Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost.

How does a multhead weigher work?

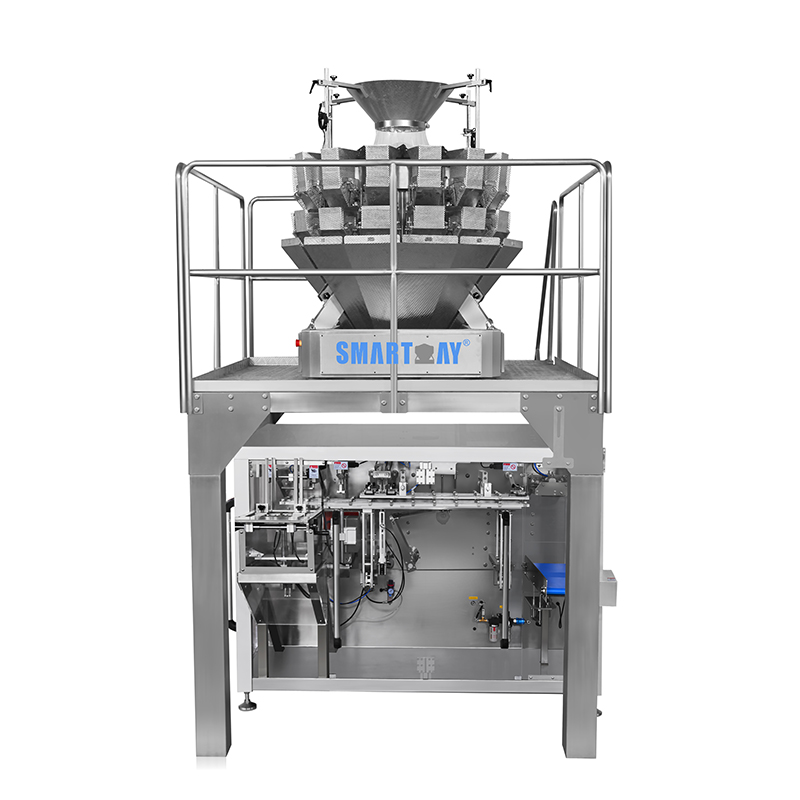

Technology has drastically advanced in this modern age and time, with multihead weighers being used in almost every line of business. They are the equipment standard for weighing applications in various industries mainly of their speed and accuracy.

Multihead weighers use various weigh beads to generate accurate measurements of the product by calculating the weight in each weigh head. Further on, each weigh head has its precision load, which contributes to the ease of the process. The real question is how to multihead weighers calculate combinations in this process?

The process starts with the product being fed into the top of the multihead weigher. It is distributed onto a set of linear feed plates by a dispersal system, usually a vibrating or spinning top cone. A load cell is generally installed on the entire cone, which controls the product input to the multihead weigher.

The product is equally portioned and distributed on the conical funnel to the linear feed pan after falling through the raise into the bucket of the combination weigher, vibrating into the main feeder. When the product finishes in the bucket, it is automatically detected by the horizontal photo detector that immediately sends a signal to the Mainboard and a final signal to the conveyor. A series of curtains were placed around the linear feeders to ensure accuracy and equal distribution of the product to the feed hopper. To your advantage, you can easily control the amp's location and duration of the vibration depending on the characteristics of your product. For example, if you deal with adhesive products, vibrations may be required, whereas minimal vibration is necessary for free-flowing products to get them moving.

After this process occurs, the material generates a weight signal through the sensor and then transmits it to the motherboard of control equipment through the lead wire. The Main action happens during calculations, where the CPU on the motherboard reads and records the eight of each weighing bucket for accuracy and precision. It then selects the combination weighing bucket closest to the target weight through data analysis. The linear feeder is bound to deliver some product into a feed hopper. For instance, in a 20-head multihead weigher, there will be 20 linear feeders delivering 20 Products to feed hoppers. After this process, the feed hoppers empty their contents into the weigh hoppers before starting again. The processor in the multihead weigher then calculates the best combination of weights required to achieve the desired target weight. Further on, after all the calculations take place, the weighted proportions fall into the bagging system or product trays.

After receiving the final signal for release from the packaging machine, the CPU will issue a command to start the driver to open the hopper to unload the product to the packaging machine and send a packaging signal to the machine.

Smart Weigh Packaging Machinery Co., Ltd is a designer and manufacturer for multihead weigher, linear weigher and combination weigher. We provide a range of weighing solutions to meet the needs of different customers.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425