Umatshini wethu wokupakisha wegranule ubonelela ngobuninzi bezinto ezizihambelayo ezizihambelayo eziphucula ukupakishwa kwe-cereal kunye nokuchaneka. Iimpawu eziphambili zibandakanya ukuphatha imveliso ethambileyo ukunciphisa ukwaphuka, ukupakishwa kwesantya esiphezulu, ulungelelwaniso oluzenzekelayo lobunzima bepakethe obuhambelanayo, kunye nolawulo lwesahlulo esinokwenziwa ngokwezifiso. Le nkqubo imele utyalo-mali olubalulekileyo kwitekhnoloji yokupakisha i-cereal, enikezela ngokusebenza okungenakulinganiswa kunye nemveliso kwixabiso elikhuphisanayo lomatshini wokupakisha igranule.

Kwinkampani yethu, sisebenza ngokukhethekileyo ekuboneleleni ngezisombululo ezizisebenzelayo zokupakisha iimveliso ezahlukeneyo, ngakumbi iisiriyeli. Umatshini wethu wokuPakisha iGranule uyilelwe ukupakisha ngokufanelekileyo nangokuchanekileyo iicereals kwiintlobo ezahlukeneyo zeebhegi. Ngobuchwephesha bokusika kunye nobunjineli obuchanekileyo, umatshini wethu uqinisekisa ukuhambelana kunye nomgangatho ophezulu kuyo yonke iphakheji. Siyazingca ngokuzisa izisombululo ezintsha ezilula ukusebenza kunye nokwandisa imveliso kubathengi bethu. Sithembe ukuba sinikezela ngezisombululo ezithembekileyo nezisebenzayo zokupakisha ezihlangabezana neemfuno zakho ezizodwa kwaye zigqithise ubulindele. Nathi, unokuqiniseka kumgangatho kunye nokusebenza kakuhle kweemveliso zethu.

Ngokuzibophelela okuqinileyo ekuveliseni izinto ezintsha kunye nokusebenza kakuhle, inkampani yethu igxile ekuboneleleni ngezisombululo ezizihambela phambili ze-automation kushishino lokupakisha. Umatshini wethu wokuPakisha iGranule uyilelwe ukulungelelanisa inkqubo yemveliso yokupakishwa kwee-cereal, enikezela ngokuchanekileyo kunye nesantya sokuhlangabezana neemfuno zezixhobo zanamhlanje zokuvelisa. Ngokugxila ekuthembekeni kunye nokusebenza komsebenzisi-friendly, umatshini wethu uxhotyiswe ngeteknoloji ye-cutting-edge ukuqinisekisa iziphumo zokupakisha ezihambelanayo kunye neziphezulu. Ukusuka kumashishini amancinci ukuya kwiinkampani ezinkulu, inkampani yethu iyazingca ngokuzisa izisombululo ezilungiselelwe ezonyusa imveliso kunye nenzuzo kubathengi bethu. Yiba namava kwikamva lokupakisha oluzenzekelayo ngomatshini wethu wokuPakisha iGranule.

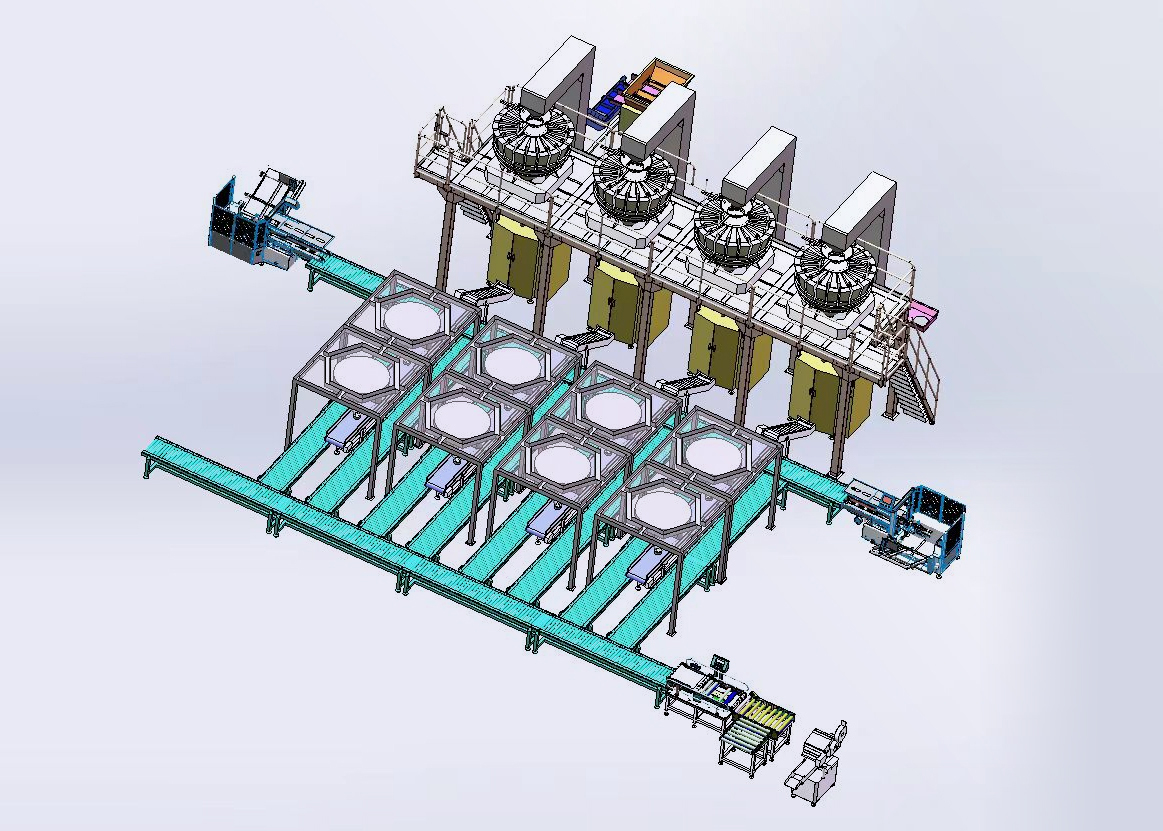

Phambili kwitekhnoloji yokupakisha okuziinkozo, inkqubo yethu yokupakisha ngokuzenzekelayo imele ukuqhubela phambili okubalulekileyo kwizisombululo zokupakisha eziqhelekileyo. Yenzelwe ngokukodwa ukutya okuziinkozo kwisidlo sakusasa, iigranola, kunye neemveliso zokutya ezomileyo ezifanayo, le nkqubo idibeneyo ifezekisa amanqanaba angazange abonwe ngaphambili okuzenzekelayo, inciphisa iimfuno zokungenelela kwabantu ukuya kuthi ga kwi-85% xa kuthelekiswa nezinye iindlela zokusebenza ngesandla.

Uyilo lwenkqubo lusebenzisa udibaniso oluphambili lwe-PLC kuwo onke amacandelo, idala ukuhamba kwemveliso engenamthungo ukusuka kwimveliso yokuqala yokutya ngokusebenzisa i-palletization. Itekhnoloji yethu yokulungelelanisa yobunini igcina unxibelelwano olufanelekileyo phakathi kwamacandelo, ukuphelisa i-micro-stops kunye nelahleko esebenzayo eqhelekileyo kwiinkqubo ezineendlela zokulawula ezihlukeneyo. Idatha yokuveliswa kwexesha langempela ihlalutywa ngokuqhubekayo yinkqubo yethu yokulawula i-adaptive, ukulungelelanisa ngokuzenzekelayo iiparitha ukugcina ukusebenza kakuhle nangona ukuhluka kweempawu zemveliso okanye iimeko zokusingqongileyo.

1. Inkqubo yokuhambisa ibhakethi

2. I-High-Precision Multihead Weigher

3. I-Ergonomic Support Platform

4. IFomu eNgqobileyo yokuGcwalisa umatshini wokutywina

5. ISikhululo sokuHlola soLawulo loMgangatho

6. I-High-Speed Output Conveyor

7. Automatic Boxing System

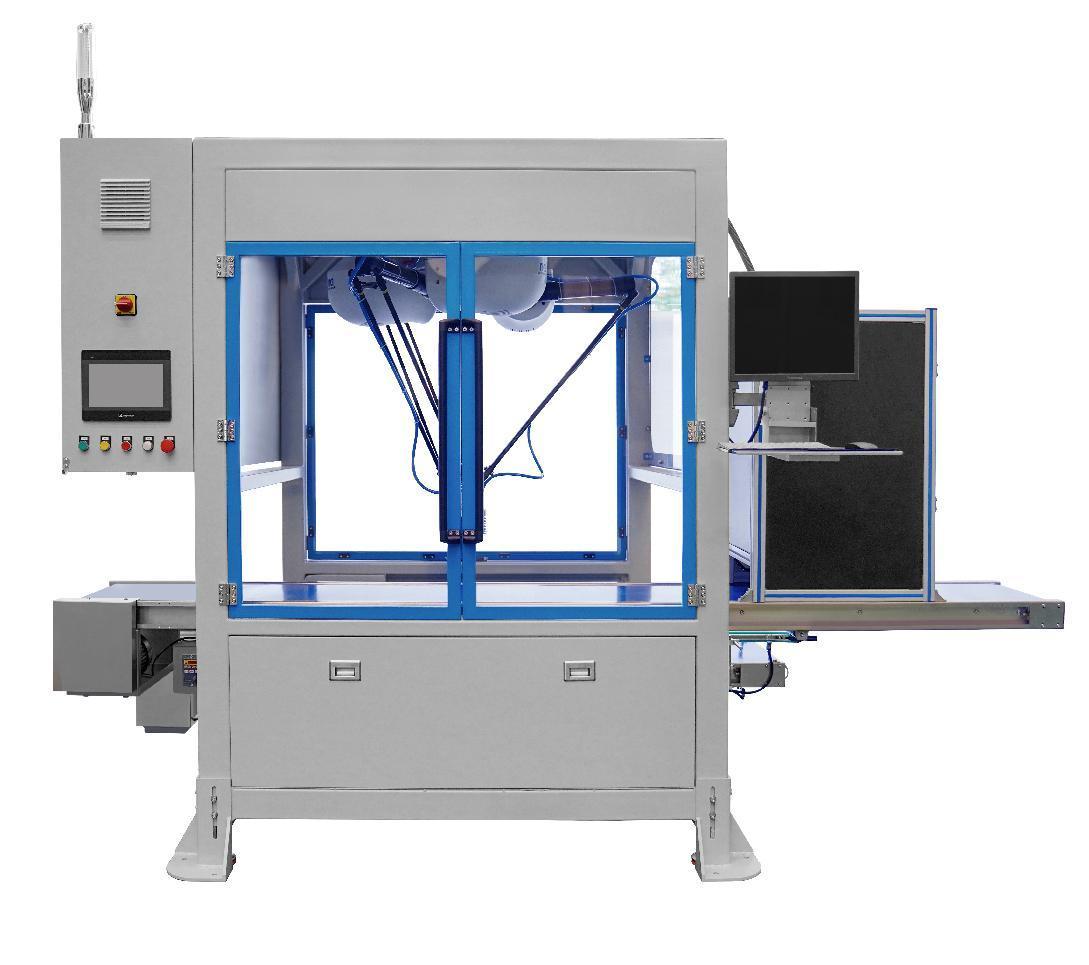

8. Delta Robot Pick-and-Place Unit

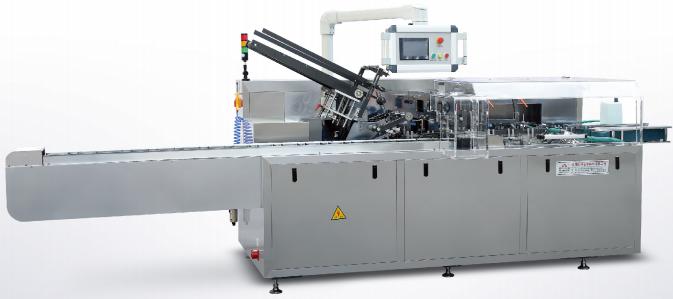

9. Umtshini weCartoning okrelekrele kunye neCarton Sealer

10. Inkqubo eDityanisiweyo yokuPalletizing

| Ubunzima | 100-2000 grams |

| Isantya | Iipakethi ze-30-180 / min (kuxhomekeke kwiimodeli zoomatshini), iimeko ze-5-8 / min |

| Isimbo seBag | Ibhegi yomqamelo, ibhegi yegusset |

| Ubungakanani bebhegi | Ubude 160-350mm, ububanzi 80-250mm |

| Izinto zefilimu | Ifilimu elayitiweyo, ifilimu eyodwa |

| Ukutyeba kwefilimu | 0.04-0.09 mm |

| Isohlwayo sokuLawula | 7" okanye 9.7 "Isikrini sokuchukumisa |

| Ukunikezwa Amandla | 220V/50Hz okanye 60Hz |

1. Inkqubo yokuhambisa ibhakethi

◆ Ukuphatha imveliso ethambileyo kunciphisa ukophuka kwamaqhekeza ecereal eethe-ethe

◆ Uyilo oluvaliweyo luthintela ungcoliseko kunye nokunciphisa uthuli

◆ Uthutho oluchanekileyo oluthe nkqo lwandisa ukusetyenziswa kwendawo emgangathweni

◆ Iimfuno zokugcinwa okuphantsi kunye nezakhono zokuzicoca

◆ Ukulawulwa kwesantya esilungelelanisiweyo ukuhambelana neemfuno zomgca wemveliso

2. I-High-Precision Multihead Weigher

◆ I-99.9% yokuchaneka iqinisekisa ubunzima bephakheji obuhambelanayo

◆ Imijikelo yokuweyisha ngokukhawuleza (ukuya kuthi ga kwi-120 ye-weights ngomzuzu)

◆ Ukulawulwa kwesahlulo esinokwenziwa ngokwezifiso kwiisayizi ezahlukeneyo zephakheji

◆ Ukulinganisa okuzenzekelayo kugcina ukuchaneka kuyo yonke imveliso

◆ Inkqubo yolawulo lweeresiphi ivumela ukutshintshwa kwemveliso ngokukhawuleza

3. I-Ergonomic Support Platform

◆ Iisetingi zobude obulungiswayo zinciphisa ukudinwa kwabaqhubi

◆ Iintsimbi zokhuseleko ezidityanisiweyo ziyahlangabezana nayo yonke imimiselo yokhuseleko kwindawo yokusebenza

◆ Uyilo lwe-Anti-vibration luqinisekisa uzinzo kunye nokusebenza ngokuchanekileyo

◆ Iindawo zofikelelo ekulondolozweni ngaphandle kwezixhobo zinciphisa ixesha lokuphumla

4. IFomu eNgqobileyo yokuGcwalisa umatshini wokutywina

◆ Ukupakishwa okuhamba ngesantya esiphezulu (ukuya kuthi ga kwiingxowa ezili-120 ngomzuzu)

◆ Iinketho ezininzi zesimbo sebhegi (umqamelo, ugutyungelwe)

◆ Ukutshintsha ngokukhawuleza imiqulu yefilimu kunye ne-auto-splicing

◆ Isakhono sokugungxulwa kwerhasi ixesha elide kwishelufu

◆ Ukuchaneka okuqhutywa yi-Servo kuqinisekisa izitywina ezigqibeleleyo rhoqo

5. ISikhululo sokuHlola soLawulo loMgangatho

◆ Izakhono zokubona isinyithi ukulungiselela ukhuseleko lokutya okuphezulu

◆ Ukuqinisekiswa kwe-Checkweigher kuphelisa iipakethe ezingaphantsi / ezigqithisileyo

◆ Indlela yokwala ngokuzenzekelayo kwiiphakheji ezingahambelaniyo

6. Ikhonkco leZiphumo zoThutho

◆ Ukutshintshwa kwemveliso egudileyo phakathi kwezigaba zokupakisha

◆ Ubuninzi bezakhono zokwahluka kwemveliso yesithinteli

◆ Uyilo lwemodyuli lulungelelanisa iimfuno zoyilo lwendawo

◆ Inkqubo yokulandelela ekwinqanaba eliphezulu igcina ukuqhelaniswa nephakheji

◆ Iindawo zokucoca ngokulula zihlangabezana nemigangatho yokhuseleko lokutya

7. Automatic Boxing System

◆ Iipateni zeemeko ezilungisekayo kwiimfuno ezahlukeneyo zokuthengisa

◆ I-erector yebhokisi edibeneyo kunye ne-adhesive e-hot-melt adhesive application

◆ Ukusebenza ngesantya esiphezulu (ukuya kuthi ga kwiziganeko ezingama-30 ngomzuzu)

◆ Ukutshintsha ngokukhawuleza isixhobo kwiisayizi ezininzi zeebhokisi

8. Delta Robot Pick-and-Place Unit

◆ Ukusebenza okukhawulezileyo (ukuya kuma-60 okukhethwa ngomzuzu kwiphakheji ye-500g)

◆ Ukuchaneka okukhokelwa ngumbono wokubekwa ngokugqibeleleyo

◆ Ukucwangciswa kwendlela yobuchule kunciphisa intshukumo yokusetyenziswa kwamandla

◆ Iprogram eguquguqukayo iphatha iindidi ezininzi zephakheji

◆ Umzobo obambeneyo wenza ukuba umgangatho womzi-mveliso ube mkhulu

9. Umtshini weCartoning okrelekrele

◆ Ukutya kunye nokwakheka kweebhokisi

◆ Ukuqinisekiswa kokufakwa kwemveliso kuphelisa iibhokisi ezingenanto

◆ Ukusebenza kwesantya esiphezulu kunye nexesha elincinci lokunciphisa

◆ Ubungakanani beebhokisi eziguquguqukayo ngaphandle kotshintsho olubanzi

10. Inkqubo eDityanisiweyo yokuPalletizing

◆ Iinketho ezininzi zeepalethi zepateni zozinzo olufanelekileyo

◆ I-automatic pallet dispensing and stretching of stretching

◆ Isicelo seleyibhile esidityanisiweyo sokulandelela izinto

◆ Isoftware yokuphucula ukulayisha yandisa ukusebenza kakuhle kokuthumela

◆ Ujongano lwenkqubo lwepateni olusebenziseka lula

1. Liliphi inqanaba lobuchwephesha obufunekayo ekusebenzeni le nkqubo yokupakisha?

Umsebenzisi omnye oneentsuku ze-3-5 zoqeqesho unokulawula ngokufanelekileyo yonke inkqubo ngokusebenzisa i-interface ye-HMI ephakathi. Inkqubo ibandakanya ukulawulwa kwesikrini esichukumisayo esinemigangatho emithathu yokufikelela: I-Operator (imisebenzi esisiseko), iSupervisor (uhlengahlengiso lweparameter), kunye neTechnician (ukugcinwa kunye nokuxilongwa). Inkxaso ekude iyafumaneka ukulungiselela ukulungisa ingxaki.

2. Ingaba le nkqubo iziphatha njani iintlobo ezahlukeneyo zeemveliso zeesiriyeli?

Inkqubo igcina ukuya kwiiresiphi zemveliso ezingama-200 kunye neeparitha ezithile zohlobo ngalunye lwecereal. Oku kubandakanya isantya sokutya esifanelekileyo, iipateni zokungcangcazela kwesikali se-multihead, ubushushu betywina kunye noxinzelelo loxinzelelo, kunye neeparitha zokuphatha ezingqale kwimveliso. Ukutshintshwa kweemveliso zenziwa nge-HMI kunye nohlengahlengiso oluzenzekelayo olufuna ukungenelela okuncinci.

3. Liliphi ixesha le-ROI eliqhelekileyo kule nkqubo yokupakisha?

Amaxesha e-ROI ngokuqhelekileyo aqala kwiinyanga ze-16-24 ngokuxhomekeke kumthamo wemveliso kunye nokusebenza ngokufanelekileyo kokupakisha. Abaxhasi abaphambili kwi-ROI babandakanya ukunciphisa abasebenzi (umyinge we-68% ukuncipha), ukunyuka kwamandla okuvelisa (umyinge we-37% yokuphucula), ukunciphisa inkunkuma (umyinge we-23% yokunciphisa), kunye nokuphuculwa kokuhambelana kwephakheji okubangelwa ukukhatywa kwentengiso okumbalwa. Iqela lethu lokuthengisa lobugcisa linokubonelela ngohlalutyo lwe-ROI olucwangcisiweyo olusekelwe kwiimfuno zakho ezithile zokuvelisa.

4. Loluphi ugcino lothintelo olufunekayo?

Itekhnoloji yogcino oluqikelelweyo lwenkqubo inciphisa ugcino olucwangcisiweyo lwemveli ngama-35%. Ulondolozo olufunekayo ikakhulu lubandakanya ukuhlolwa kwemihlathi yetywina rhoqo ngeeyure zokusebenza ezingama-250, uqinisekiso lokulinganisa isikali ngenyanga, kunye nokuhlolwa kwenkqubo yomoya rhoqo ngekota. Zonke iimfuno zokugcinwa zibekwe esweni kwaye zicwangciswe nge-HMI, ebonelela ngeenkqubo zokugcinwa kwamanyathelo ngamanyathelo kunye nezikhokelo ezibonakalayo.

Ewe, ukuba siceliwe, siya kubonelela ngeenkcukacha ezifanelekileyo zobugcisa malunga ne-Smart Weigh. Iinyaniso ezisisiseko malunga neemveliso, ezifana nemathiriyeli yazo yokuqala, iispekthi, iifom, kunye nemisebenzi ephambili, ziyafumaneka kwiwebhusayithi yethu esemthethweni.

E-China, ixesha eliqhelekileyo lokusebenza ziiyure ezingama-40 kubasebenzi abasebenza ngokusisigxina. Kwi-Smart Weigh Packaging Machinery Co., Ltd., uninzi lwabasebenzi lusebenza ngokuthobela olu hlobo lomgaqo. Ngexesha lomsebenzi wabo, ngamnye kubo unikela ingqalelo epheleleyo kumsebenzi wabo ukuze abonelele abathengi ngowona mgca wokuPakisha ukumgangatho ophezulu kunye namava angalibalekiyo okubambisana nathi.

Abathengi bexabiso lomatshini wokupakisha igranule baphuma kumashishini amaninzi nakwizizwe zehlabathi. Phambi kokuba baqale ukusebenza nabavelisi, abanye babo banokuhlala kumawaka eekhilomitha ukusuka eTshayina kwaye bengenalwazi ngentengiso yaseTshayina.

Ngokumalunga neempawu kunye nokusebenza kwexabiso lomatshini wokupakisha igranule, luhlobo lwemveliso eya kuhlala ikwimo kwaye inika abathengi inzuzo engenamda. Ingangumhlobo ohlala ixesha elide ebantwini kuba yakhiwe ngezinto ezikrwada ezikumgangatho ophezulu kwaye inobomi obude.

Ngokumalunga neempawu kunye nokusebenza kwexabiso lomatshini wokupakisha igranule, luhlobo lwemveliso eya kuhlala ikwimo kwaye inika abathengi inzuzo engenamda. Ingangumhlobo ohlala ixesha elide ebantwini kuba yakhiwe ngezinto ezikrwada ezikumgangatho ophezulu kwaye inobomi obude.

I-Smart Weigh Packaging Machinery Co., Ltd. ihlala ithathela ingqalelo ukunxibelelana ngeminxeba okanye ngencoko yevidiyo yeyona ndlela yonga ixesha kodwa iluncedo, ke siyakwamkela umnxeba wakho wokubuza idilesi yefektri eneenkcukacha. Okanye sibonise idilesi ye-imeyile kwiwebhusayithi, ukhululekile ukusibhalela i-imeyile malunga nedilesi yefektri.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | Onke Amalungelo Agciniwe