Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

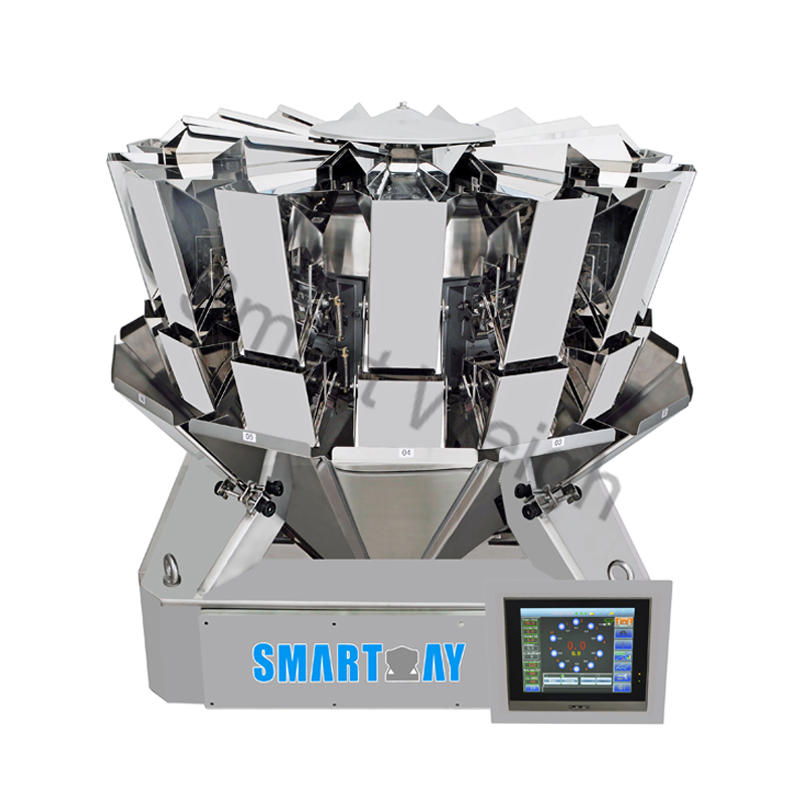

The quantitative weighing section of the combination weigher is the key equipment for the automated production of food factories. The previous average was imported from Japan and trucks. Due to the high price, it hindered the wide application and wide range of computer combination weighers. The emergence of scales and the high level of combination scale technology have made the computer combination multi-head scales that were originally regarded as "noble products" no longer the patents of large enterprises. More domestic enterprises pursuing high speed and high efficiency have eliminated them. In the past, the quantitative weighing and packaging production line of cup-type or full-manpower, which cost materials and labor, used a high-tech, more automated combination weigher quantitative weighing and packaging system to arm itself.

Let's take a look at the inherent characteristics of the multi head combination weigher in the food industry:

The multi-head computer combination weigher originated in Japan. Because the multi-head weigher has good performance in terms of accuracy and speed, it has been rapidly and widely used in the food industry. The multi-head weigher can weigh three types of materials: block, granular and strip. Among them, the weighing of block materials can reflect the superiority of the multi-head scale. It solves the measurement error caused by the large weight of the block material. The problem of penetration.

At the same time, the weighing error of the multihead weigher is generally set at 0.5-1.0g (weighing range 500g). At the same time, the performance of the multi-head computerized combination weigher in terms of packaging accuracy and speed is greatly improved compared to traditional measurement methods. , Because the multi-head weigher uses a computer to perform calculations, it effectively improves the combination speed (ie weighing speed). A multi-head weigher with ten heads can weigh up to 70 times per minute. A multi-head weigher with fourteen heads can weigh up to 70 times per minute. Up to 120 times per minute. A confectionery factory in Fujian is a large-scale enterprise specializing in the production of all kinds of candies.

Before 2004, it has been using traditional measurement methods (manual measurement), and its speed can only reach 25 times per minute, and the average error value of single bag weighing is greater than 4g, that is Each bag of candy (40g) packs at least 4g more candy due to inaccurate weighing. Calculated with an annual output of 4,000 tons, the company will lose nearly 400 tons of candy each year for this item alone to solve the inaccuracy of product measurement. After using the multi-head weigher, the company sets the actual weighing error value to about 1g, and the average error is 0.3-0.6g, that is, the weighing error loss of each bag of potato chips (40s) is reduced by more than 3 grams compared with when the multi-head weigher is not used. It is confirmed by cost accounting that the multi-head weigher has recovered all the investment in less than half a year, and the company has now used all its branches in all parts of the country.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved