Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

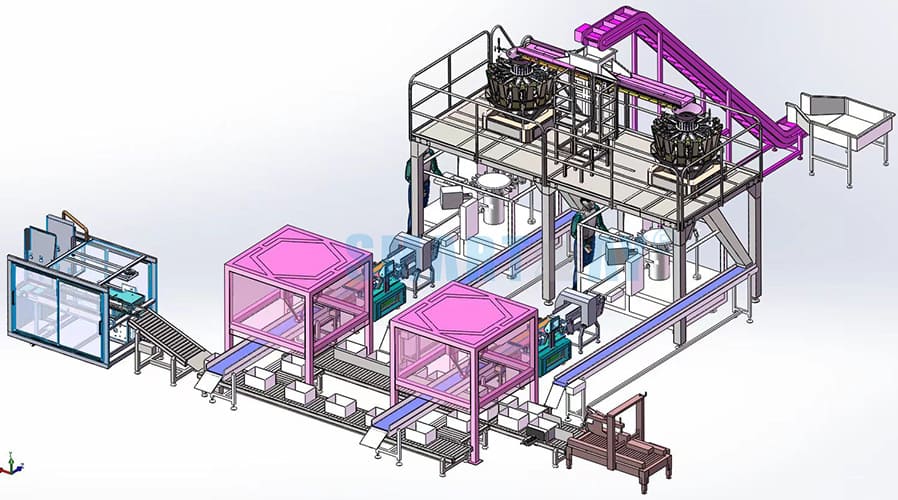

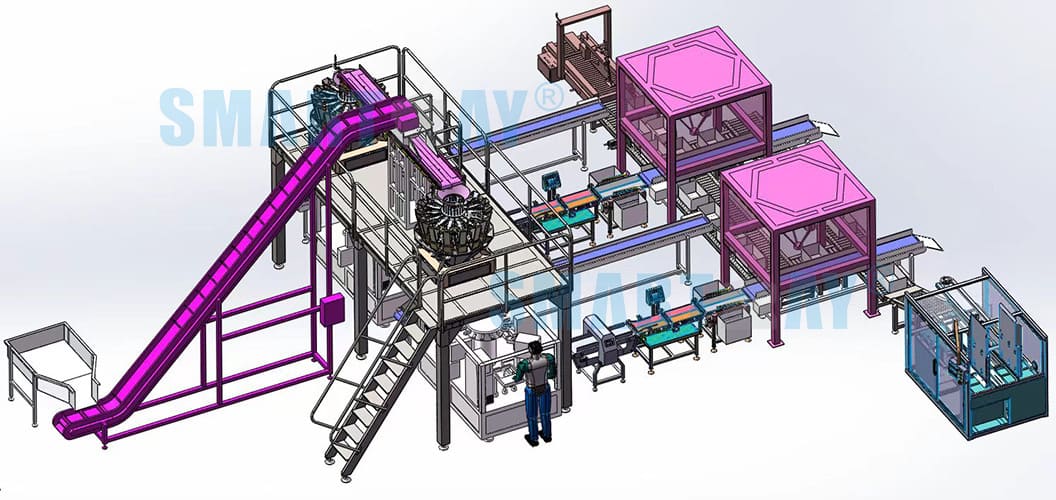

Efficiency, and automation play pivotal roles in ensuring product safety, maximizing throughput, and minimizing labor costs in seafood industry. A notable example from Smart Weigh of such innovation is found in the shrimp packaging system, a state-of-the-art solution designed for precision, speed, and reliability. This case study delves into the intricacies of this system, showcasing its components, performance metrics, and the seamless integration of automation in every step of the packaging process.

The shrimp packaging system is a comprehensive solution engineered to address the challenges of handling frozen seafood, such as shrimp, in a way that maintains product integrity while optimizing the packaging workflow and extend the product shelf life. Each machine is designed to perform with high efficiency and accuracy, contributing to the overall performance of the system.

* Rotary Pouch Packaging Machine: Capable of producing 40 packs per minute, this machine is a powerhouse of efficiency. It is specifically designed to handle the delicate process of filling pouches with shrimp, ensuring that each pouch is perfectly portioned and sealed without compromising the product's quality.

* Carton Packing Machine: Operating at a speed of 25 cartons per minute, this machine automates the process of preparing cartons for the final packaging phase. Its role is crucial in maintaining the pace of the packaging line, ensuring that there's a consistent supply of ready-to-fill cartons.

The shrimp packaging system is a marvel of automation, comprising several stages that form a cohesive and streamlined process:

1. Auto Feeding: The journey begins with the automated feeding of shrimp into the system, where they are transported to the weighing station in preparation for packaging.

2. Weighing: Precision is key in this stage, as each portion of shrimp is carefully weighed to ensure that the contents of each pouch are consistent, meeting predefined quality standards.

3. Pouch Opening: Once the shrimp are weighed, the system automatically opens each pouch, preparing it for filling.

4. Pouch Filling: The weighed shrimp are then filled into the pouches, a process that is carefully controlled to prevent damage to the product and ensure uniformity across all packages.

5. Pouch Sealing: After filling, the pouches are sealed, securing the shrimp within and preserving their freshness.

6. Metal Detecting: As a measure of quality control, the sealed pouches pass through a metal detector to ensure that there are no contaminants present.

7. Opening Cartons from Cardboard: Parallel to the pouch handling process, the carton opening machine transforms flat cardboard into ready-to-fill cartons.

8. Parallel Robot Picks Finished Bags into Cartons: A sophisticated parallel robot then picks the finished, sealed pouches and places them into the cartons, demonstrating precision and efficiency.

9. Close and Tape Cartons: Finally, the filled cartons are closed and taped, rendering them ready for shipment.

The shrimp packaging system represents a significant leap forward in frozen food packaging technologies. By integrating advanced automation and precision seafood packaging machines, they offers an efficient, reliable, and scalable solution to the challenges of shrimp packaging. This system not only enhances productivity but also ensures that the quality of the packaged product meets the highest standards, ultimately benefiting both producers and consumers alike. Through such innovations, the food packaging industry continues to evolve, setting new benchmarks for performance and automation.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved