Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost.

How can the weighing and tray packing of fast food be resolved?

To handle the issue of weighing, tray packing, and sealing huge amounts of ready-to-eat food, a German customer needed a packing solution.

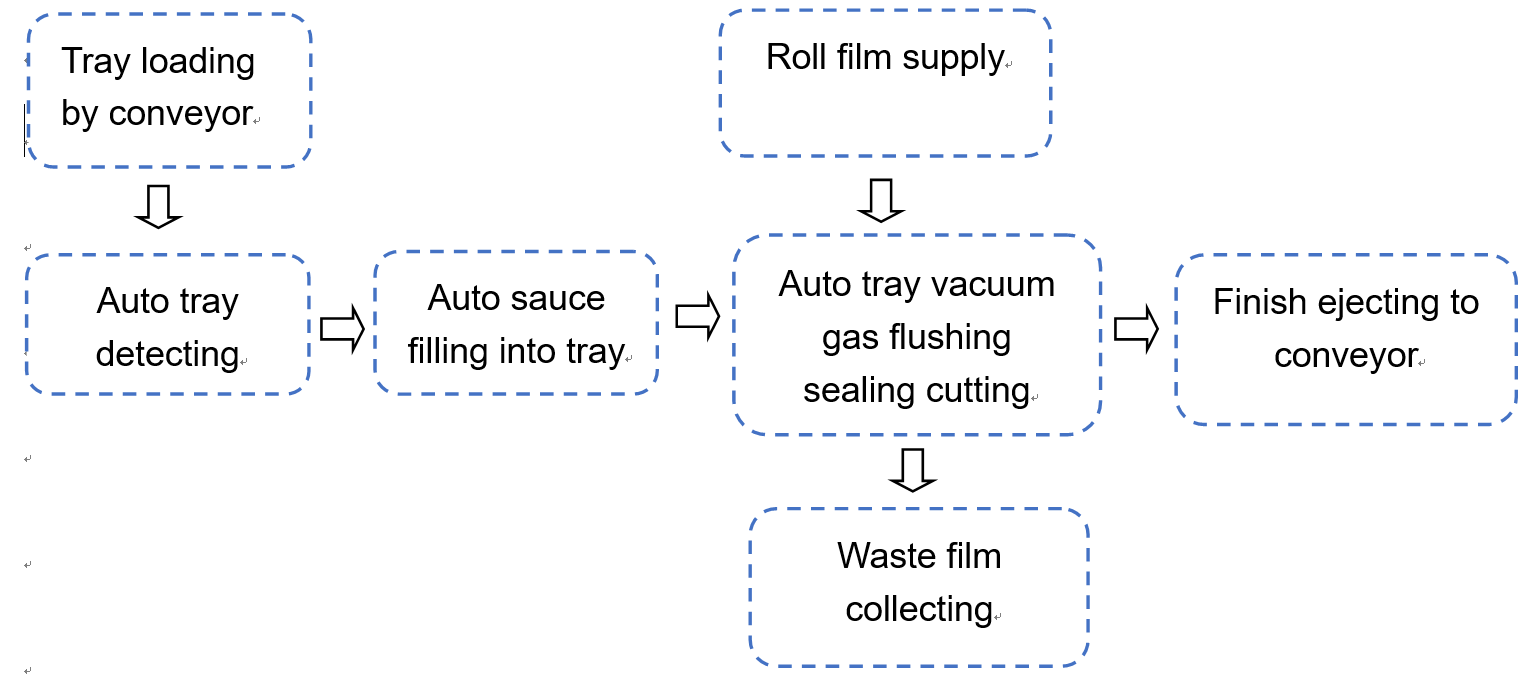

Smart Weigh provided an automatic linear tray packing system with tray supply, tray dispensing, automatic weighing, dosing, filling, vacuum gas flushing, sealing, and finished product output.

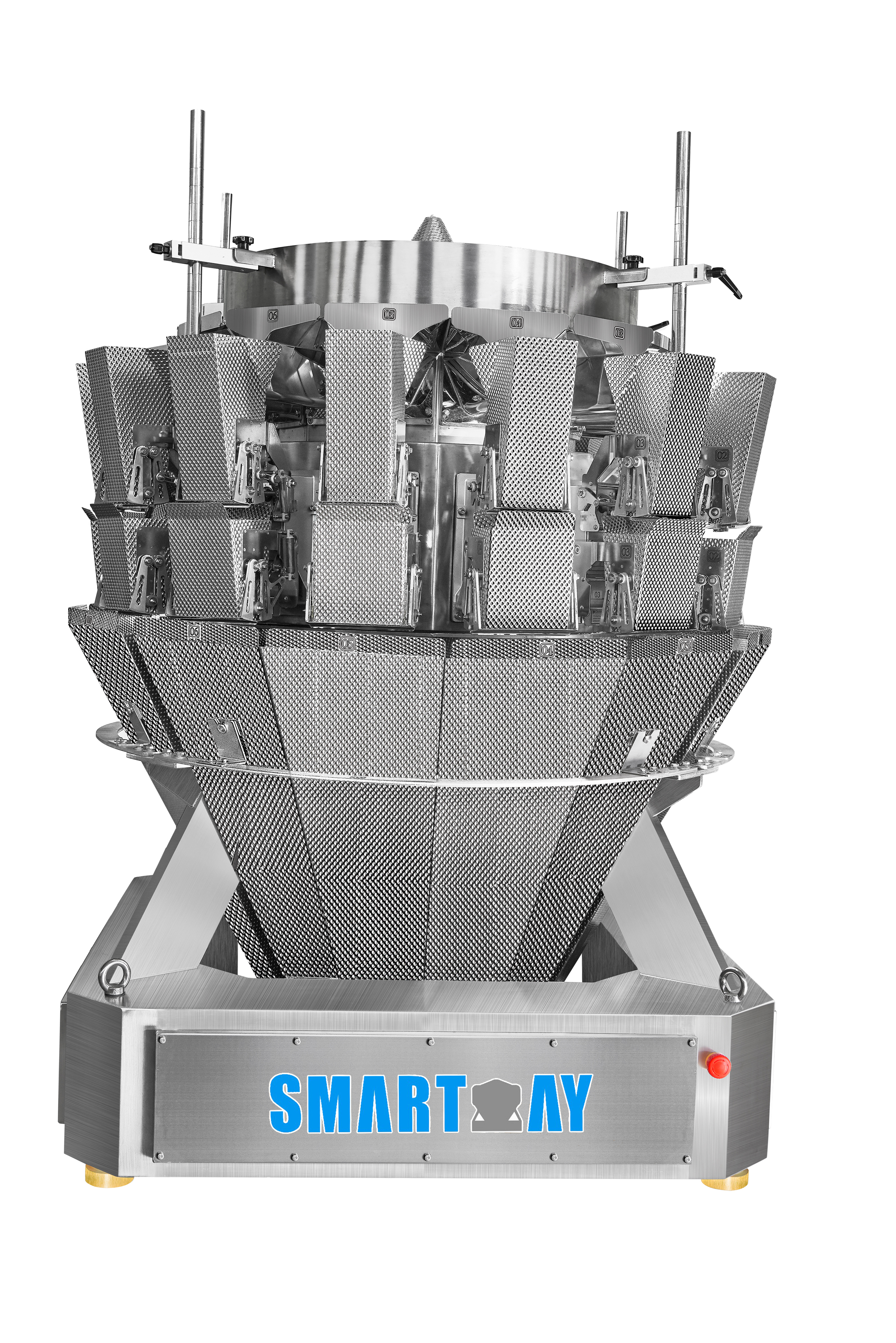

It can pack 1000–1500 fast food lunch boxes in one hour, which is highly effective and frequently used in canteens, restaurants, and food processing facilities.

Model | SW-2R-VG | SW-4R-VG |

Voltage | 3P380v/50hz | |

Power | 3.2kW | 5.5kW |

Sealing temperature | 0-300℃ | |

Tray size | L:W≤ 240*150mm H≤55mm | |

Sealing Material | PET/PE, PP, Aluminum foil, Paper/PET/PE | |

Capacity | 700 trays/h | 1400 trays/h |

Replacement rate | ≥95% | |

Intake pressure | 0.6-0.8Mpa | |

G.W | 680kg | 960kg |

Dimensions | 2200×1000×1800mm | 2800×1300×1800mm |

1. Servo motor that controls quick conveyor movement is low noise, smooth, and reliable. Positioning the trays accurately will lead to more accurate discharge.

2. Open tray dispenser with adjustable height for loading trays of various sizes and shapes. The tray can be placed into the mold using vacuum suction cups. Spiral separating and pressing, which prevents the pallet from being crushed, deformed, and damaged.

3. Photoelectric sensor can detect empty tray or no tray, can avoid sealing empty tray, material waste, etc.

4. Highly accurate multi-head weighing machine for precise material filling. The hopper with a patterned surface can be chosen for products that are oily and sticky. One person can easily modify the necessary weighing parameters using a touch screen.

5. To increase productivity when using automatic filling, consider one part two splicing, one part four splicing, and other feeding system.

6. The vacuum gas flushing method is significantly superior than the traditional gas flushing method because it ensures the purity of the gas, saves the gas source and can be used to lengthen the shelf life of food. It is equipped with a vacuum pump, vacuum valve, gas valve, bleeder valve, regulator, and other equipment.

7. Provide roll film; pull film with a servo. Rolls of film are located precisely, without deviation or misalignment, and the edges of the tray are firmly sealed with heat. A temperature control system can more effectively guarantee sealing quality. Reduce waste by gathering used film.

8. The automatic output conveyor transports the loaded trays to the platform.

SUS304 stainless steel and an IP65 waterproof system make for simple clean and maintain.

With a lengthy service life, it can adapt to a damp and greasy environment.

The machine body is resistant to deterioration thanks to the use of high-quality electrical and pneumatic components, ensuring dependable operation over an extended period of time.

Automation control system: it make up by PLC, Touch screen, servo system, sensor, magnetic valve, relays etc.

Pneumatic system: it make up by valve, air filter, meter, pressing sensor, magnetic valve, air cylinders, silencer etc.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425