Peb lub tshuab granule packing muaj ntau yam kev ua haujlwm siab tshaj plaws uas txhim khu kev ntim khoom noj kom zoo thiab raug. Cov cwj pwm tseem ceeb suav nrog kev tuav cov khoom lag luam kom txo qis kev tawg, muaj peev xwm ntim ceev ceev, tsis siv neeg calibration rau cov khoom hnyav sib xws, thiab kev tswj xyuas qhov sib txawv. Cov txheej txheem no sawv cev rau kev nqis peev tseem ceeb hauv cov khoom lag luam ntim khoom noj khoom haus, muab kev ua haujlwm tsis sib xws thiab tsim khoom ntawm tus nqi sib tw granule packing tshuab.

Ntawm peb lub tuam txhab, peb tshwj xeeb hauv kev muab cov kev daws teeb meem siab tshaj plaws rau kev ntim khoom ntau yam, tshwj xeeb yog cereals. Peb Granule Packing Tshuab yog tsim los kom muaj txiaj ntsig zoo thiab raug ntim cov khoom noj hauv ntau lub hnab ntau thiab tsawg. Nrog rau kev siv technology thiab precision engineering, peb lub tshuab ua kom zoo sib xws thiab zoo hauv txhua pob. Peb txaus siab rau peb tus kheej ntawm kev xa cov kev daws teeb meem tshiab uas ua kom yooj yim rau kev ua haujlwm thiab ua kom muaj txiaj ntsig zoo rau peb cov neeg siv khoom. Cia siab rau peb los muab cov kev daws teeb meem zoo thiab muaj txiaj ntsig zoo uas ua tau raws li koj cov kev xav tau tshwj xeeb thiab tshaj qhov koj xav tau. Nrog peb, koj tuaj yeem tso siab rau qhov zoo thiab kev ua haujlwm ntawm peb cov khoom.

Nrog rau kev cog lus muaj zog rau kev tsim kho tshiab thiab kev ua haujlwm zoo, peb lub tuam txhab tshwj xeeb hauv kev muab cov kev daws teeb meem siab tshaj plaws rau kev lag luam ntim khoom. Peb Granule Packing Tshuab yog tsim los txhim kho cov txheej txheem ntau lawm rau cov khoom ntim khoom noj, muab cov kev ua tau zoo thiab ceev kom tau raws li qhov xav tau ntawm cov chaw tsim khoom niaj hnub no. Nrog rau kev tsom mus rau kev ntseeg tau thiab kev ua haujlwm zoo rau cov neeg siv khoom, peb lub tshuab tau nruab nrog cov cuab yeej siv thev naus laus zis los xyuas kom meej cov txiaj ntsig zoo thiab ntim tau zoo. Los ntawm kev pib me me mus rau cov tuam txhab loj, peb lub tuam txhab txaus siab rau nws tus kheej ntawm kev xa cov kev daws teeb meem uas txhim kho cov khoom tsim tau thiab cov txiaj ntsig zoo rau peb cov neeg siv khoom. Muaj kev paub txog yav tom ntej ntawm kev ntim khoom automation nrog peb Granule Packing Machine.

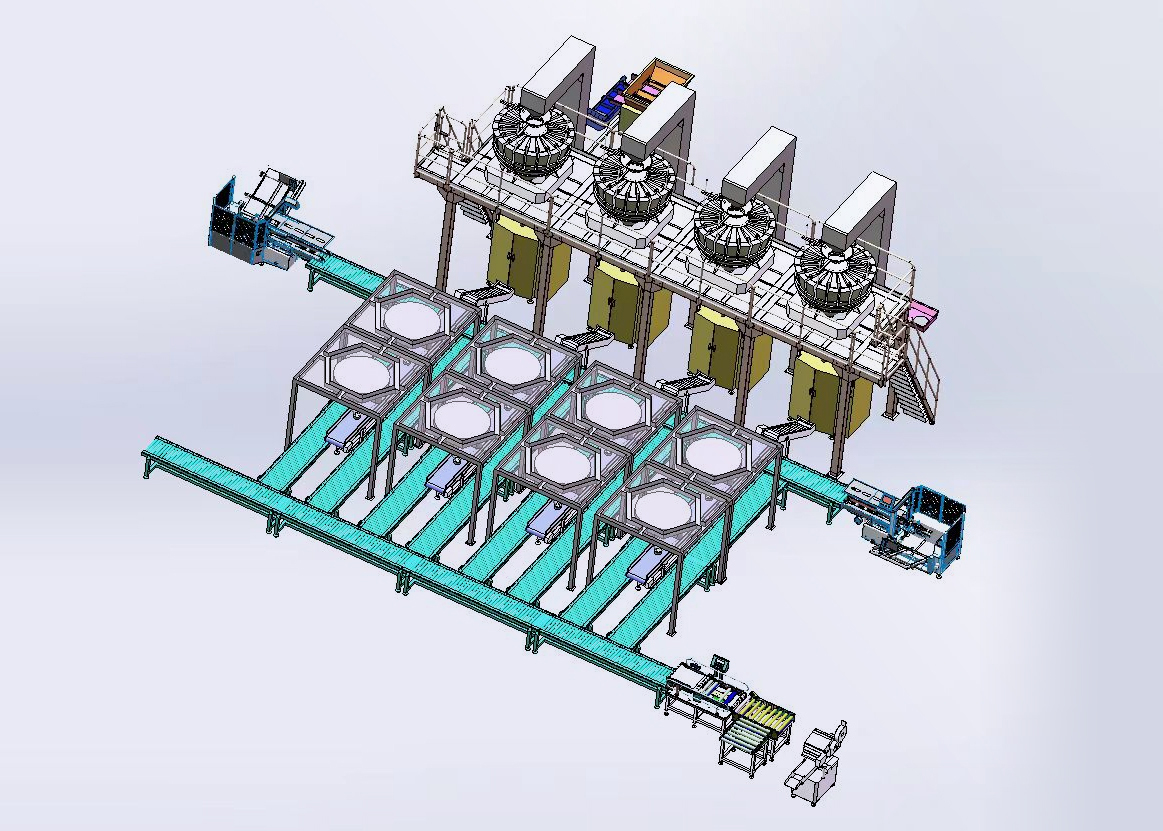

Nyob rau hauv lub forefront ntawm cereal ntim tshuab, peb tag nrho tsis siv neeg ntim system sawv cev rau ib tug tseem ceeb kev nce qib ntawm cov pa ntim daws teeb meem. Engineered tshwj xeeb rau cov cereals noj tshais, granolas, thiab cov khoom noj qhuav zoo sib xws, qhov kev sib xyaw ua ke no ua tiav qhov kev ua haujlwm tsis tau pom dua, txo cov kev cuam tshuam tib neeg txog li 85% piv rau kev ua haujlwm lwm txoj haujlwm.

Lub system architecture siv PLC kev sib koom ua ke thoob plaws tag nrho cov khoom, tsim kom muaj kev sib haum xeeb ntawm cov khoom pib noj los ntawm palletization. Peb cov cuab yeej siv tshuab synchronization tswj kev sib txuas lus zoo ntawm cov khoom, tshem tawm cov micro-stops thiab kev ua haujlwm tsis zoo hauv cov tshuab nrog cov txheej txheem tswj tsis sib xws. Cov ntaub ntawv tsim tawm lub sijhawm tiag tiag tau soj ntsuam tas li los ntawm peb cov kev tswj hwm kev hloov pauv, hloov kho tsis tu ncua kom tswj tau qhov kev ua tau zoo txawm tias muaj kev hloov pauv hauv cov khoom lag luam lossis ib puag ncig.

1. Thoob Conveyor System

2. High-Precision Multihead Weigher

3. Ergonomic Support Platform

4. Advanced Vertical Form Sau Foob Tshuab

5. Chaw Tswj Xyuas Kev Tswj Xyuas Zoo

6. High-Speed Output Conveyor

7. Tsis siv neeg Boxing System

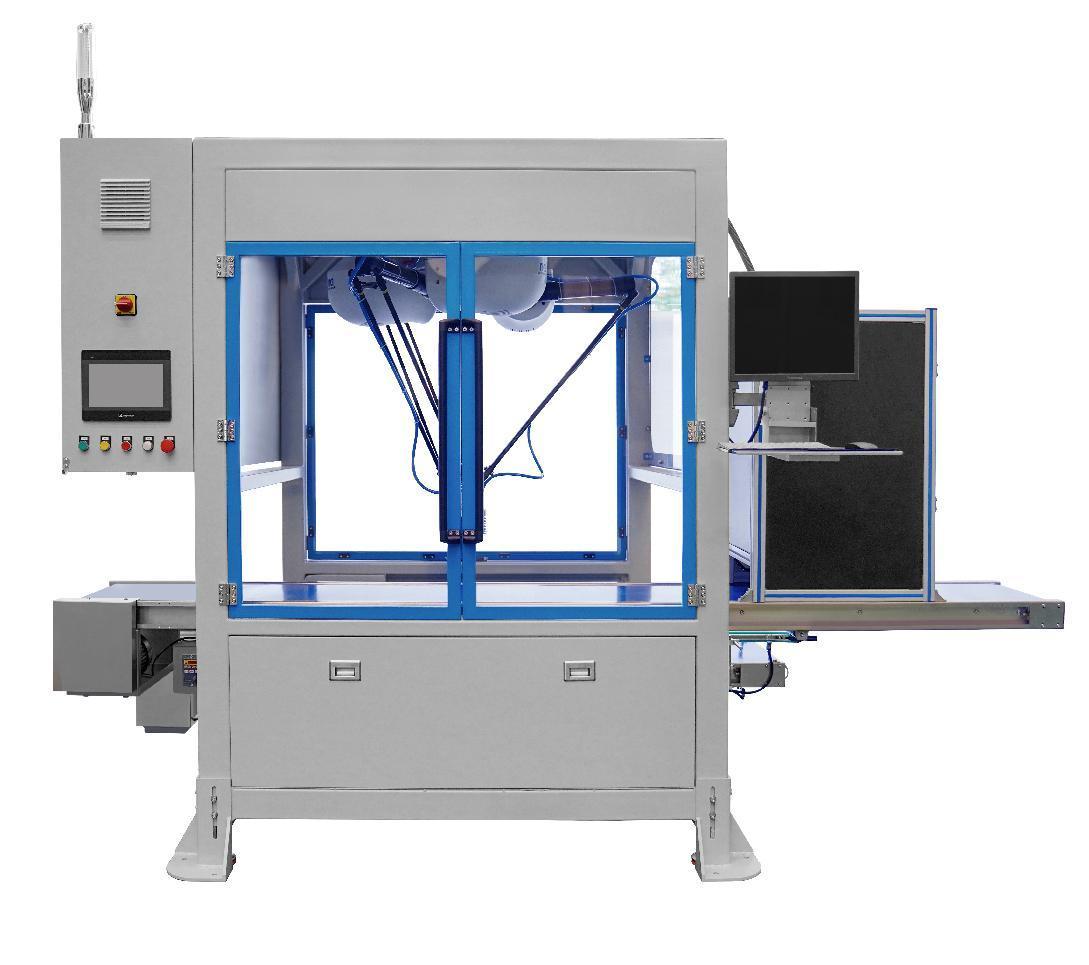

8. Delta Robot Pick-and-Place Unit

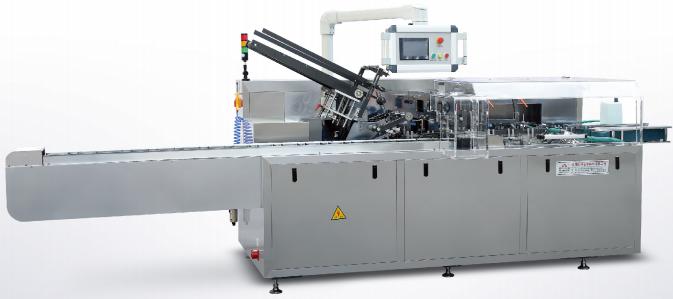

9. Ntse Cartoning Tshuab thiab Carton Sealer

10. Integrated Palletizing System

| Qhov hnyav | 100-2000 grams |

| Ceev | 30-180 pob / min (nyob ntawm cov qauv tshuab), 5-8 rooj plaub / min |

| Hnab Style | Hnab hauv ncoo, hnab gusset |

| Hnab Loj | Ntev 160-350mm, dav 80-250mm |

| Cov khoom siv zaj duab xis | Laminated zaj duab xis, ib txheej zaj duab xis |

| Zaj duab xis Thickness | 0.04-0.09 hli |

| Tswj Penal | 7 "los yog 9.7" Kov Screen |

| Fais fab mov | 220V / 50 Hz lossis 60 Hz |

1. Thoob Conveyor System

◆ Kev tuav cov khoom lag luam maj mam txo qhov kev tawg ntawm cov khoom noj uas muag

◆ Cov qauv tsim los tiv thaiv kev sib kis thiab txo cov plua plav

◆ Kev thauj mus los ntsug ua kom zoo tshaj plaws hauv pem teb siv

◆ Cov kev tu ncua tsawg nrog kev tu tus kheej muaj peev xwm

◆ Adjustable ceev tswj kom phim cov kab ntau lawm

2. High-Precision Multihead Weigher

◆ 99.9% qhov tseeb guarantees zoo ib yam pob luj

◆ Lub voj voog nrawm nrawm (txog 120 qhov hnyav ib feeb)

◆ Customizable feem tswj rau txawv pob qhov ntau thiab tsawg

◆ Tsis siv neeg calibration tuav precision thoob plaws hauv ntau lawm

◆ Kev tswj cov ntawv qhia zaub mov tso cai hloov khoom sai

3. Ergonomic Support Platform

◆ Kho qhov siab qhov chaw txo cov neeg ua haujlwm qaug zog

◆ Integrated kev ruaj ntseg railings raws li tag nrho cov kev cai ntawm kev nyab xeeb chaw ua hauj lwm

◆ Tsim los tiv thaiv kev vibration kom ruaj khov thiab ua haujlwm zoo

◆ Cov cuab yeej-dawb tu cov ntsiab lus txo qis qis qis

4. Advanced Vertical Form Sau Foob Tshuab

◆ Ntim ceev (txog 120 hnab ib feeb)

◆ Ntau lub hnab style xaiv (hauv ncoo, gusseted)

◆ Ceev-hloov zaj duab xis yob nrog nws pib-spling

◆ Gas-flush muaj peev xwm ua kom lub neej ntev

◆ Servo-tsav precision ua kom cov ntsaws ruaj ruaj zoo txhua zaus

5. Chaw Tswj Xyuas Kev Tswj Xyuas Zoo

◆ Muaj peev xwm txheeb xyuas cov hlau kom muaj kev nyab xeeb tshaj plaws ntawm cov zaub mov

◆ Checkweigher validation tshem tawm cov pob khoom hauv qab / hnyav dua

◆ Tsis siv neeg tsis lees paub cov txheej txheem rau cov pob khoom tsis raug

6. Chain Output Conveyor

◆ Kev hloov khoom lag luam du ntawm cov txheej txheem ntim khoom

◆ Muaj peev xwm ua kom tsis txhob muaj ntau qhov sib txawv

◆ Modular tsim kho kom haum raws li qhov yuav tsum tau ua ntawm qhov chaw layout

◆ Advanced tracking system tswj kev taw qhia pob

◆ Qhov chaw ntxuav yooj yim ua tau raws li cov qauv kev nyab xeeb ntawm zaub mov

7. Tsis siv neeg Boxing System

◆ Configurable case qauv rau txawv khw muag khoom yuav tsum tau

◆ Integrated box erector nrog kub-melt nplaum daim ntawv thov

◆ Kev ua haujlwm siab ceev (txog 30 kis ib feeb)

◆ Cov cuab yeej hloov ceev rau ntau lub thawv loj

8. Delta Robot Pick-and-Place Unit

◆ Kev ua haujlwm ceev ceev (txog 60 tus neeg xaiv ib feeb rau 500g pob)

◆ Lub zeem muag qhia qhov tseeb rau qhov chaw zoo meej

◆ Kev npaj txoj kev ntse txo qis zog rau kev siv zog

◆ Kev ua haujlwm yooj yim tuav ntau hom pob

◆ Compact footprint optimizes Hoobkas hauv pem teb chaw

9. Ntse Cartoning Tshuab

◆ Tsis siv neeg lub thawv pub mis thiab tsim

◆ Kev txheeb xyuas cov khoom pov tseg tshem tawm cov thawv khoob

◆ Kev ua haujlwm siab ceev nrog kev poob qis tsawg

◆ Qhov ntau thiab tsawg ntawm lub thawv tsis muaj kev hloov pauv ntau

10. Integrated Palletizing System

◆ Ntau lub pallet qauv xaiv rau kev ruaj ntseg zoo

◆ Tsis siv neeg pallet dispensing thiab stretch wrapping

◆ Integrated daim ntawv thov rau logistics taug qab

◆ Load optimization software maximizes shipping efficiency

◆ Tus neeg siv-phooj ywg qauv programming interface

1. Yuav tsum muaj kev txawj ntse npaum li cas rau kev khiav lag luam no?

Ib tus neeg ua haujlwm ib leeg nrog 3-5 hnub ntawm kev cob qhia tuaj yeem tswj hwm tag nrho cov txheej txheem los ntawm qhov nruab nrab HMI interface. Lub kaw lus muaj xws li intuitive touchscreen tswj nrog peb qib nkag: Tus neeg teb xov tooj (cov haujlwm yooj yim), Tus Saib Xyuas (kev hloov pauv), thiab Tus Kws Kho Mob (kev tu thiab kuaj mob). Kev them nyiaj yug tej thaj chaw deb muaj rau kev daws teeb meem siab heev.

2. Lub kaw lus ua haujlwm li cas cov khoom lag luam sib txawv?

Lub kaw lus khaws cia txog 200 daim ntawv qhia cov khoom lag luam nrog cov kev txwv tshwj xeeb rau txhua hom cereal. Cov no suav nrog kev noj zaub mov kom zoo, cov qauv kev vibration rau ntau lub taub hau hnyav, foob qhov kub thiab txias, thiab cov khoom siv tshwj xeeb tuav. Cov khoom hloov pauv tau raug ua tiav los ntawm HMI nrog kev hloov kho tshuab tsis siv neeg uas yuav tsum tau muaj kev cuam tshuam tsawg kawg nkaus.

3. Lub sijhawm ROI ib txwm rau lub ntim ntim no yog dab tsi?

ROI lub sijhawm feem ntau yog nyob ntawm 16-24 lub hlis nyob ntawm qhov ntim ntau lawm thiab kev ntim khoom tam sim no. Cov koom haum tseem ceeb rau ROI suav nrog kev txo qis kev ua haujlwm (nruab nrab 68% txo), muaj peev xwm ntau lawm (nruab nrab 37% kev txhim kho), txo cov khoom pov tseg (nruab nrab 23% txo), thiab txhim kho pob zoo sib xws uas ua rau tsawg dua cov khw muag khoom tsis lees paub. Peb pab pawg neeg muag khoom tuaj yeem muab ROI tsom xam raws li koj qhov kev xav tau tshwj xeeb.

4. Yuav tsum muaj kev tiv thaiv dab tsi?

Lub kaw lus qhov kev kwv yees kev siv thev naus laus zis txo cov kev tu ib txwm siv los ntawm 35%. Yuav tsum muaj kev saib xyuas feem ntau suav nrog kev tshuaj xyuas lub puab tsaig txhua 250 teev ua haujlwm, ntsuas ntsuas ntsuas ntsuas ntsuas txhua hli, thiab ntsuas pneumatic lub hlis twg. Txhua qhov kev saib xyuas yuav tsum tau saib xyuas thiab teem sijhawm los ntawm HMI, uas muab cov txheej txheem tu ib ntus nrog cov lus qhia pom.

Yog lawm, yog nug, peb yuav muab cov ntsiab lus tseem ceeb ntsig txog Smart Weigh. Cov ntsiab lus tseem ceeb ntawm cov khoom, xws li lawv cov ntaub ntawv tseem ceeb, specs, cov ntaub ntawv, thiab cov haujlwm tseem ceeb, muaj nyob hauv peb lub vev xaib official.

Hauv Suav teb, lub sijhawm ua haujlwm zoo tib yam yog 40 teev rau cov neeg ua haujlwm puv sijhawm. Hauv Smart Weigh Ntim Machinery Co., Ltd., feem ntau cov neeg ua haujlwm ua haujlwm ua raws li txoj cai no. Thaum lub sijhawm lawv lub luag haujlwm, txhua tus ntawm lawv mob siab rau lawv txoj haujlwm tag nrho txhawm rau muab cov neeg siv khoom zoo tshaj plaws Packing Line thiab ib qho kev paub tsis nco qab ntawm kev koom tes nrog peb.

Cov neeg yuav khoom ntawm granule packing tshuab nqi los ntawm ntau lub lag luam thiab lub teb chaws thoob ntiaj teb. Ua ntej lawv pib ua haujlwm nrog cov neeg tsim khoom, qee tus ntawm lawv tuaj yeem nyob ntau txhiab mais deb ntawm Tuam Tshoj thiab tsis paub txog kev lag luam hauv Suav teb.

Hais txog tus cwj pwm thiab kev ua haujlwm ntawm lub tshuab granule packing nqi, nws yog ib yam khoom uas yuav ib txwm nyob hauv vogue thiab muab cov neeg siv khoom tsis muaj txiaj ntsig. Nws tuaj yeem ua phooj ywg ntev rau tib neeg vim tias nws yog tsim los ntawm cov khoom siv raw khoom zoo thiab muaj lub neej ntev.

Hais txog tus cwj pwm thiab kev ua haujlwm ntawm lub tshuab granule packing nqi, nws yog ib yam khoom uas yuav ib txwm nyob hauv vogue thiab muab cov neeg siv khoom tsis muaj txiaj ntsig. Nws tuaj yeem ua phooj ywg ntev rau tib neeg vim tias nws yog tsim los ntawm cov khoom siv raw khoom zoo thiab muaj lub neej ntev.

Smart Weigh Ntim Machinery Co., Ltd. ib txwm txiav txim siab sib txuas lus los ntawm kev hu xov tooj lossis kev sib tham hauv video uas txuag lub sij hawm tsis tau yooj yim, yog li peb zoo siab tos txais koj hu rau cov ncauj lus kom ntxaws chaw nyob. Los yog peb tau tso tawm peb qhov chaw nyob e-mail ntawm lub vev xaib, koj tuaj yeem sau E-mail rau peb txog lub Hoobkas chaw nyob.

Copyright © Guangdong Smartweigh Ntim Machinery Co., Ltd. | All Rights Reserved