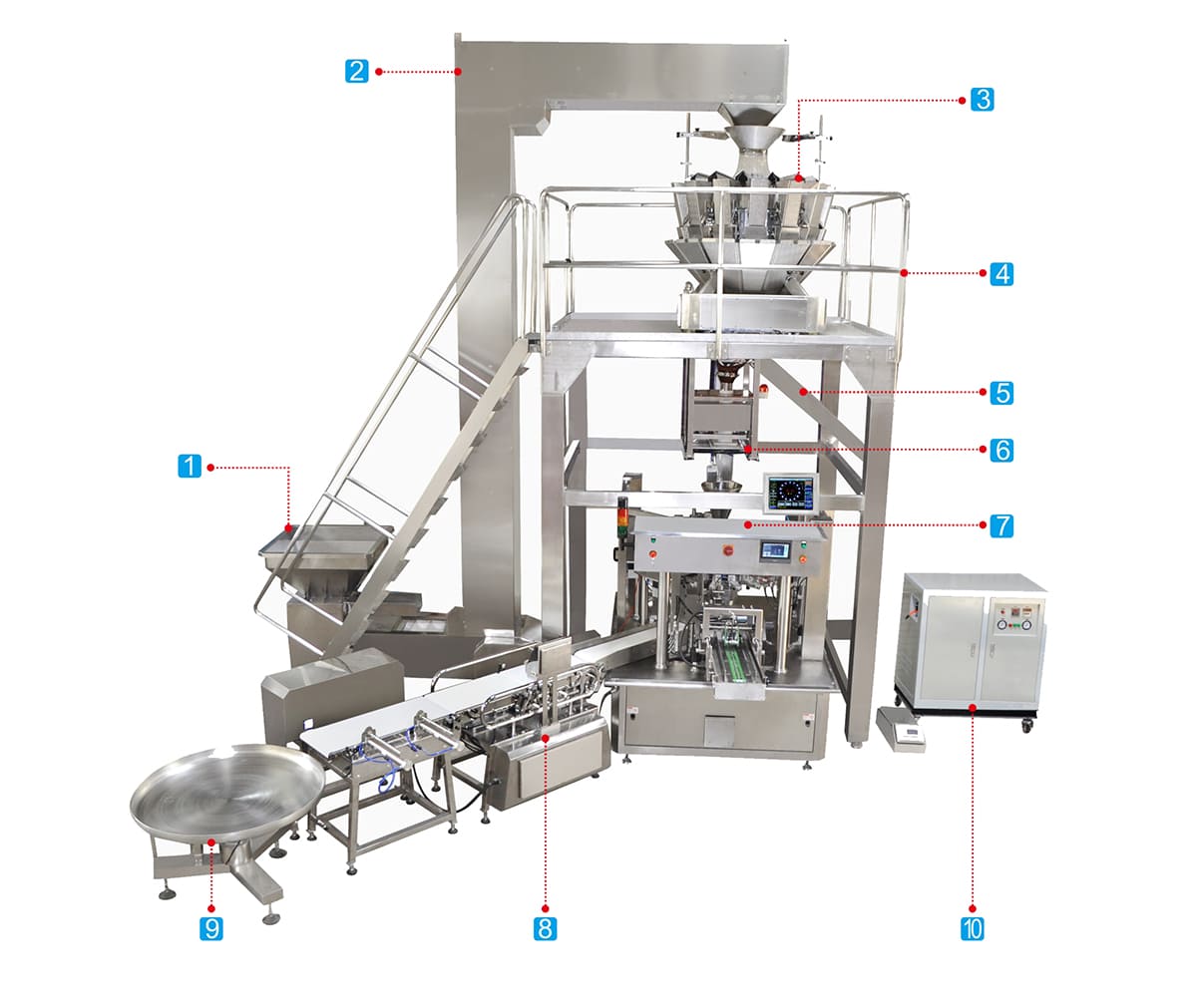

1 & 2. Feed Conveyor: Choose from a bucket or incline conveyor to automatically deliver pretzels into the weighing machine.

3. 14-Head Multihead Weigher: A commonly utilized, high-speed weighing solution offering exceptional accuracy.

4. Support Platform: Provides a stable, elevated structure to securely hold and support the machinery.

5 & 6. Throat Metal Detector and Reject Channel: Monitors product flow for metal contaminants and diverts any compromised product away from the main line.

7. Pouch Packing Machine: Efficiently fills and seals products into pouches, ensuring consistent packaging quality.

8. Checkweigher: Continuously verifies product weight to maintain quality standards and regulatory compliance.

9. Rotary Collection Table: Collects finished pouches, facilitating an organized transition to subsequent packaging steps.

10. Nitrogen Machine: Injects nitrogen into packages to preserve product freshness and extend shelf life.

Optional Add-ons

1. Date Coding Printer

Thermal Transfer Overprinter (TTO): Prints high-resolution text, logos, and barcodes.

Inkjet Printer: Suitable for variable data printing directly on packaging films.

2. Metal Detector

Integrated Detection: Inline metal detection to identify ferrous and non-ferrous metal contaminants.

Automatic Rejection Mechanism: Ensures contaminated packages are removed without halting production.

3. Secondary Wrapping Machine

Smartweigh's Wrapping Machine for Secondary Packaging is a high-efficiency solution designed for automatic bag folding and intelligent material management. It ensures precise, neat packaging with minimal manual intervention while optimizing material usage. Perfect for diverse industries, this machine seamlessly integrates into production lines, enhancing both productivity and packaging aesthetics.

| Weighing Range | 100 grams to 2000 grams |

|---|---|

| Number of Weighing Heads | 14 head |

| Packing Speed | 8 Station: 50 packs/min |

| Pouch Style | Premade pouch, flat pouches, zipper pouch, stand up bags |

| Pouch Size Range | Width: 100 mm - 250 mm Length: 150 mm – 350 mm |

| Power Supply | 220 V, 50/60 Hz, 3 kW |

| Control System | Multihead weigher: modular board control system with 7-inch touch screen Packing machine: PLC with 7-inch color touch-screen interface |

| Language Support | Multilingual (English, Spanish, Chinese, Korea, etc.) |

This automatic rotary premade pouch packaging system features multiple stations arranged in a circular layout. Freeze-dried pet food packaging is handled seamlessly through each stage of the process:

1. Pouch Loading & Opening: Pre-made pouches (such as stand-up bags or flat pouches) are loaded into a magazine hopper. A robotic arm or vacuum suction picks up each pouch and places it into the rotary indexing carousel. At the first stations, the pouch is securely gripped and opened—mechanical grips and air jets (or vacuum) ensure the pouch is fully open for filling. For pouches with resealable zippers, a device can pre-open the zipper to allow unobstructed filling.

2. Filling with Freeze-Dried Pet Food: Once the pouch is open, a precise dosing system fills it with the freeze-dried pet food product. This machine can integrate various fillers, such as a multi-head weigher for chunky freeze-dried pieces or an auger filler for powdery blends. High-accuracy scales drop the exact amount of product into each pouch, ensuring consistent weight with minimal variation (typically to within ±1 gram accuracy). The gentle fill process preserves the shape and integrity of delicate freeze-dried kibble or treats.

3. Nitrogen Flushing (Optional): Before sealing, the machine injects food-grade nitrogen gas into the pouch (a process called modified atmosphere packaging, or MAP). This nitrogen flush displaces oxygen inside the package, which is critical for freeze-dried foods. By pushing out oxygen to low residual levels (often under 3% O₂), the machine greatly reduces oxidation, moisture absorption, and microbial growth. The result is an extended shelf life and preserved nutrients for the pet food, since freeze-dried foods must be in airtight packages to prevent spoilage. (Nitrogen is an inert, safe gas comprising 78% of air, so it won't affect the food's taste or safety while it keeps it fresh.)

4. Inspection & Quality Checks: As pouches move through the stages, the machine employs built-in sensors and inspection systems. It verifies that each pouch is present, correctly opened, and properly filled before sealing. Standard safeguards include a "no pouch, no fill" and "no pouch, no seal" mechanism, so product is never dispensed if a pouch isn't in place or open. This prevents spills and avoids wasting product or creating messes.

5. Sealing the Pouch: With the pouch filled and flushed, the next station heat-seals the top of the pouch. Heat seal jaws press the pouch material together, melting the inner layers to form a strong, airtight seal. This creates a hermetic seal that locks out air and moisture, vital because freeze-dried pet foods rely on airtight pouches to maintain their quality. Our machine's sealing system is carefully calibrated for consistent temperature, pressure, and dwell time, so each bag gets a perfect seal. (For added seal integrity, some models have two sealing stages: a primary seal and a secondary cooling or crimp seal.)

6. Discharge: The final station releases the finished pouches onto an output conveyor. The sealed, nitrogen-flushed pet food pouches emerge neatly and are ready for case packing or further downstream handling. The end result is a line of uniform, pillow or stand-up pouches filled with premium freeze-dried pet food, each package reliably sealed for maximum freshness and shelf life.

Throughout this rotary workflow, the machine's intermittent motion indexing ensures each pouch stops at exactly the right position for each operation. The overall process is fully automated and continuous – as one pouch is being filled, another is being sealed, another is being discharged, and so on – optimizing throughput. An intuitive touchscreen HMI (Human-Machine Interface) allows operators to monitor the process in real time, showing station statuses, fill weights, and any fault alarms in clear text. In short, from loading empty pouches to outputting sealed products, the entire packaging cycle is handled with precision and minimal human intervention.

Our multihead weigher is engineered for exceptional accuracy and speed:

High-Precision Load Cells: Each head is equipped with sensitive load cells to ensure precise weight measurements, reducing product giveaway.

Flexible Weighing Options: Adjustable parameters to accommodate various jerky sizes and shapes.

Optimized Speed: Efficiently handles high-speed operations without compromising on accuracy, enhancing productivity.

Designed for premade pouches of almost any style. It works with flat 3- or 4-side sealed pouches, stand-up pouches (doypacks), premade gusseted bags, and pouches with or without resealable zipper closures. Whether your pet food is sold in a simple flat pouch or a premium stand-up pouch with a zipper and tear notch, this machine can fill and seal it. (It can even handle special formats like spouted pouches for liquids, though freeze-dried products typically use non-spouted bags.)

High-Speed Operation

Integrated System Design: Synchronization between the multihead weigher and packing machine enables smooth and rapid packaging cycles.

Enhanced Throughput: Capable of packaging up to 50 bags per minute, depending on product characteristics and packaging specifications.

Continuous Operation: Designed for 24/7 operation with minimal maintenance interruptions.

Gentle Product Handling

Minimal Drop Height: Reduces the distance biltong fall during packaging, minimizing breakage and maintaining product integrity.

Controlled Feeding Mechanism: Ensures a steady flow of freeze-dried pet food into the weighing system without clogging or spillage.

User-Friendly Interface

Touch-Screen Control Panel: Intuitive interface with easy navigation, allowing operators to monitor and adjust settings effortlessly.

Programmable Settings: Save multiple product parameters for quick changeovers between different packaging requirements.

Real-Time Monitoring: Displays operational data such as production speed, total output, and system diagnostics.

Durable Stainless Steel Construction

SUS304 Stainless Steel: Crafted with high-quality, food-grade stainless steel for durability and compliance with hygiene standards.

Robust Build Quality: Designed to withstand rigorous industrial environments, reducing long-term maintenance costs.

Easy Maintenance and Cleaning

Hygienic Design: Smooth surfaces and rounded edges prevent residue buildup, facilitating quick and thorough cleaning.

Tool-Free Disassembly: Key components can be disassembled without tools, streamlining maintenance procedures.

Compliance with Food Safety Standards

Certifications: Meets international standards such as CE, ensuring compliance and facilitating global market access.

Quality Control: Rigorous testing protocols ensure each machine meets our strict quality benchmarks before delivery.

1. Comprehensive Support

Consultation Services: Expert advice on selecting the right equipment and configurations.

Installation and Commissioning: Professional setup to ensure optimal performance from day one.

Operator Training: In-depth training programs for your team on machine operation and maintenance.

2. Quality Assurance

Stringent Testing Procedures: Each machine undergoes thorough testing to meet our high-quality standards.

Warranty Coverage: We offer warranties that cover parts and labor, providing peace of mind.

3. Competitive Pricing

Transparent Pricing Models: No hidden costs, with detailed quotations provided upfront.

Financing Options: Flexible payment terms and financing plans to accommodate budgetary constraints.

4. Innovation and Development

Research-Driven Solutions: Continuous investment in R&D to introduce cutting-edge features and enhancements.

Customer-Centric Approach: We listen to your feedback to improve our products and services continually.

Ready to take your freeze-dried pet food packaging to the next level? Contact Smart Weigh today for a personalized consultation. Our team of experts is eager to help you find the perfect packaging solution tailored to your business needs.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Get Free Quotation Now!

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved