Kusukela ngo-2012 - i-Smart Weight izibophezele ekusizeni amakhasimende ukwandisa umkhiqizo ngezindleko eziphansi.

Umhlahlandlela Ophelele Womshini Wokupakisha Izikhwama

Njengomkhiqizi ohamba phambili womshini wokupakisha izikhwama waseShayina, sivame ukuhlangana nemibuzo mayelana nezinhlobo, ukusebenza, kanye nezinto ezisetshenziswa kule mishini evela kumakhasimende. Yini eyenza imishini yokupakisha izikhwama ibaluleke kangaka embonini yokupakisha yanamuhla? Amabhizinisi angazisebenzisa kanjani ukuze asebenze kahle futhi azinze?

Imishini yokupakisha izikhwama ishintsha indlela imikhiqizo epakishwa ngayo, inikeza ukuguquguquka, ukunemba, kanye nokwenza ngokwezifiso. Inakekela izimboni ezahlukahlukene, okuhlanganisa ukudla, imithi, kanye nezimonyo, inikeza izixazululo ezenzelwe izidingo ezahlukene zokupakisha.

Ukuqonda le mishini kubalulekile kumabhizinisi afuna ukutshala imali ezixazululweni zokupakisha zesimanje. Ake sihlole umhlahlandlela ophelele wemishini yokupakisha izikhwama.

Yiziphi Izinzuzo Zomshini Wokupakisha Isikhwama?

Imishini yokupakisha izikhwama inikeza izinzuzo eziningi, njengokusebenza kahle okuthuthukisiwe, imfucuza encane, kanye nokuvikelwa komkhiqizo. Lezi zinzuzo zihumusheka kanjani ezisetshenzisweni zangempela?

Ukusebenza Kahle Okuthuthukisiwe : Imishini yokufaka amabhegi ngokuzenzakalela izenzekela imisebenzi ekhathazayo, yonga isikhathi kanye nezindleko zabasebenzi. Ngokusho kwempendulo yamakhasimende, ukuzenzakalela kungathuthukisa ukusebenza kahle ngamaphesenti afinyelela ku-40%.

Imfucuza Encane : Ukulawula okuzenzakalelayo kunciphisa izindleko zemfucuza yomkhiqizo kanye nezinto zokupakisha. Impendulo yamakhasimende ethu Ucwaningo lubonisa ukuthi ukuzenzakalela kunganciphisa imfucuza ngo-30%.

Izindleko zabasebenzi eziphansi : Imigqa yokugcwalisa ezenzakalelayo isiza amakhasimende ukuthi onge okungenani abasebenzi abangu-30%, uhlelo lomshini wokupakisha oluzenzakalelayo lusindisa abasebenzi abangu-80% uma kuqhathaniswa nokulinganisa nokupakisha kwendabuko.

Ukuvikelwa Komkhiqizo: Imishini engenziwa ngokwezifiso iqinisekisa ukuphepha komkhiqizo futhi inciphisa izingozi zokungcola.

Yiziphi Izinhlobo Zemishini Yokupakisha Izikhwama Etholakalayo?

Imishini yokupakisha izikhwama ihlukaniswe ngeMishini Yokupakisha Izikhwama Eyenziwe Ngaphambili, Imishini Yokugcwalisa Ifomu Eliqondile (VFFS) kanye Nemishini Yokugcwalisa Ifomu Eliqondile (HFFS). Yini ehlukanisa lezi zinhlobo?

Umshini Wokuvala Ifomu Eliqondile

Umshini Wokupakisha Isikhwama Esenziwe Ngaphambili : Wenzelwe ngokwezifiso ukugcwalisa izikhwama ezenziwe kakade ngemikhiqizo eyahlukahlukene, njengezikhwama ezisicaba ezenziwe kusengaphambili, izikhwama zokuma, isikhwama sedoy esineziphu, izikhwama ezineziphu eceleni, izikhwama zokuvala ezisemaceleni eziyi-8 kanye nezikhwama ze-sprout.

Imishini Yokufaka Izimpawu Zokugcwalisa Ifomu Eliqondile : Ilungele kokubili isivinini esincane nesiphezulu sokukhiqiza, le mishini idala amaphakethe ngomqulu wefilimu. Imishini yokufaka uphawu oluqondile oluqondile olusheshayo ikhethwa kakhulu ekudleni okulula okusebenza ngezinga elikhulu. Ngaphandle kwezikhwama zemicamelo ezijwayelekile ezimise okwesikhwama kanye namaphakethe anezimbobo, umshini wokupakisha oqondile ungakha nezikhwama ezivalwe kane, izikhwama eziphansi, izikhwama ezintathu eziseceleni kanye nezikhwama ezine eziseceleni.

Imishini ye-HFFS: Lolu hlobo lwemishini luvame ukusetshenziswa eYurophu, kufana ne-vffs, i-hffs ifaneleka emikhiqizweni eqinile, yento eyodwa, uketshezi, le mishini ipakisha imikhiqizo ezikhwameni ezisicaba, ezimile noma ngezifiso izikhwama ezinesimo esingajwayelekile.

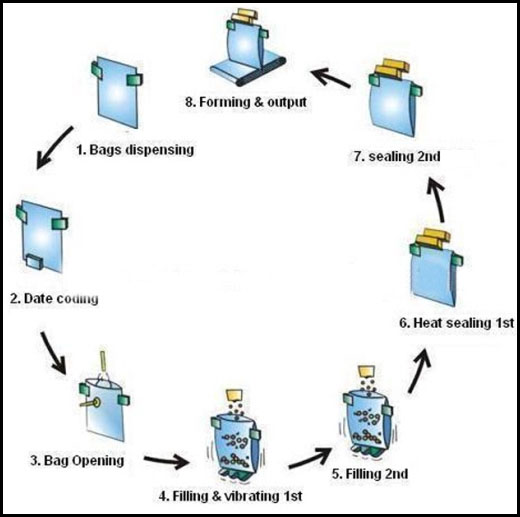

Usebenza Kanjani Umshini Wokupakisha Isikhwama Esenziwe Ngaphambili?

Umshini wokupakisha izikhwama owenziwe ngaphambilini uyimishini ekhethekile yokupakisha eyenzelwe ukugcwalisa nokuvala izikhwama esezivele zakhekile. Ngokungafani nemishini ye-Vertical Form Fill Seal (VFFS), edala izikhwama ngomqulu wefilimu, izikhwama zokubamba umshini wokupakisha izikhwama ezenziwe ngaphambilini esezivele zakhekile futhi zilungele ukugcwaliswa. Nansi indlela umshini wokupakisha izikhwama owenziwe ngaphambilini osebenza ngayo:

1. Ukulayisha Isikhwama

Ukulayisha Ngesandla: Abasebenzi bangafaka ngesandla izikhwama ezenziwe ngaphambilini ezibambeni zomshini.

Ukuqoqwa Okuzenzakalelayo: Eminye imishini inezinhlelo zokudla ezizenzakalelayo eziqoqwa futhi zibeke amaphakethe endaweni yawo.

2. Ukutholwa Nokuvulwa Kwesikhwama

Izinzwa: Umshini uthola ukuthi isikhwama sikhona futhi uqinisekise ukuthi sisendaweni efanele.

Indlela Yokuvula: Ama-gripper akhethekile noma izinhlelo ze-vacuum zivula isikhwama, zisilungiselele ukugcwalisa.

3. Ukuphrinta Usuku Ongakukhetha

Ukuphrinta: Uma kudingeka, umshini ungaphrinta ulwazi olufana nezinsuku zokuphelelwa yisikhathi, izinombolo zebhetshi, noma eminye imininingwane esikhwameni. Kulesi siteshi, imishini yokufaka izikhwama ingahlonyiswa ngephrinta yeribhoni, amaphrinta okudlulisa ukushisa (i-TTO) kanye nomshini wokubhala ikhodi we-laser.

4. Ukugcwalisa

Ukukhishwa Komkhiqizo: Umkhiqizo ukhishwa esikhwameni esivulekile. Lokhu kungenziwa kusetshenziswa izinhlelo ezahlukene zokugcwalisa, kuye ngohlobo lomkhiqizo (isb., uketshezi, impuphu, okuqinile).

5. Ukwehla kwamandla emali

Idivayisi yokwehlisa umoya ukuze isuse umoya owengeziwe esikhwameni ngaphambi kokuvala, iqinisekise ukuthi okuqukethwe kupakishwe kahle futhi kugcinwe. Le nqubo inciphisa umthamo ngaphakathi kwephakheji, okungaholela ekusetshenzisweni kahle kwendawo yokugcina futhi okungenzeka kuthuthukise impilo yeshelufu yomkhiqizo ngokunciphisa ukuchayeka ku-oxygen, into engase ifake isandla ekonakaleni noma ekuwohlokeni kwezinto ezithile. Ngaphezu kwalokho, ngokususa umoya owengeziwe, idivayisi yokwehlisa umoya ilungiselela isikhwama isinyathelo esilandelayo sokuvala, idale indawo efanele yokuvala okuphephile nokungaguquguquki. Lokhu kulungiselela kubalulekile ekugcineni ubuqotho bephakheji, ukuvimbela ukuvuza okungenzeka, nokuqinisekisa ukuthi umkhiqizo uhlala umusha futhi ungangcolisiwe ngesikhathi sokuthuthwa nokugcinwa.

6. Ukuvala

Imihlathi yokuvala efudumele noma ezinye izindlela zokuvala zisetshenziselwa ukuvala isikhwama ngokuphephile. Kubalulekile ukuqaphela ukuthi ukwakheka kwemihlathi yokuvala yezikhwama ezifakwe i-laminated kanye nezikhwama ze-PE (Polyethylene) kuhlukile, futhi izitayela zazo zokuvala ziyahlukahluka. Izikhwama ezifakwe i-laminated zingadinga izinga lokushisa elithile lokuvala kanye nengcindezi, kuyilapho izikhwama ze-PE zingadinga ukusethwa okuhlukile. Ngakho-ke, ukuqonda umehluko ezindleleni zokuvala kubalulekile, futhi kubalulekile ukwazi izinto zakho zephakheji kusenesikhathi.

7. Ukupholisa

Isikhwama esivaliwe singadlula esiteshini sokupholisa ukuze simise uphawu, uphawu lwesikhwama luyapholiswa ukuze kuvinjelwe ukuguquka ngenxa yokushisa okuphezulu esivalweni ngesikhathi sezinqubo zokupakisha ezilandelayo.

8. Ukukhishwa

Isikhwama esiqediwe sibe sesikhishwa emshinini, kungaba ngesandla ngumqhubi noma ngokuzenzakalelayo sifakwe ohlelweni lokuhambisa.

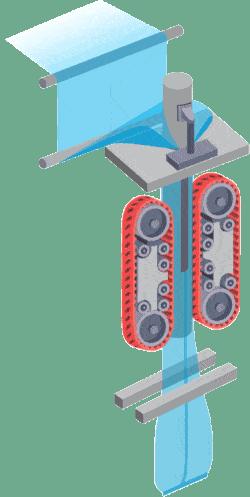

Isebenza Kanjani Imishini Yokugcwalisa Ifomu Eliqondile?

Imishini yokugcwalisa ifomu eliqondile (VFFS) iyindlela ethandwayo embonini yokupakisha ngenxa yokusebenza kahle kwayo kanye nokuguquguquka kwayo. Nansi indlela umshini we-VFFS osebenza ngayo, uhlukaniswe ngezigaba ezibalulekile:

Ukuvuleka Kwefilimu : Umqulu wefilimu ufakwa emshinini, bese ukhululeka njengoba uhamba phakathi nenqubo.

Uhlelo Lokudonsa Amafilimu : Ifilimu idonswa emshinini kusetshenziswa amabhande noma amarola, okuqinisekisa ukugeleza okubushelelezi nokungaguquguquki.

Ukuphrinta (Ongakukhetha): Uma kudingeka, ifilimu ingaphrintwa ngolwazi olufana nezinsuku, amakhodi, ama-logo, noma eminye imiklamo kusetshenziswa amaphrinta okushisa noma e-ink-jet.

Ukubekwa Kwefilimu : Izinzwa zibona indawo yefilimu, ziqinisekisa ukuthi iqondene kahle. Uma kutholakala noma yikuphi ukungalungi kahle, kwenziwa izinguquko zokubeka ifilimu endaweni entsha.

Ukwakheka Kwesikhwama : Ifilimu ifakwa phezu kwepayipi eliyindilinga elimise okwekhoni, liyibumbe ibe yisikhwama. Imiphetho emibili yangaphandle yefilimu iyahlangana noma iyahlangana, bese kwenziwa uphawu oluqondile ukuze kwakheke umthungo wangemuva wesikhwama.

Ukugcwalisa : Umkhiqizo ozopakishwa ufakwa esikhwameni esakhiwe. Ithuluzi lokugcwalisa, njengesikali esinezinhloko eziningi noma i-auger filler, liqinisekisa ukulinganiswa okufanele komkhiqizo.

Ukuvala Okuvundlile : Imihlathi yokuvala evundlile efudumele ihlangana ukuze ivale ingxenye ephezulu yesikhwama kanye nengxenye engezansi yesikhwama esilandelayo. Lokhu kudala uphawu oluphezulu lwesikhwama esisodwa kanye nophawu oluphansi lwesinye esilandelayo emgqeni.

Ukusikwa Kwesikhwama : Isikhwama esigcwalisiwe nesivaliwe siyasikwa kusuka efilimini eqhubekayo. Ukusikwa kungenziwa kusetshenziswa i-blade noma ukushisa, kuye ngomshini nezinto ezisetshenziswayo.

Ukuhambisa Izikhwama Eziqediwe : Izikhwama eziqediwe zibe sezithunyelwa esigabeni esilandelayo, njengokuhlola, ukulebula, noma ukupakisha emabhokisini.

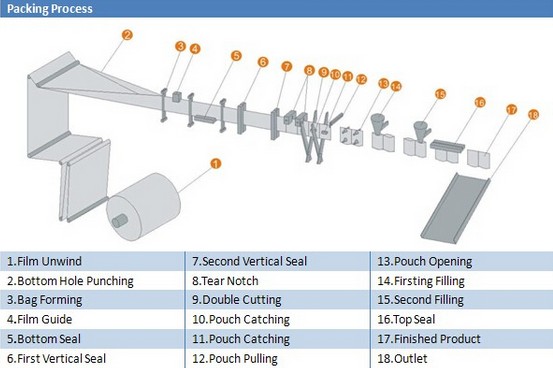

Isebenza Kanjani Imishini Yokugcwalisa Ifomu Elivundlile?

Umshini Wokugcwalisa Ifomu Elivundlile (i-HFFS) uhlobo lwemishini yokupakisha eyakha, igcwalise, futhi ivale imikhiqizo ngendlela evundlile. Ifaneleka kakhulu imikhiqizo eqinile noma ehlukaniswe ngokwehlukana, njengamabhisikidi, amaswidi, noma amadivayisi ezokwelapha. Nansi incazelo eningiliziwe yendlela umshini we-HFFS osebenza ngayo:

Ukuthuthwa Kwamafilimu

Ukukhululeka: Umqulu wefilimu ufakwa emshinini, bese ukhululeka ngokuvundlile njengoba inqubo iqala.

Ukulawula Ukucindezeleka: Ifilimu igcinwa iqinile ukuqinisekisa ukunyakaza okubushelelezi nokwakheka kwesikhwama okunembile.

Ukwakheka Kwesikhwama

Ukwakheka: Ifilimu ibunjwa ibe yisikhwama kusetshenziswa izikhunta ezikhethekile noma amathuluzi okubumba. Ukuma kungahluka ngokuya ngezidingo zomkhiqizo kanye nokupakishwa.

Ukuvala: Izinhlangothi zesikhwama zivalwe, ngokuvamile kusetshenziswa izindlela zokuvala ukushisa noma ze-ultrasonic.

Ukubeka Amafilimu Nokuqondisa

Izinzwa: Lezi zibona indawo yefilimu, ziqinisekisa ukuthi ibekwe kahle ukuze kutholakale isikhwama esinembile futhi sivalwe.

Ukuvala Okuqondile

Izinhlangothi eziqondile zesikhwama zivaliwe, okwenza kube khona imiphetho eseceleni yesikhwama. Yilapho igama elithi "ukuvalwa okuqondile" livela khona, yize umshini usebenza ngokuvundlile.

Ukusika Isikhwama

Ukusika kusuka kuFilimu Eqhubekayo bese uhlukanisa izikhwama ngazinye kusuka kuroli eqhubekayo yefilimu.

Ukuvulwa Kwesikhwama

Ukuvula Isikhwama: Umsebenzi wokuvula isikhwama uqinisekisa ukuthi isikhwama sivuliwe kahle futhi silungele ukwamukela umkhiqizo.

Ukuqondanisa: Isikhwama kumele siqondaniswe kahle ukuqinisekisa ukuthi indlela yokuvula ingafinyelela futhi ivuleke kahle isikhwama.

Ukugcwalisa

Ukukhishwa Komkhiqizo: Umkhiqizo ufakwa noma ukhishwa esikhwameni esakhiwe. Uhlobo lohlelo lokugcwalisa olusetshenziswayo luncike kumkhiqizo (isb., ukugcwalisa amandla adonsela phansi koketshezi, ukugcwalisa okunomthamo kwezinto eziqinile).

Ukugcwalisa Ngezigaba Eziningi (Ongakukhetha): Eminye imikhiqizo ingadinga izigaba noma izingxenye eziningi zokugcwalisa.

Ukuvala Okuphezulu

Ukuvala: Ingxenye ephezulu yesikhwama ivaliwe, okuqinisekisa ukuthi umkhiqizo ugcinwe kahle.

Ukusika: Isikhwama esivaliwe sibe sesihlukaniswa nefilimu eqhubekayo, kungaba ngensingo yokusika noma ngokushisa.

Ukudlulisa Isikhwama Esiqediwe

Amaphakethe aqediwe adluliselwa esigabeni esilandelayo, njengokuhlolwa, ukulebula, noma ukupakisha emabhokisini.

Yikuphi Okusetshenziselwa Ukupakisha Isikhwama?

Ukukhetha izinto zokwakha kubalulekile ukuze umkhiqizo ube nekhwalithi kanye nokusimama. Yiziphi izinto zokwakha ezivamile ezisetshenziswa ekupakisheni izikhwama?

Amafilimu epulasitiki : Kufaka phakathi amafilimu anezingqimba eziningi namafilimu anezingqimba eyodwa njengePolyethylene (PE), iPolypropylene (PP), kanye nePolyester (PET).

I-Aluminium Foil : Isetshenziselwa ukuvikela ngokuphelele izithiyo. Ucwaningo luqokomisa ukusetshenziswa kwayo.

Iphepha : Inketho ebolayo yezimpahla ezomile. Lolu cwaningo luxoxa ngezinzuzo zalo.

Iphakheji yokuphinda usebenzise : ukupakishwa kwe-mono-pe okuphinde kusetshenziswe

Uhlobo luni lomshini wokulinganisa ongasebenza nomshini wokupakisha izikhwama?

Ukuhlanganiswa kwemishini yokukala nezinhlelo zokupakisha izikhwama kuyisici esibalulekile emigqeni eminingi yokupakisha, ikakhulukazi ezimbonini lapho ukulinganisa okunembile kubalulekile khona. Izinhlobo ezahlukene zemishini yokukala zingahlanganiswa nomshini wokupakisha izikhwama, ngamunye unikeza izinzuzo ezihlukile kuye ngezidingo zomkhiqizo kanye nokupakisha:

1. Izikali Ezinezinhloko Eziningi

Ukusetshenziswa: Kuhle kakhulu emikhiqizweni ehlanganisiwe nengahlelekile efana nokudla okulula, amaswidi, nokudla okuqandisiwe.

Ukusebenza: Amakhanda amaningi okulinganisa asebenza ngesikhathi esisodwa ukuze kufezwe isisindo esinembile nesisheshayo.

2. Izikali Eziqondile

Ukusetshenziswa: Kufanelekela imikhiqizo egeleza ngokukhululeka njengoshukela, usawoti, kanye nembewu.

Ukusebenza: Isebenzisa iziteshi ezidlidlizayo ukuze ifake umkhiqizo emabhakedeni okulinganisa, okuvumela ukuthi ukale njalo.

3. Izigcwalisi ze-Auger

Ukusetshenziswa: Kwenzelwe imikhiqizo ewumpuphu necolekileyo efana nofulawa, i-milk powder, kanye nezinongo.

Ukusebenza: Isebenzisa isikulufu se-auger ukuze ifake umkhiqizo esikhwameni, inikeze ukugcwalisa okulawulwayo nokungenalo uthuli.

4. Izigcwalisi Zendebe Ezinomthamo

Ukusetshenziswa: Kusebenza kahle ngemikhiqizo engalinganiswa ngokunembile ngobuningi, njengelayisi, ubhontshisi, kanye nemishini encane.

Ukusebenza: Isebenzisa izinkomishi ezilungisekayo ukukala umkhiqizo ngevolumu, inikeza ikhambi elilula nelingabizi kakhulu.

5. Izikali Ezihlanganisiwe

Ukusetshenziswa: Kuguquguqukayo futhi kungaphatha imikhiqizo ehlukahlukene, kufaka phakathi imikhiqizo exubile.

Ukusebenza: Kuhlanganisa izici zezikali ezahlukene, okuvumela ukuguquguquka nokunemba ekulinganiseni izingxenye ezahlukene.

6. Ama-Liquid Fillers

Ukusetshenziswa: Kwenzelwe ngqo uketshezi kanye noketshezi oluyi-semi-liquid olufana nososo, uwoyela, kanye nokhilimu.

Ukusebenza: Isebenzisa amaphampu noma amandla adonsela phansi ukulawula ukugeleza koketshezi esikhwameni, iqinisekisa ukugcwaliswa okunembile nokungachitheki.

Isiphetho

Umshini wokupakisha izikhwama ungamathuluzi ahlukahlukene futhi abalulekile ezidingweni zokupakisha zesimanje. Ukuqonda izinhlobo zawo, ukusebenza kwawo, kanye nezinto zokwakha kubalulekile ekusebenziseni izinzuzo zawo ekukhuleni kwebhizinisi. Ukutshala imali emshinini ofanele kungathuthukisa kakhulu ukusebenza kahle, kunciphise imfucuza, futhi kuqinisekise ikhwalithi yomkhiqizo.

I-Smart Weight ingumholi womhlaba wonke ezinhlelweni zokupakisha ezinesisindo esinembile kakhulu nezihlanganisiwe, ethenjwa amakhasimende angaphezu kwe-1,000 kanye nemigqa yokupakisha engaphezu kwe-2,000 emhlabeni jikelele. Ngokusekelwa kwendawo e- Indonesia, eYurophu, e-USA nase-UAE , sinikeza izixazululo zomugqa wokupakisha we-turnkey kusukela ekuphakeleni kuya ekufakeni ama-pallet.

Isixhumanisi Esisheshayo

Umshini Wokupakisha