Why Choose Smart Weigh's Pouch Packing Machine?

Smart Weigh offers comprehensive weighing packing lines for pouch packaging with multiple machine models designed to meet diverse production requirements. Our solutions include rotary pouch packing machines, horizontal pouch packing machines, vacuum pouch packing machines, and twin 8-station pouch packing machines, each engineered for specific manufacturing environments and product characteristics.

Smart Weigh Machine Models Overview

Available Machine Types:

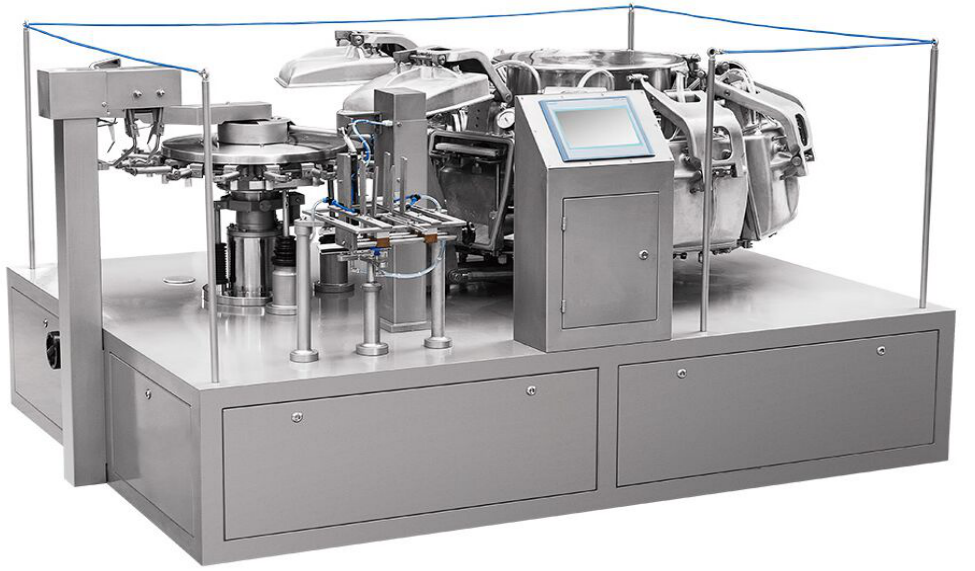

● Rotary Pouch Packing Machine: High-speed circular design for maximum throughput with continuous motion technology

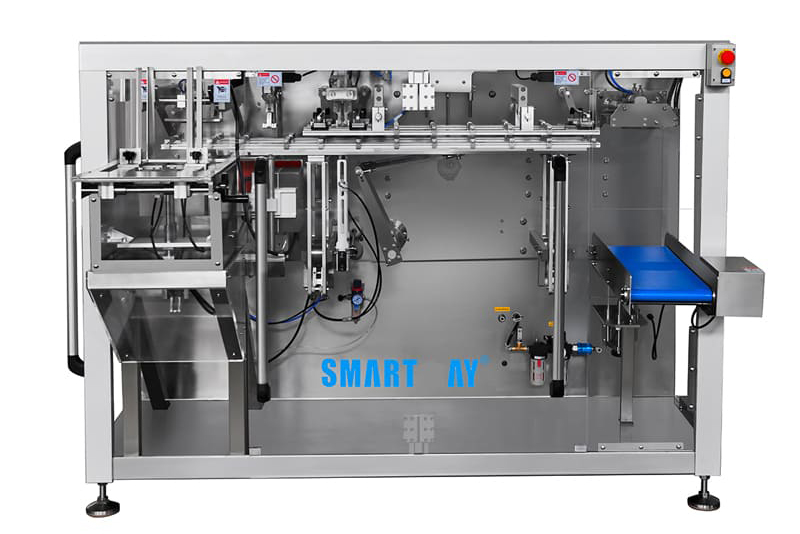

● Horizontal Pouch Packing Machine: Space-efficient with superior accessibility and enhanced bag storage capacity

● Vacuum Pouch Packing Machine: Extended shelf life with air removal technology and modified atmosphere packaging capability

● Twin 8-Station Pouch Packing Machine: Double capacity for large-scale operations with synchronized dual-line processing

Detailed Technical Specifications

Control System Features:

◇ 7-inch color HMI touch screen interface with multilingual support

◇ Advanced Siemens or Mitsubishi PLC control system

◇ Automatic bag width adjustment with servo motor precision

◇ Real-time production monitoring with data logging capability

◇ Parameter adjustment via touchscreen with recipe storage

◇ Remote monitoring capability with Ethernet connectivity

◇ Error diagnostic system with troubleshooting guidance

◇ Production statistics tracking and reporting functions

Safety Features:

◇ Interlock safety door switches (TEND or Pizz brand options)

◇ Automatic machine stop when doors open during operation

◇ HMI alarm indicators with detailed error descriptions

◇ Manual reset requirement for restart after safety events

◇ Abnormal air pressure monitoring with automatic shutdown

◇ Heater disconnection alarms for thermal protection

◇ Emergency stop buttons positioned at strategic locations

◇ Light curtain safety systems for operator protection

◇ Lockout/tagout compliance features for maintenance safety

Production Capabilities:

◇ Bag capacity: Up to 200 bags per loading cycle with automatic refill detection

◇ Changeover time: Reduced from 30 minutes to under 5 minutes with tool-free adjustments

◇ Waste reduction: Up to 15% compared to conventional systems through intelligent sensors

◇ Seal width: Up to 15mm with radian-angle design for superior strength

◇ Filling accuracy: ±0.5g precision with intelligent sensor feedback

◇ Speed range: 30-80 bags per minute depending on model and product type

◇ Bag size range: Width 100-300mm, length 100-450mm with quick-change capability

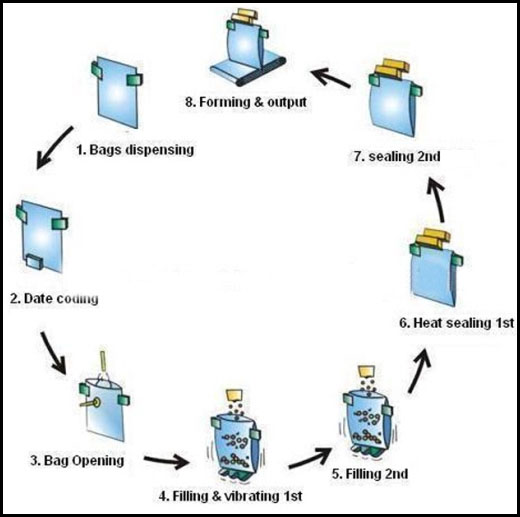

Comprehensive 8-Station Process Breakdown

Station Functions and Technical Details:

1. Bag Pickup Station: Sensor-controlled with 200-bag capacity magazine, automatic low-bag detection, and adjustable pickup pressure

2. Zipper Opening Station: Optional cylinder or servo control with success rate monitoring and jam detection

3. Bag Opening Station: Dual opening system (mouth and bottom) with air blower assistance and opening verification sensors

4. Filling Station: Intelligent sensor control with stagger dump feature, anti-spillage protection, and weight verification

5. Nitrogen Filling Station: Gas injection for preservation with flow rate control and purity monitoring

6. Heat Sealing Station: Primary seal application with temperature control and pressure monitoring

7. Cold Sealing Station: Secondary reinforcement seal with cooling system for immediate handling

8. Outfeed Station: Conveyor discharge to downstream equipment with reject system for defective packages

Benefits by Machine Type

Rotary Pouch Packing Machine Advantages:

◆ Continuous operation up to 50 bags per minute

◆ Ideal for free-flowing products like nuts, snacks, and granules

◆ Consistent packaging cycles with minimal vibration

◆ Easy maintenance access through removable panels

◆ Smooth product transfer between stations

◆ Reduced wear and tear through balanced rotation

Horizontal Pouch Packing Machine Advantages:

◆ Enhanced bag storage capacity with gravity-fed magazine system

◆ Superior operator accessibility for cleaning and maintenance

◆ Space-efficient layout suitable for low-ceiling facilities

◆ Easy integration with existing production lines

◆ Excellent for delicate products requiring gentle handling

◆ Quick-change tooling for multiple bag sizes

◆ Improved ergonomics for operator comfort

Vacuum Pouch Packing Machine Advantages:

◆ Extended product shelf life through oxygen removal

◆ Premium package presentation with professional appearance

◆ Oxygen removal capability down to 2% residual oxygen

◆ Enhanced product freshness preservation

◆ Reduced package volume for shipping efficiency

◆ Compatible with modified atmosphere packaging (MAP)

Twin 8-Station Machine Advantages:

◆ Double production capacity with single operator control

◆ Compact footprint design saving 30% floor space

◆ Maximum throughput efficiency, max 100 packs/min

◆ Reduced per-unit packaging costs through economies of scale

◆ Shared utility connections reducing installation costs

Advanced Technical Features

Intelligent Control Systems:

◇ Pouch Packing Machine Automatic Detection: No pouch, open error, no fill, no seal detection with statistical reporting

◇ Material Saving: Reusable bag system prevents waste with automatic sorting

◇ Weigher Stagger Dump: Coordinated filling prevents product waste through precise timing

◇ Air Blower System: Complete bag opening without overflow using calibrated air pressure

◇ Recipe Management: Store up to 99 different product recipes with quick changeover

Superior Construction Quality:

