Hagaha Dhammaystiran ee Mashiinka Baakadaha ee Baakadaha

Annagoo ah soo saaraha hormuudka ka ah mashiinka baakadaha bacaha ee ka yimid Shiinaha, waxaan inta badan la kulannaa su'aalo ku saabsan noocyada, shaqooyinka, iyo agabka loo isticmaalo mashiinnadan macaamiisha. Maxaa ka dhigaya mashiinnada baakadaha bacaha kuwo aad muhiim u ah warshadaha baakadaha maanta? Sidee bay ganacsiyadu uga faa'iideysan karaan hufnaanta iyo waaritaanka?

Mashiinnada baakadaha ee bacaha ayaa wax ka beddelaya habka loo xirxiro badeecadaha, iyagoo bixinaya dabacsanaan, saxnaan, iyo habayn. Waxay u adeegaan warshado kala duwan, oo ay ku jiraan cuntada, daawooyinka, iyo qurxinta, iyagoo bixinaya xalal loogu talagalay baahiyaha baakadaha kala duwan.

Fahmidda mashiinnadani waa mid muhiim u ah ganacsiyada doonaya inay maalgashadaan xalalka baakadaha casriga ah. Aan u fiirsanno hagaha dhammaystiran ee mashiinnada baakadaha lagu xidho.

Waa maxay faa'iidooyinka Mashiinka Baakadaha ee Boorsada?

Mashiinnada baakadaha ee bacaha waxay bixiyaan faa'iidooyin badan, sida hufnaan la xoojiyay, qashin yar, iyo ilaalinta badeecada. Sidee faa'iidooyinkani ugu beddelaan codsiyo dhab ah?

Waxtarka La Kordhiyay : Mashiinnada bacaha otomaatiga ah waxay otomaatigeeyaan hawlaha daalka badan, iyagoo badbaadinaya waqtiga iyo kharashka shaqada. Sida laga soo xigtay jawaab celinta macaamiisha, otomaatiga waxay hagaajin kartaa hufnaanta ilaa 40%.

Qashin Yar : Xakamaynta otomaatiga ah waxay yareysaa kharashka qashinka alaabta iyo baakadaha alaabta. Jawaab celinta macaamiisheenna Cilmi-baaris ayaa muujinaysa in otomaatiga ay yareyn karto qashinka 30%.

Kharash yar oo shaqo : Khadadka buuxinta ee nus-otomaatigga ah waxay ka caawiyaan macaamiisha inay badbaadiyaan ugu yaraan 30% shaqo, nidaamka mashiinka baakadaha oo si buuxda otomaatig ah u shaqeeya wuxuu badbaadiyaa 80% shaqo marka la barbar dhigo miisaanka iyo baakadaha gacanta ee dhaqameed.

Ilaalinta Badeecada: Mashiinnada la habeyn karo waxay hubiyaan badbaadada badeecada waxayna yareeyaan khataraha wasakhowga.

Noocyada Mashiinnada Baakadaha ee Boorsada ah ee la heli karo?

Mashiinnada baakadaha ee bacaha waxaa loo kala saaraa Mashiinnada baakadaha ee la sameeyay, Mashiinnada buuxinta foomka toosan (VFFS) iyo Mashiinnada buuxinta foomka toosan (HFFS). Maxaa kala soocaya noocyadan?

Mashiinka Shaabadda Buuxinta Foomka Toosan

Mashiinka Baakadaha ee Hore loo Sameeyay : Loogu talagalay in lagu buuxiyo bacaha diyaarsan oo leh alaabooyin kala duwan, sida bacaha fidsan ee hore loo sameeyay, bacaha taagan, bacaha doy ee sibidhka leh, bacaha gusseted dhinaca, 8 bacaha shaabadda dhinaca iyo bacaha biqilka.

Mashiinnada Shaabadda Buuxinta Foomka Toosan : Ku habboon labadaba xawaaraha wax soo saarka yar iyo kan sare, mashiinnadani waxay ka sameeyaan bacaha duubka filimka. Mashiinnada shaabadda buuxinta qaabka toosan ee xawaaraha sare leh ayaa loo doorbidaa cuntooyinka fudud ee hawlgallada ballaaran. Marka laga soo tago bacaha barkimooyinka qaabka caadiga ah iyo bacaha gusseted, mashiinka baakadaha toosan wuxuu sidoo kale samayn karaa bacaha afar-shaabadaysan, bacaha hoose ee fidsan, bacaha 3-dhinac iyo 4-dhinac ee shaabadda.

Mashiinnada HFFS: Noocan mashiinnada ah ayaa caadi ahaan looga isticmaalaa Yurub, sida vffs, hffs waxay ku habboon tahay alaabada adag, hal-shay, dareereyaasha, mashiinnadani waxay ku xidhaan alaabada meel fidsan, bacaha taagan ama habeeyaan bacaha qaab aan caadi ahayn.

Sidee bay u shaqeeyaan Mashiinka Baakadaha ee Boorsada Hore loo sameeyay?

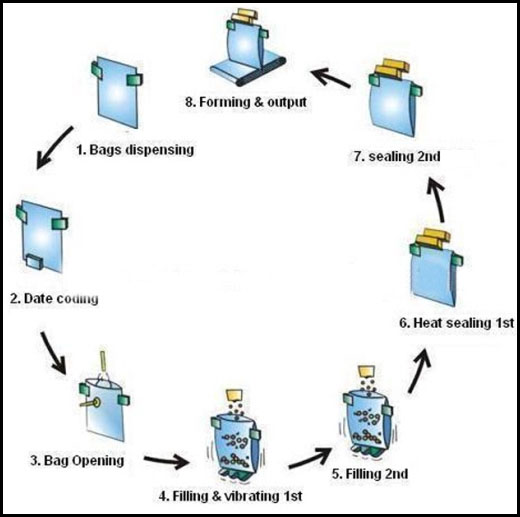

Mashiinka baakadaha ee hore loo sameeyay waa qalab baakado oo gaar ah oo loogu talagalay in lagu buuxiyo laguna xiro bacaha horey loo sameeyay. Si ka duwan mashiinnada Shaabadda Buuxinta Foomka Toosan (VFFS), kuwaas oo sameeya bacaha duubka filimka, bacaha gacanta ee mashiinka baakadaha ee hore loo sameeyay oo horey loo sameeyay oo diyaar u ah buuxinta. Waa kan sida mashiinka baakadaha ee hore loo sameeyay u shaqeeyo:

1. Boorsada oo la soo rarayo

Rarista Gacanta: Hawl-wadeennadu waxay gacanta ku ridi karaan bacaha hore loo sameeyay ee ku jira mashiinka.

Soo Qaadista Tooska ah: Mashiinnada qaar waxay leeyihiin nidaamyo quudin oo otomaatig ah oo soo qaada oo dhigta bacaha booska.

2. Ogaanshaha iyo Furitaanka Boorsada

Dareemayaasha: Mashiinku wuxuu ogaadaa joogitaanka bacda wuxuuna hubiyaa inay ku jirto booska saxda ah.

Habka Furitaanka: Qabanqaabiyeyaasha gaarka ah ama nidaamyada faakiyuumka ayaa fura bacda, iyagoo u diyaarinaya buuxinta.

3. Daabacaadda Taariikhda Ikhtiyaarka ah

Daabacaadda: Haddii loo baahdo, mashiinku wuxuu ku daabacan karaa macluumaad sida taariikhaha dhicitaanka, lambarrada dufcadda, ama faahfaahin kale oo ku yaal bacda. Saldhiggan, mashiinnada baakadaha ee bacda waxay ku qalabayn karaan daabacaha ribbon, daabacayaasha wareejinta kulaylka (TTO) iyo xitaa mashiinka codaynta laysarka.

4. Buuxinta

Bixinta Badeecada: Badeecada waxaa lagu shubaa bacda furan. Tan waxaa lagu samayn karaa iyadoo la adeegsanayo nidaamyo buuxin oo kala duwan, iyadoo ku xiran nooca badeecada (tusaale ahaan, dareere, budo, adag).

5. Qiimo-dhaca

Qalab khafiifiya hawada si looga saaro hawada xad-dhaafka ah ee ku jirta bacda ka hor inta aan la xidhin, iyadoo la hubinayo in waxa ku jira si adag loo xirxiray oo loo ilaaliyay. Habkani wuxuu yareeyaa mugga ku jira baakadda, taasoo horseedi karta isticmaalka hufan ee booska kaydinta iyo suurtogalnimada in la wanaajiyo cimriga shelf ee badeecada iyadoo la dhimayo soo-gaadhista oksijiinta, taas oo gacan ka geysan karta burburka ama burburka agabka qaarkood. Intaa waxaa dheer, iyadoo laga saarayo hawada xad-dhaafka ah, qalabka khafiifiya hawada wuxuu diyaariyaa bacda tallaabada xigta ee xidhitaanka, isagoo abuuraya jawi ku habboon shaabad ammaan ah oo joogto ah. Diyaarintani waa mid muhiim u ah ilaalinta hufnaanta baakadda, ka hortagga daadashada suurtagalka ah, iyo hubinta in badeecaddu ay ahaato mid cusub oo aan wasakhoobin inta lagu jiro rarista iyo kaydinta.

6. Shaabadaynta

Daannada shaabadeynta kulul ama habab kale oo shaabadeynta ah ayaa loo isticmaalaa in si ammaan ah loogu xiro bacda. Waa muhiim in la ogaado in naqshadda daannada shaabadeynta ee bacaha la dahaadhay iyo bacaha PE (Polyethylene) ay kala duwan yihiin, qaababkooda shaabadeyntuna way kala duwan yihiin. Bacaha la dahaadhay waxay u baahan karaan heerkul iyo cadaadis shaabadeyn gaar ah, halka bacaha PE ay u baahan karaan jawi ka duwan. Sidaa darteed, fahamka kala duwanaanshaha hababka shaabadeynta waa lama huraan, waana muhiim inaad hore u ogaato agabkaaga baakadda.

7. Qaboojinta

Bacda la shaabadeeyay waxay dhex mari kartaa goob qaboojin si loo dejiyo shaabadda, shaabadda bacda waa la qaboojiyaa si looga hortago isbeddelka heerkulka sare ee shaabadda inta lagu jiro hababka baakadaha ee xiga.

8. Ka bixitaan

Bacda la dhammeeyay ayaa ka dib laga saarayaa mashiinka, iyadoo gacanta lagu hayo qof hawl wadeen ah ama si toos ah loogu shubayo nidaamka gudbiyaha.

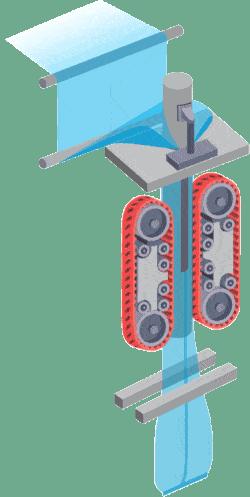

Sidee ayay u shaqeeyaan Mashiinnada Shaabadda Buuxinta Foomka Toosan?

Mashiinnada Shaabadda Buuxinta Foomka Toosan (VFFS) waa xulasho caan ah oo ka jirta warshadaha baakadaha sababtoo ah hufnaantooda iyo kala duwanaanshahooda. Waa kan sida mashiinka VFFS u shaqeeyo, oo loo qaybiyo marxalado muhiim ah:

Furitaanka Filimka : Filim duuban ayaa lagu shubaa mashiinka, waana la furfuraa marka uu socdo hawsha.

Nidaamka Jiidista Filimada : Filimka waxaa lagu jiidaa mashiinka iyadoo la adeegsanayo suun ama duubab, taasoo hubinaysa socod siman oo joogto ah.

Daabacaadda (Ikhtiyaar): Haddii loo baahdo, filimka waxaa lagu daabici karaa macluumaad sida taariikhaha, lambarrada, calaamadaha, ama naqshadaha kale iyadoo la adeegsanayo daabacayaasha kulaylka ama khadka.

Booska Filimka : Dareemayaashu waxay ogaadaan booska filimka, iyagoo hubinaya inuu si sax ah u toosan yahay. Haddii la ogaado wax khalad ah, waxaa la sameeyaa hagaajin si loogu beddelo booska filimka.

Samaynta Boorsada : Filimka waxaa lagu shubaa tuubo qaabaysan oo koon ah, taasoo u qaabaynaysa bac. Labada gees ee dibadda ee filimku way is dul saaran yihiin ama way is dul saaran yihiin, shaabad toosanna waa la sameeyaa si loo sameeyo tolmada dambe ee boorsada.

Buuxinta : Badeecada la xidhi doono waxaa lagu ridaa bacda la sameeyay. Qalabka buuxinta, sida miisaan madax badan leh ama buuxinta auger, wuxuu hubiyaa cabbirka saxda ah ee badeecada.

Shaabad Jiif ah : Daannada shaabadaysan ee kulul ayaa isku xira si ay u xidhaan dusha sare ee hal bac iyo hoosta xigta. Tani waxay abuurtaa shaabadda sare ee hal bac iyo shaabadda hoose ee kan xiga oo safan.

Jaritaanka Boorsada : Bacda la buuxiyay oo la shaabadeeyay ayaa markaa laga jarayaa filimka joogtada ah. Jaritaanka waxaa lagu samayn karaa daab ama kuleyl, iyadoo ku xiran mashiinka iyo agabka.

Gudbinta Bacaha Dhammaystiran : Bacaha dhammeysan ayaa markaa loo gudbiyaa marxaladda xigta, sida kormeerka, calaamadaynta, ama ku xidhitaanka kartoonada.

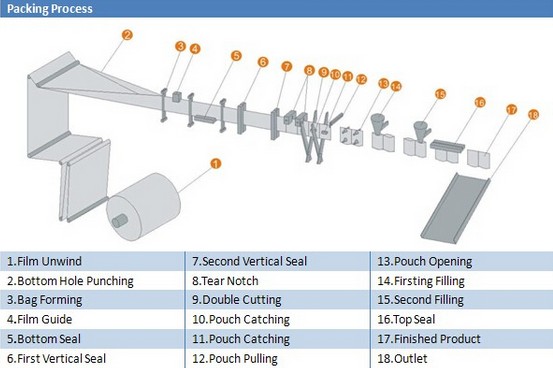

Sidee ayay u shaqeeyaan Mashiinnada Shaabadda Buuxinta Foomka Jiidaha ah?

Mashiinka Shaabadda Buuxinta Foomka Jiifka ah (HFFS) waa nooc ka mid ah qalabka baakadaha kaas oo sameeya, buuxiya, oo shaabadeeya alaabta qaab jiif ah. Waxay si gaar ah ugu habboon tahay alaabada adag ama si gaar ah loo qaybiyay, sida buskudka, nacnaca, ama aaladaha caafimaadka. Waa kan sharraxaad faahfaahsan oo ku saabsan sida mashiinka HFFS u shaqeeyo:

Gaadiidka Filimada

Furitaanka: Filim duuban ayaa lagu shubaa mashiinka, waxaana si siman loo furfuraa marka hawshu bilaabato.

Xakamaynta Xiisadda: Filimka waxaa lagu hayaa xiisad joogto ah si loo hubiyo dhaqdhaqaaq siman iyo sameynta saxda ah ee kiish.

Samaynta Boorsada

Samaynta: Filimku wuxuu u qaabaysan yahay bac iyadoo la adeegsanayo qaabab gaar ah ama qalab qaabayn. Qaabku wuu kala duwanaan karaa iyadoo lagu salaynayo shuruudaha badeecada iyo baakadaha.

Shaabadeynta: Dhinacyada bacda waa la shaabadeeyay, badanaa waxaa la isticmaalaa habab shaabadeyn kuleyl ama ultrasonic ah.

Meelaynta iyo Hagidda Filimka

Dareemayaasha: Kuwani waxay ogaadaan booska filimka, iyagoo hubinaya inuu si sax ah u toosan yahay si loo sameeyo kiish sax ah iyo shaabad.

Shaabad toosan

Cidhifyada toosan ee kiishka waa la shaabadeeyay, taasoo abuureysa tolmo dhinaca kiishka ah. Halkan ayay ka timid ereyga "shaabaddii toosan", inkastoo mashiinku si toosan u shaqeeyo.

Jaritaanka Kiishka

Ka jarista Filimka Joogtada ah iyo kala soocida bacaha shaqsiga ah iyo duub joogto ah oo filim ah.

Furitaanka Boorsada

Furitaanka Boorsada: Shaqada furitaanka boorsada waxay hubineysaa in boorsada si habboon loo furay oo ay diyaar u tahay in la helo badeecada.

Isku-dubaridka: Kiishka waa in si sax ah loo hagaajiyaa si loo hubiyo in habka furitaanka uu si wax ku ool ah u geli karo oo u furi karo kiishka.

Buuxinta

Bixinta Badeecada: Badeecada waxaa la dhigayaa ama lagu shubayaa bacda la sameeyay. Nooca nidaamka buuxinta ee la isticmaalay waxay ku xiran tahay badeecada (tusaale ahaan, buuxinta cufisjiidadka dareeraha, buuxinta mugga ee adkaha).

Buuxinta Marxalado Badan (Ikhtiyaar): Badeecadaha qaar waxay u baahan karaan marxalado ama qaybo badan oo buuxin ah.

Shaabadeynta Sare

Shaabadeynta: Dusha sare ee bacda waa la shaabadeeyay, taasoo hubinaysa in badeecaddu si ammaan ah u xiran tahay.

Jaritaan: Bacda la shaabadeeyay ayaa markaa laga soocaa filimka joogtada ah, iyadoo loo marayo daab jaritaan ama kuleyl.

Gudbinta Boorsada Dhammaystiran

Bacaha la dhammeeyay waxaa loo gudbiyaa marxaladda xigta, sida baaritaanka, calaamadaynta, ama ku xidhitaanka kartoonada.

Waa maxay Agabka loo isticmaalo Baakadaha Baakadaha?

Doorashada agabka ayaa muhiim u ah tayada iyo waaritaanka badeecadda. Waa maxay agabka caadiga ah ee loo isticmaalo baakadaha bacaha?

Filimada Balaastikada ah : Waxaa ku jira filimaan lakab badan leh iyo filimaan lakab keliya leh sida Polyethylene (PE), Polypropylene (PP), iyo Polyester (PET).

Aluminium Foil : Waxaa loo isticmaalaa ilaalinta caqabadaha oo dhan. Cilmi-baaristu waxay iftiiminaysaa adeegsigeeda.

Warqad : Ikhtiyaar baaba'aya oo loogu talagalay alaabta qalalan. Daraasaddani waxay ka hadlaysaa faa'iidooyinkeeda.

Xirmada dib-u-warshadaynta : baakad dib-u-warshadayn ah oo mono-pe ah

Nooca mashiinka miisaanka noocee ah ayaa la shaqayn kara mashiinka baakadaha bacaha?

Isku-darka mashiinnada miisaanka iyo nidaamyada baakadaha bacaha waa arrin muhiim u ah khadadka baakadaha badan, gaar ahaan warshadaha halkaas oo cabbiraadda saxda ah ay muhiim u tahay. Noocyo kala duwan oo mashiinno miisaan ah ayaa lagu lammaanayn karaa mashiinka baakadaha bacaha, mid walbana wuxuu bixiyaa faa'iidooyin gaar ah iyadoo ku xiran shuruudaha badeecada iyo baakadaha:

1. Miisaanno Madaxyo Badan leh

Isticmaalka: Ku habboon badeecooyinka granulated iyo kuwa aan caadiga ahayn sida cuntooyinka fudud, nacnaca, iyo cuntooyinka la qaboojiyey.

Shaqayn: Madaxyo miisaan oo badan ayaa isku mar shaqeeya si loo gaaro miisaan sax ah oo degdeg ah.

2. Miisaanno Toosan

Isticmaalka: Ku habboon badeecooyinka granular-ka ah ee si xor ah u socda sida sonkorta, milixda, iyo iniinyaha.

Hawlgalka: Wuxuu adeegsadaa kanaallo gariiraya si uu badeecada ugu quudiyo baaldiyada miisaanka, taasoo u oggolaanaysa miisaan joogto ah.

3. Buuxiyaasha Auger

Isticmaalka: Waxaa loogu talagalay badeecooyinka budada ah iyo kuwa la jarjaray sida burka, budada caanaha, iyo xawaashka.

Shaqada: Wuxuu adeegsadaa boolal auger ah si uu badeecada ugu shubo bacda, isagoo bixinaya buuxin la xakameeyey oo aan boodh lahayn.

4. Buuxiyaasha Koobka Volumetric

Isticmaalka: Si fiican ayuu ula shaqeeyaa alaabada si sax ah loogu cabbiri karo mugga, sida bariiska, digirta, iyo qalabka yar yar.

Shaqayn: Waxay adeegsataa koobab la hagaajin karo si loo cabbiro badeecada iyadoo loo eegayo mugga, iyadoo bixinaysa xal fudud oo kharash-ool ah.

5. Miisaannada Isku-dhafka ah

Isticmaalka: Waa mid aad u kala duwan, wuxuuna qaban karaa noocyo kala duwan oo badeecooyin ah, oo ay ku jiraan badeecooyin isku dhafan.

Shaqada: Waxay isku daraysaa sifooyinka miisaamannada kala duwan, taasoo u oggolaanaysa dabacsanaan iyo saxnaan marka la miisaamayo qaybaha kala duwan.

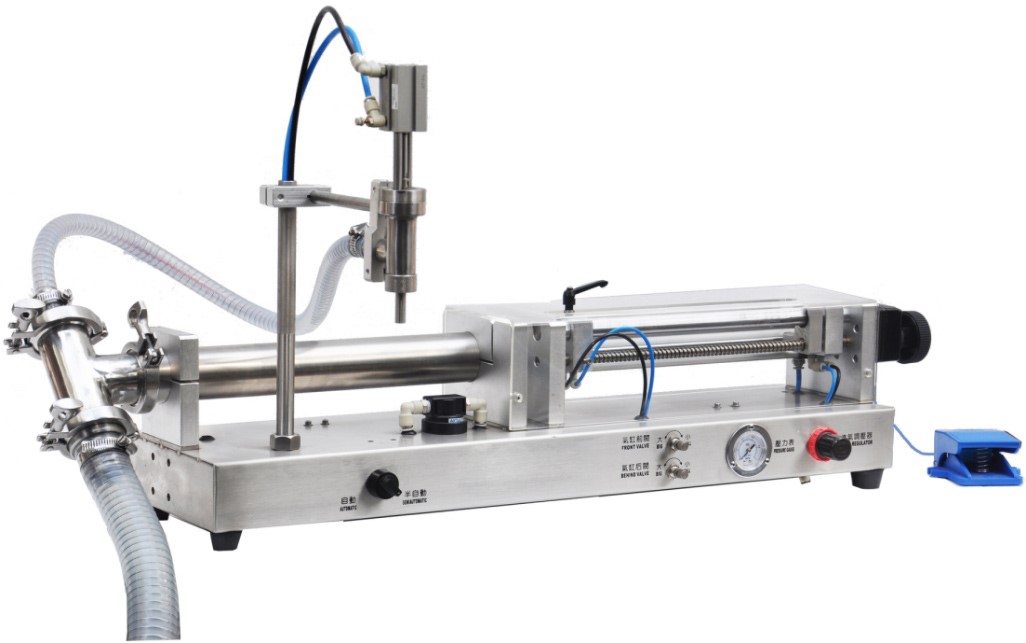

6. Waxyaabaha Buuxiya Dareeraha

Isticmaalka: Si gaar ah loogu talagalay dareerayaasha iyo dareere-baraha ah sida maraqa, saliidaha, iyo kareemada.

Shaqayn: Waxay isticmaashaa bambooyin ama cufisjiidadka si loo xakameeyo socodka dareeraha ee ku jira bacda, iyadoo la hubinayo buuxinta saxda ah oo aan daadanayn.

Gunaanad

Mashiinka baakadaha bacaha waa qalab badan oo lagama maarmaan u ah baahiyaha baakadaha casriga ah. Fahmidda noocyadooda, shaqadooda, iyo agabkooda ayaa fure u ah ka faa'iideysiga faa'iidooyinkooda kobaca ganacsiga. Maalgashiga mashiinka saxda ah wuxuu si weyn u wanaajin karaa hufnaanta, yareyn karaa qashinka, iyo hubin karaa tayada badeecada.

Smart Weigh waa hoggaamiye caalami ah oo ku takhasusay miisaaminta saxda ah iyo nidaamyada baakadaha isku dhafan, oo ay ku kalsoon yihiin 1,000+ macaamiil iyo 2,000+ khadadka baakadaha adduunka oo dhan. Iyada oo taageero maxalli ah laga helayo Indonesia, Yurub, Mareykanka iyo UAE , waxaanu bixinaa xalal khadka baakadaha ah oo laga bilaabo quudinta ilaa palletization.

Xiriir Degdeg ah

Mashiinka Baakaynta