Njengomkhiqizi ohamba phambili womshini wokupakisha izikhwama ovela e-China, sivame ukuhlangana nemibuzo mayelana nezinhlobo, ukusebenza, nezinto ezisetshenziswa kule mishini ezivela kumakhasimende. Yini eyenza imishini yokupakisha isikhwama ibaluleke kangaka embonini yanamuhla yokupakisha? Amabhizinisi angawasebenzisa kanjani amandla ukuze enze kahle futhi azinze?

Imishini yokupakisha izikhwama iguqula indlela imikhiqizo epakishwa ngayo, inikeza ukuguquguquka, ukunemba, nokwenza ngokwezifiso. Babhekelela izimboni ezahlukahlukene, ezihlanganisa ukudla, ezemithi, nezimonyo, ezihlinzeka ngezixazululo eziklanyelwe izidingo zokupakisha ezihlukene.

Ukuqonda le mishini kubalulekile emabhizinisini afuna ukutshala imali ezisombululweni zokupakisha zesimanje. Ake singene kumhlahlandlela ophelele wemishini yokupakisha yezikhwama.

Imishini yokupakisha izikhwama inikezela ngezinzuzo eziningi, njengokusebenza okuthuthukisiwe, ukumosha okuncane, nokuvikela umkhiqizo. Lezi zinzuzo zihumusheka kanjani ezinhlelweni zokusebenza zomhlaba wangempela?

Ukusebenza Okuthuthukisiwe: Imishini yokufaka izikhwama ngokuzenzakalelayo izenzela imisebenzi eyisicefe, yonga isikhathi nezindleko zabasebenzi. Ngokwempendulo yamakhasimende, i-automation ingathuthukisa ukusebenza kahle kuze kufike ku-40%.

Imfucuza Encane: Ukulawula okuzenzakalelayo kunciphisa udoti womkhiqizo nezindleko zempahla yokupakisha. Impendulo yamakhasimende ethu Ucwaningo lubonisa ukuthi ukuzenzela kunganciphisa imfucuza ngo-30%.

Izindleko zabasebenzi eziphansi: Imigqa yokugcwalisa e-Semi-automatic isiza amakhasimende ukuthi asindise okungenani abasebenzi abangama-30%, uhlelo lomshini wokupakisha othomathikhi lusindisa ukusebenza okungu-80% uma kuqhathaniswa nesisindo somuntu esijwayelekile kanye nokupakisha.

Ukuvikelwa Komkhiqizo: Imishini eyenziwe ngokwezifiso iqinisekisa ukuphepha komkhiqizo futhi inciphisa ubungozi bokungcola.

Imishini yokupakisha izikhwama ihlukaniswe ngeMishini Yokupakisha Yesikhwama Sesikhathi Sangaphambili, Imishini Yokugcwalisa Ifomu Eliqondile (VFFS) kanye NeMishini Yokugcwalisa Ifomu Evundlile (HFFS). Yini ehlukanisa lezi zinhlobo?

Umshini Wokuvala Ifomu Elimile

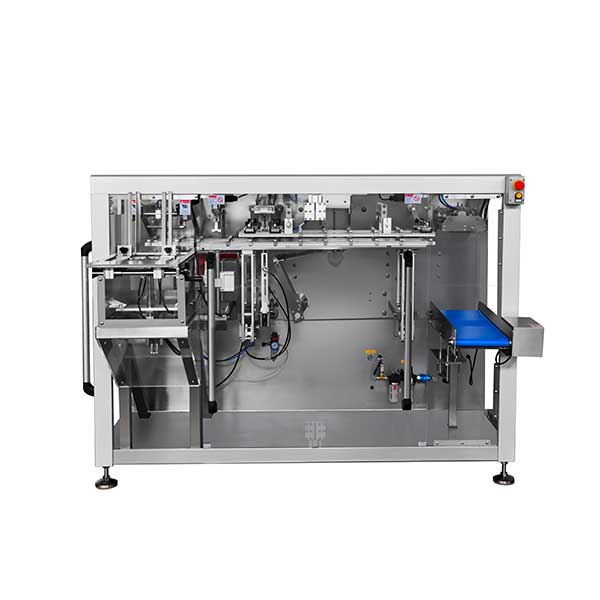

Umshini Wokupakisha Wezikhwama Owenziwe ngaphambilini: Idizayinelwe ngokwezifiso ukugcwalisa izikhwama ezenziwe ngomumo ngemikhiqizo ehlukahlukene, njengesikhwama sesikhwama esenziwe ngaphambilini esiyisicaba, izikhwama zokuma, i-doypack enoziphu, izikhwama ezifakwe emaceleni, izikhwama ezingu-8 ezivaliwe ezisemaceleni kanye nezikhwama ezihluma.

Imishini Yokuvala Ifomu Emile: Ilungele kokubili isivinini sokukhiqiza esincane nesiphezulu, le mishini idala izikhwama ezivela kumqulu wefilimu. Imishini yokugcwalisa i-High Speed vertical form yokugcwalisa ikhethwa ngokudla okulula ngemisebenzi emikhulu. Ngaphandle komumo wesikhwama ojwayelekile njengezikhwama zomcamelo kanye nezikhwama ezishisiwe, umshini wokupakisha ume mpo ungakha izikhwama ezivalwe kane, izikhwama eziphansi eziphansi, izikhwama ezi-3 ezisemaceleni nezi-4 ezisemaceleni.

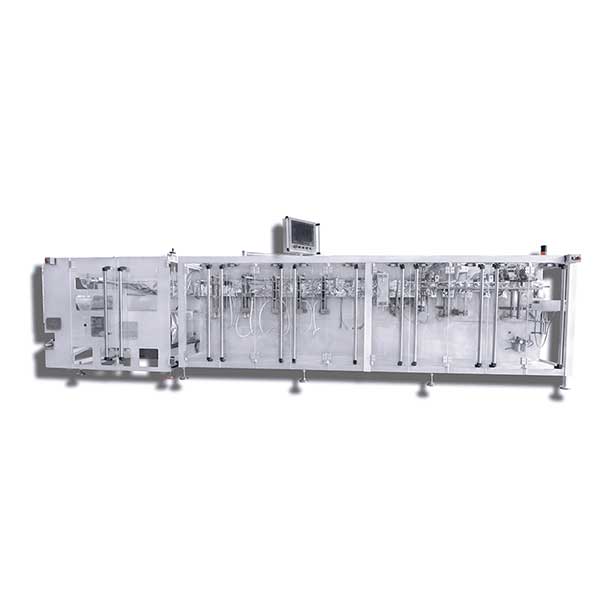

Imishini ye-HFFS: Lolu hlobo lwemishini luvamile ukusetshenziswa e-Europe, lufana nama-vffs, ama-hffs afanele imikhiqizo eqinile, yento eyodwa, uketshezi, le mishini ipakisha imikhiqizo endaweni eyisicaba, izikhwama zokuma noma ukwenza ngezifiso izikhwama zomumo ongajwayelekile.

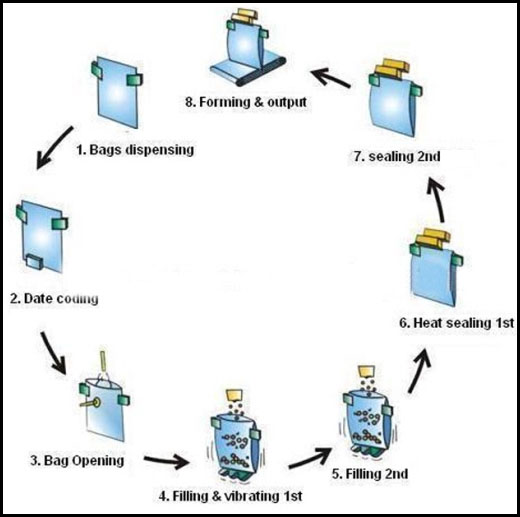

Umshini wokupakisha owenziwe kusengaphambili uyisisetshenziswa sokupakisha esikhethekile esiklanyelwe ukugcwalisa nokuvala izikhwama esezakhiwe kakade. Ngokungafani nemishini ye-Vertical Form Fill Seal (VFFS), eyenza izikhwama ezivela kumqulu wefilimu, izikhwama zomshini wokupakisha isikhwama esezivele zimile futhi zilungele ukugcwaliswa. Nansi indlela umshini wokupakisha owenziwe kusengaphambili osebenza ngayo:

1. Isikhwama Iyalayisha

Ukulayisha mathupha: Ama-Opharetha angabeka mathupha izikhwama ezenziwe ngaphambilini kubaphathi bomshini.

Ukucosha Okuzenzakalelayo: Eminye imishini inezinhlelo zokuphakela ezizenzakalelayo ezikhetha futhi zibeke izikhwama endaweni.

2. Ukutholwa Kwesikhwama Nokuvula

Izinzwa: Umshini uthola ubukhona besikhwama futhi uqinisekisa ukuthi sisendaweni efanele.

I-Opening Mechanism: Izibambo ezikhethekile noma amasistimu e-vacuum avula isikhwama, esilungiselela ukugcwaliswa.

3. Ukuphrinta Usuku Lokuzikhethela

Ukuphrinta: Uma kudingeka, umshini ungaphrinta ulwazi olufana nezinsuku zokuphelelwa yisikhathi, izinombolo zeqoqo, noma eminye imininingwane esikhwameni. Kulesi siteshi, imishini yokupakisha yesikhwama ingahlomisa iphrinta yeribhoni, amaphrinta okudlulisa i-Thermal (TTO) kanye nomshini wokufaka amakhodi we-laser.

4. Ukugcwalisa

Ukunikezwa Komkhiqizo: Umkhiqizo ukhishelwa esikhwameni esivulekile. Lokhu kungenziwa ngokusebenzisa izinhlelo ezihlukahlukene zokugcwalisa, kuye ngokuthi uhlobo lomkhiqizo (isb., uketshezi, impuphu, okuqinile).

5. Ukwehla kwamandla emali

Idivayisi yokunciphisa umoya yokukhipha umoya omningi esikhwameni ngaphambi kokuvala, iqinisekisa ukuthi okuqukethwe kupakishwe ngokuqinile futhi kuyalondolozwa. Le nqubo inciphisa ivolumu ngaphakathi kokupakishwa, okungaholela ekusetshenzisweni kahle kakhudlwana kwendawo yokugcina futhi okungenzeka kuthuthukise impilo yeshalofu yomkhiqizo ngokunciphisa ukuchayeka kumoya-mpilo, into engase ibe nomthelela ekonakaleni noma ekonakaleni kwezinto ezithile. Ukwengeza, ngokukhipha umoya oweqile, idivayisi yokunciphisa umoya ilungiselela isikhwama isinyathelo esilandelayo sokuvala, okwenza indawo ekahle yokuvalwa okuvikelekile nokungaguquguquki. Lokhu kulungiselelwa kubalulekile ekugcineni ubuqotho bephakheji, ukuvimbela ukuvuza okungenzeka, kanye nokuqinisekisa ukuthi umkhiqizo uhlala umusha futhi ungangcolisiwe ngesikhathi sokuthutha nokugcinwa.

6. Ukubekwa uphawu

Imihlathi yokuvala eshisayo noma ezinye izindlela zokuvala zisetshenziselwa ukuvala isikhwama ngokuvikelekile. Kubalulekile ukuqaphela ukuthi ukuklanywa kwemihlathi yokuvala amaphakethe ane-laminated kanye nezikhwama ze-PE (Polyethylene) kuhlukile, futhi izitayela zabo zokuvala ziyahlukahluka futhi. Amaphakethe ane-laminated angase adinge izinga lokushisa elithile lokuvala nokucindezela, kuyilapho amaphakethe e-PE angase adinge ukulungiselelwa okuhlukile. Ngakho-ke, ukuqonda umehluko wezindlela zokuvala kubalulekile, futhi kubalulekile ukwazi impahla yephakheji lakho kusenesikhathi.

7. Ukupholisa

Isikhwama esivalekile singase sidlule esiteshini sokupholisa ukuze sibeke uphawu, isikhwama sesikhwama siyapholiswa ukuze kuvinjelwe ukuwohloka ngenxa yokushisa okuphezulu esicini ngesikhathi sezinqubo zokupakisha ezilandelayo.

8. Ukukhipha

Isikhwama esiqediwe sibe sesikhishwa emshinini, kungaba ngesandla ngu-opharetha noma ngokuzenzakalelayo singene kusistimu yokuthutha.

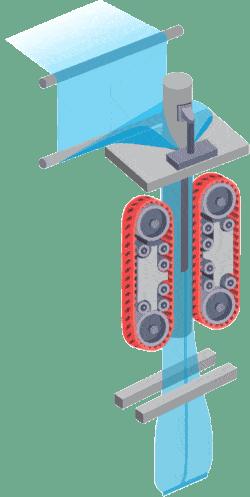

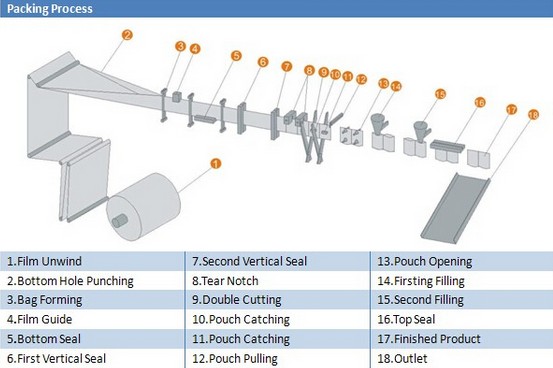

Imishini ye-Vertical Form Fill Seal (VFFS) iyisinqumo esidumile embonini yokupakisha ngokusebenza kahle kwayo nokuguquguquka. Nansi indlela umshini we-VFFS osebenza ngayo, ohlukaniswe waba yizigaba ezibalulekile:

Ukukhulula Ifilimu: Umqulu wefilimu ulayishwa emshinini, futhi awulimele njengoba uhamba phakathi nenqubo.

Isistimu Yokudonsa Ifilimu: Ifilimu idonswa ngomshini usebenzisa amabhande noma ama-roller, ukuqinisekisa ukugeleza okubushelelezi nokuhambisanayo.

Ukuphrinta (Ongakukhetha): Uma kudingekile, ifilimu ingaphrintwa ngolwazi olufana nezinsuku, amakhodi, amalogo, noma amanye amadizayini kusetshenziswa amaphrinta ashisayo noma ayi-ink-jet.

Ukuma kwefilimu: Izinzwa zithola indawo yefilimu, ziqinisekisa ukuthi iqondaniswe kahle. Uma kutholwa noma yikuphi ukungahambi kahle, kwenziwa izinguquko ukuze ifilimu ibekwe kabusha.

Ukwakhiwa Kwesikhwama: Ifilimu idliswa phezu kweshubhu elenza okumise okwekhoni, ililolonge libe yisikhwama. Amaphethelo amabili angaphandle efilimu ayadlulana noma ayahlangana, futhi uphawu oluqondile lwenziwa ukudala umthungo ongemuva wesikhwama.

Ukugcwalisa: Umkhiqizo ozopakishwa wehliselwa esikhwameni esakhiwe. Imishini yokugcwalisa, njengesikali esinamakhanda amaningi noma i-auger filler, iqinisekisa ukukalwa okufanele komkhiqizo.

Ukuvalwa Okuvundlile: Imihlathi yokuvala evundlile eshisayo iyajoyina ukuze kuvalwe phezulu kwesikhwama esisodwa kanye naphansi kwesinye. Lokhu kudala uphawu olungaphezulu lwesikhwama esisodwa kanye nophawu olungaphansi kwesinye emgqeni.

Isikhwama Sika: Isikhwama esigcwele savalwa sibe sesinqunywa efilimini eqhubekayo. Ukusika kungenziwa ngokusebenzisa i-blade noma ukushisa, kuye ngomshini nezinto ezibonakalayo.

Uqedile Ukuhambisa Isikhwama: Izikhwama eziqediwe zibe sezidluliselwa esigabeni esilandelayo, njengokuhlola, ukulebula, noma ukupakishwa emakhathoni.

Umshini Wokugcwalisa Ifomu Elivundlile (HFFS) uwuhlobo lwempahla yokupakisha eyakha, igcwalise, futhi ivale imikhiqizo ngendlela evundlile. Ifaneleka ngokukhethekile imikhiqizo eqinile noma ehlukaniswe ngamanye, njengamabhisikidi, amaswidi, noma izinsiza zezokwelapha. Nansi incazelo enemininingwane yokuthi umshini we-HFFS usebenza kanjani:

Ifilimu Ezokuthutha

Ukuqaqa: Umqulu wefilimu ulayishwa emshinini, futhi uyavuleka uvundlile njengoba inqubo iqala.

Ukulawula Ukuqina: Ifilimu igcinwa isesimweni sokuqina ukuze kuqinisekiswe ukunyakaza okushelelayo kanye nokwakheka kwesikhwama okunembile.

Ukwakhiwa Kwesikhwama

Ukubumba: Ifilimu ibunjwa ibe yisikhwama kusetshenziswa isikhunta esikhethekile noma amathuluzi okubumba. Umumo ungahluka ngokuya ngomkhiqizo kanye nezidingo zokupakisha.

Ukuvalwa: Izinhlangothi zesikhwama zivaliwe, ngokuvamile kusetshenziswa ukushisa noma izindlela zokuvala ze-ultrasonic.

Ukuma Kwefilimu Nokuqondisa

Izinzwa: Lezi zibona indawo yefilimu, ziqinisekisa ukuthi iqondaniswe kahle ukuze kwenziwe isikhwama esinembile futhi sivalwe.

Ukuvalwa Okuqondile

Amaphethelo aqondile esikhwama avaliwe, okwenza imithungo eseceleni yesikhwama. Lapha yilapho igama elithi "vertical sealing" livela khona, nakuba umshini usebenza ngokuvundlile.

Ukusika Isikhwama

Ukusika kufilimu eqhubekayo nokuhlukanisa izikhwama zomuntu ngamunye kusukela kumqulu oqhubekayo wefilimu.

Ukuvula Isikhwama

Ukuvula Isikhwama: Umsebenzi wokuvula isikhwama uqinisekisa ukuthi isikhwama sivulwe kahle futhi silungele ukwamukela umkhiqizo.

Ukuqondanisa: Isikhwama kufanele siqondaniswe kahle ukuze kuqinisekiswe ukuthi indlela yokuvula ingafinyelela futhi ivule isikhwama ngempumelelo.

Ukugcwalisa

Ukusabalaliswa Komkhiqizo: Umkhiqizo ufakwa noma ukhishwe esikhwameni esakhiwe. Uhlobo lwesistimu yokugcwalisa esetshenzisiwe incike kumkhiqizo (isb., ukugcwaliswa kwamandla adonsela phansi oketshezi, ukugcwaliswa kwe-volumetric kokuqinile).

Ukugcwaliswa Kwezigaba Eziningi (Ngokuzithandela): Eminye imikhiqizo ingadinga izigaba eziningi zokugcwalisa noma izingxenye.

Ukuvalwa Okuphezulu

Ukuvala: Ingaphezulu lesikhwama livaliwe, kuqinisekisa ukuthi umkhiqizo ugcinwe ngokuvikelekile.

Ukusika: Isikhwama esivaliwe sibe sesihlukaniswa nefilimu eqhubekayo, kungaba nge-blade yokusika noma ukushisa.

Kuqedwe Ukudlulisa Isikhwama

Izikhwama eziqediwe zidluliselwa esigabeni esilandelayo, njengokuhlola, ukulebula, noma ukupakishwa emakhathoni.

Ukukhethwa kwempahla kubalulekile kwikhwalithi nokusimama komkhiqizo. Yiziphi izinto ezijwayelekile ezisetshenziswa ekufakweni kwesikhwama?

Amafilimu Epulasitiki: Kubandakanya amafilimu ezendlalelo eziningi namafilimu anesendlalelo esisodwa njenge-Polyethylene (PE), i-Polypropylene (PP), ne-Polyester (PET).

I-Aluminium Foil: Isetshenziselwa ukuvikela okuphelele kwesithiyo. Ucwaningo lugqamisa ukusetshenziswa kwalo.

Iphepha: Inketho ye-biodegradable yezimpahla ezomile. Lolu cwaningo ludingida izinzuzo zalo.

Sebenzisa kabusha iphakheji: i-mono-pe egaywa kabusha

Ukuhlanganiswa kwemishini yokukala enezinhlelo zokupakisha izikhwama kuyisici esibucayi semigqa eminingi yokupakisha, ikakhulukazi ezimbonini lapho izilinganiso ezinembile zibalulekile. Izinhlobo ezahlukahlukene zemishini yokukala zingabhangqwa nomshini wokupakisha isikhwama, ngayinye inikezela ngezinzuzo ezihlukile ngokuya ngomkhiqizo nezidingo zokupakisha:

Ukusetshenziswa: Kulungele imikhiqizo eyimbudumbudu nengajwayelekile njengokudla okulula, amaswidi, nokudla okufriziwe.

Ukusebenza: Amakhanda okukala amaningi asebenza ngesikhathi esisodwa ukuze athole isisindo esinembile nesisheshayo.

Ukusetshenziswa: Ifanele imikhiqizo ye-granular egeleza mahhala njengoshukela, usawoti, kanye nembewu.

Ukusebenza: Isebenzisa amashaneli adlidlizayo ukuze ifake umkhiqizo kumabhakede esikali, okuvumela ukukala okuqhubekayo.

Ukusetshenziswa: Kudizayinelwe imikhiqizo eyimpuphu kanye ne-cone-grained njengofulawa, impushana yobisi, nezinongo.

Ukusebenza: Isebenzisa isikulufu se-auger ukuze ikhiphe umkhiqizo esikhwameni, inikeze ukugcwaliswa okulawulwayo nokungenalo izintuli.

Ukusetshenziswa: Isebenza kahle ngemikhiqizo engalinganiswa ngokunembile ngevolumu, njengerayisi, ubhontshisi, nezingxenyekazi zekhompyutha ezincane.

Ukusebenza: Iqasha izinkomishi ezilungisekayo ukukala umkhiqizo ngevolumu, ihlinzeka ngesixazululo esilula nesingabizi.

Ukusetshenziswa: Kuyaguquguquka futhi kungaphatha inhlobonhlobo yemikhiqizo, kuhlanganisa nemikhiqizo exubile.

Ukusebenza: Kuhlanganisa izici zezikali ezihlukene, okuvumela ukuguquguquka nokunemba ekukaleni izingxenye ezihlukahlukene.

Ukusetshenziswa: Idizayinelwe ngokukhethekile uketshezi noketshezi oluncane njengamasoso, uwoyela, nokhilimu.

Ukusebenza: Isebenzisa amaphampu noma amandla adonsela phansi ukuze ilawule ukugeleza koketshezi esikhwameni, iqinisekisa ukugcwaliswa okunembile nokungachitheki.

Umshini wokupakisha isikhwama ungamathuluzi ahlukahlukene futhi abalulekile ezidingo zesimanje zokupakisha. Ukuqonda izinhlobo zabo, ukusebenza, kanye nezinto zokwakha kuyisihluthulelo sokusebenzisa izinzuzo zabo ekukhuleni kwebhizinisi. Ukutshala imali emshinini ofanele kungathuthukisa kakhulu ukusebenza kahle, kunciphise ukungcola, futhi kuqinisekise ikhwalithi yomkhiqizo.

XHUMANA NATHI

Isakhiwo B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Sikwenza Kanjani Ukuhlangana Futhi Sichaze Umhlaba jikelele

Imishini Yokupakisha Ehlobene

Xhumana nathi, singakunikeza izixazululo ze-turnkey zokupakisha ukudla

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | Wonke Amalungelo Agodliwe