◇ Stainless steel food-contact surfaces with 304 grade for corrosive products

◇ IP65-rated electrical enclosures for washdown environments

◇ Food-grade material compatibility meeting FDA and EU regulations

◇ Easy-clean design features with minimal crevices and smooth surfaces

◇ Corrosion-resistant fasteners and components

◇ Tool-free disassembly for thorough cleaning

Integration Capabilities and Compatibility

Compatible Upstream Equipment:

Weighing Systems: Multihead weighers (10-24 head configurations), combination scales, linear weighers

Filling Systems: Auger fillers for powders, liquid pumps for sauces, volumetric fillers for granules

Feeding Systems: Vibratory feeders, belt conveyors, bucket elevators, pneumatic conveying

Preparation Equipment: Metal detectors, checkweighers, product inspection systems

Compatible Downstream Equipment:

Quality Control: Checkweighers, metal detectors, vision inspection systems

Handling Systems: Case packers, cartoners, palletizers, robotic handling

Conveyor Systems: Modular belt conveyors, incline conveyors, accumulation tables

Detailed Application Examples

Food Industry Applications:

Snack Foods: Nuts, chips, crackers, popcorn with oil-resistant sealing

Dried Products: Fruits, vegetables, jerky with moisture barrier protection

Beverages: Coffee beans, tea leaves, powdered drinks with aroma preservation

Condiments: Spices, seasonings, sauces with contamination prevention

Bakery Items: Cookies, crackers, bread with freshness retention

Non-Food Applications:

Pet Food: Treats, kibble, supplements with nutritional preservation

Pharmaceutical: Tablets, capsules, powders under clean room conditions

Chemical: Fertilizers, additives, samples with safety containment

Hardware: Small parts, fasteners, components with organization benefits

Frequently Asked Questions

Q: What products can Smart Weigh pouch packing machines handle?

A: Our machines package solids (nuts, snacks, granules), liquids (sauces, oils, dressings), and powders (spices, supplements, flour) with appropriate feeder systems. Each model accommodates specific product characteristics and flow properties.

Q: How does the automatic bag width adjustment work?

A: Input the bag width on the 7-inch touch screen, and servo motors automatically adjust jaw gaps, conveyor positions, and sealing parameters—no manual tools or adjustments required. The system stores settings for quick product changeovers.

Q: What makes Smart Weigh's sealing technology superior?

A: Our patented radian-angle dual sealing system (heat + cold) creates 15mm wide seals that are significantly stronger than traditional flat sealing methods. The two-stage process ensures package integrity even under stress.

Q: Can machines handle specialized pouch types?

A: Yes, our systems accommodate stand-up pouches, zipper pouches, spout pouches, and custom shapes. Station 2 provides optional zipper opening with cylinder or servo control for reliable resealable pouch processing.

Q: What safety features prevent workplace accidents?

A: Interlock door switches immediately stop operation when opened, with HMI alarms and manual reset requirements. Emergency stops, light curtains, and lockout/tagout capabilities ensure comprehensive operator protection.

Q: How do you minimize downtime during maintenance?

A: Quick-disconnect fittings, tool-free access panels, and predictive maintenance sensors reduce service time. Our modular design allows component replacement without complete line shutdown.

Machine Selection Guide

Choose Rotary Model For:

1. High-speed production requirements (60-80 bags/minute)

2. Limited floor space with vertical space available

3. Free-flowing products with consistent characteristics

4. Continuous operation requirements with minimal interruption

Choose Horizontal Model For:

1. Maximum bag storage needs with easy refilling

2. Easy maintenance access in constrained spaces

3. Flexible production scheduling with frequent changeovers

Choose Vacuum Model For:

1. Extended shelf life requirements for premium products

2. Premium product positioning with enhanced presentation

3. Oxygen-sensitive products requiring preservation

Choose Twin 8-Station For:

1. Maximum production capacity requirements (up to 160 bags/minute)

2. Large-scale operations with high volume demands

3. Multiple product lines requiring simultaneous processing

4. Cost-per-unit optimization through increased throughput

Conclusion

Smart Weigh's comprehensive pouch packing machine lineup provides tailored solutions for every production requirement, from small-batch specialty foods to high-volume commercial operations. Our complete weighing packing lines integrate seamlessly from product feeding to final discharge, ensuring optimal performance, reliability, and return on investment.

Key Competitive Advantages:

◇ Multiple machine models engineered for specific production needs

◇ Complete integrated line solutions reducing complexity and compatibility issues

◇ Advanced safety and control systems exceeding industry standards

◇ Proven operational improvements with measurable ROI

◇ Comprehensive technical support and global service network

◇ Continuous innovation and technology advancement

Contact Smart Weigh today to schedule a consultation with our packaging experts. We'll analyze your specific pouch packaging requirements and recommend the optimal machine model and configuration for your production goals, ensuring maximum efficiency and profitability for your operation.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine