E entsoe ka ho khetheha bakeng sa lijo-thollo tsa hoseng, li-granola, le lihlahisoa tse tšoanang tsa lijo tse omeletseng, sistimi ena e kopaneng e fihlela maemo a ikhethileng a boits'oaro, a fokotsa litlhoko tsa ho kenella ha batho ka 85% ha e bapisoa le mekhoa e meng ea ts'ebetso ea matsoho.

ROMELA POTSO HONA

Ka pele ho theknoloji ea ho paka lijo-thollo, sistimi ea rona ea ho paka ka boiketsetso e emela tsoelo-pele e kholo holim'a litharollo tse tloaelehileng tsa ho paka. E entsoe ka ho khetheha bakeng sa lijo-thollo tsa hoseng, li-granola, le lihlahisoa tse tšoanang tsa lijo tse omeletseng, sistimi ena e kopaneng e fihlela maemo a ikhethileng a boits'oaro, a fokotsa litlhoko tsa ho kenella ha batho ka 85% ha e bapisoa le mekhoa e meng ea ts'ebetso ea matsoho.

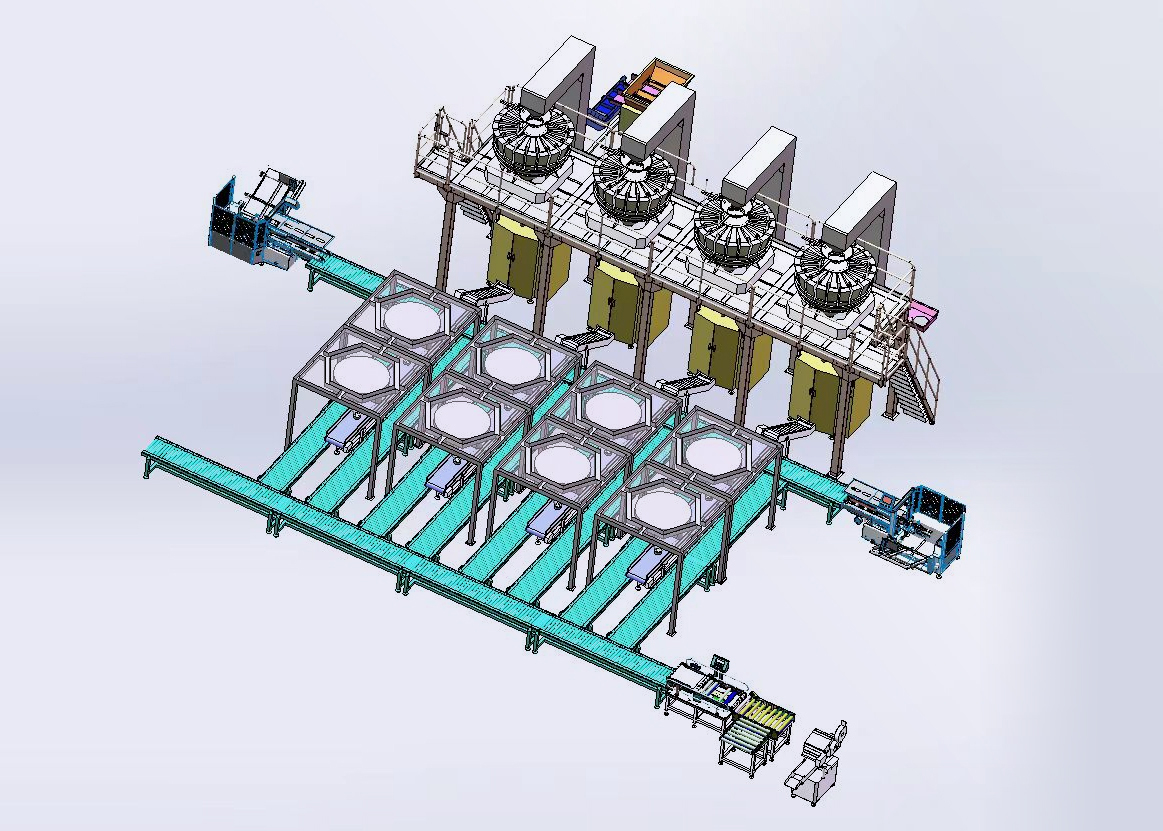

Meaho ea sistimi e sebelisa kopanyo e tsoetseng pele ea PLC ho likarolo tsohle, e theha phallo e se nang moeli ea tlhahiso ho tsoa ho phepelo ea sehlahisoa sa pele ka palletization. Theknoloji ea rona ea ho hokahanya ha thepa e boloka puisano e nepahetseng pakeng tsa likarolo, ho felisa li-micro-stops le tahlehelo ea katleho e tloaelehileng tsamaisong e nang le mekhoa e fapaneng ea taolo. Lintlha tsa tlhahiso ea nako ea 'nete li ntse li hlahlojoa ka mokhoa o tsoelang pele ke sistimi ea rona ea ho ikamahanya le maemo, e ikamahanyang le maemo ho boloka ts'ebetso e nepahetseng ho sa tsotellehe phapang ea litšobotsi tsa sehlahisoa kapa maemo a tikoloho.

1. Bakete Conveyor System

2. High-Precision Multihead Weigher

3. Sethala sa Tšehetso sa Ergonomic

4. Advanced Vertical Foromo Tlatsa Seal Machine

5. Seteishene sa Tlhahlobo ea Taolo ea Boleng

6. High-Speed Output Conveyor

7. Automatic Boxing System

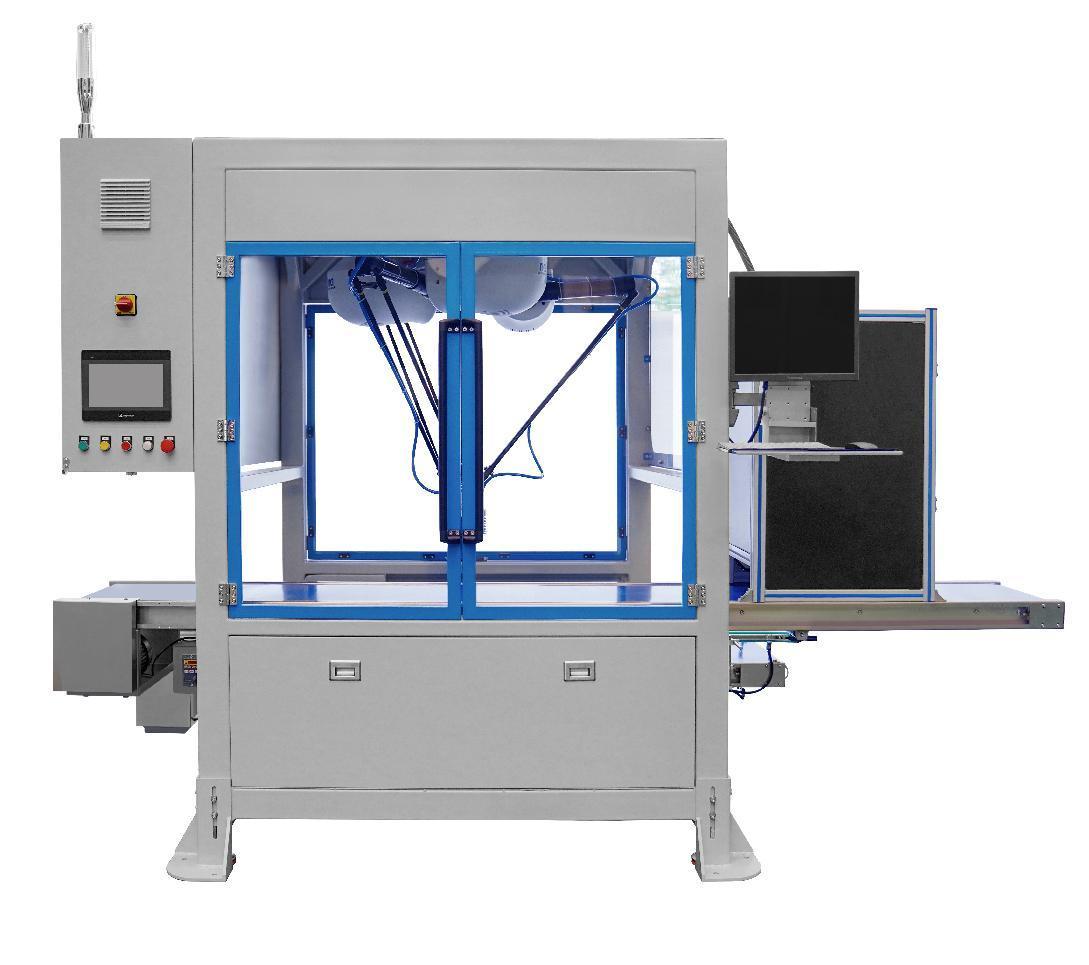

8. Sehlopha sa Delta Robot Khetha le Sebaka

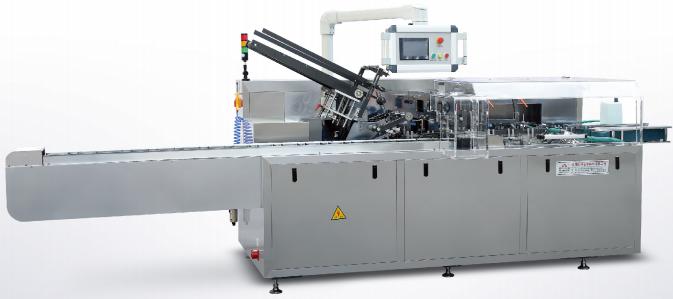

9. Mochini o Bohlale oa Cartoning le Carton Sealer

10. Mokhoa o kopantsoeng oa Palletizing

| Boima ba 'mele | 100-2000 dikgerama |

| Lebelo | Lipakete tsa 30-180 / min (ho itšetlehile ka mehlala ea mochine), linyeoe tsa 5-8 / min |

| Mokotla Style | Mokotla oa mosamo, mokotla oa gusset |

| Boholo ba Mokotla | Bolelele 160-350mm, bophara 80-250mm |

| Boitsebiso ba Filimi | Filimi e entsoeng ka laminated, filimi e le 'ngoe |

| Botenya ba lifilimi | 0.04-0.09 limilimithara |

| Control Penal | 7" kapa 9.7 "Touch Screen |

| Phepelo ea motlakase | 220V/50 Hz kapa 60Hz |

1. Bakete Conveyor System

◆ Ho sebetsana le sehlahisoa ka bonolo ho fokotsa ho robeha ha likotoana tsa lijo-thollo

◆ Moralo o kentsoeng o thibela tšilafalo le ho fokotsa lerōle

◆ Lipalangoang tse emeng tse otlolohileng hantle li eketsa tšebeliso ea sebaka sa fatše

◆ Litlhoko tse tlaase tsa tlhokomelo e nang le bokhoni ba ho itlhoekisa

◆ Taolo ea lebelo e feto-fetohang ho lumellana le litlhoko tsa mohala oa tlhahiso

2. High-Precision Multihead Weigher

◆ 99.9% ho nepahala ho tiisa boima ba sephutheloana bo lumellanang

◆ Lipotoloho tse potlakang tsa ho bekha (ho fihla ho li-weight tse 120 ka motsotso)

◆ Taolo ea karolo e ka khonehang bakeng sa boholo bo fapaneng ba liphutheloana

◆ Calibration e ikemetseng e boloka ho nepahala ho pholletsa le tlhahiso

◆ Sistimi ea taolo ea Recipe e lumella liphetoho tse potlakileng tsa sehlahisoa

3. Sethala sa Tšehetso sa Ergonomic

◆ Litlhophiso tsa bophahamo tse feto-fetohang li fokotsa mokhathala oa opareitara

◆ Litšepe tsa tšireletso tse kopantsoeng li kopana le melao eohle ea ts'ireletso ea sebaka sa mosebetsi

◆ Moralo oa anti-vibration o tiisa botsitso le ts'ebetso e nepahetseng

◆ Libaka tsa phihlello tsa tokiso ntle le lisebelisoa li fokotsa nako

4. Advanced Vertical Foromo Tlatsa Seal Machine

◆ Ho paka ka lebelo le phahameng (ho fihla ho mekotla e 120 ka motsotso)

◆ Likhetho tse ngata tsa mekotla (mosamo, o kentsoeng)

◆ Li-roll tsa lifilimi tse fetohang ka potlako tse nang le auto-splicing

◆ Bokhoni ba ho tsamaisa khase bakeng sa nako e telele ea sethala

◆ Ho nepahala ho tsamaisoang ke servo ho tiisa litiiso tse phethahetseng nako le nako

5. Seteishene sa Tlhahlobo ea Taolo ea Boleng

◆ Bokhoni ba ho lemoha ka tšepe bakeng sa polokeho ea lijo tse ngata

◆ Ho netefatsoa ha Checkweigher ho felisa liphutheloana tse tlase / boima bo feteletseng

◆ Mokhoa oa ho lahla o ikemetseng bakeng sa liphutheloana tse sa lumellaneng

6. Chain Output Conveyor

◆ Smooth sehlahisoa phetoho pakeng tsa ambalaji mekhahlelo

◆ Bokella bokhoni bo fapaneng buffer tlhahiso

◆ Moralo oa modular o ikamahanya le litlhoko tsa sebopeho sa setsi

◆ Mokhoa o tsoetseng pele oa ho latela mokhoa o boloka mekhoa ea liphutheloana

◆ Libaka tsa ho hloekisa habonolo li finyella litekanyetso tsa tšireletso ea lijo

7. Automatic Boxing System

◆ Mehlala ea linyeoe tse hlophisitsoeng bakeng sa litlhoko tse fapaneng tsa mabenkele

◆ Erector e kopantsoeng ea lebokose e nang le sekhomaretsi se chesang-melt

◆ Opereishene e potlakileng (ho fihla ho linyeoe tse 30 ka motsotso)

◆ Ho fetola ka potlako lisebelisoa bakeng sa boholo ba mabokose a mangata

8. Sehlopha sa Delta Robot Khetha le Sebaka

◆ Ts'ebetso e potlakileng haholo (ho fihla ho likhetho tse 60 ka motsotso bakeng sa sephutheloana sa 500g)

◆ Pono-tataiso e nepahetseng bakeng sa ho behoa ho phethahetseng

◆ Ho rera tsela e bohlale ho fokotsa motsamao bakeng sa ho sebetsa hantle ha matla

◆ Mananeo a feto-fetohang a sebetsana le mefuta e mengata ea liphutheloana

◆ Mehato e moqotetsane e ntlafatsa sebaka sa fektheri

9. Mochini o Bohlale oa Cartoning

◆ Ho fepa le ho theha mabokose a ikemetseng

◆ Ho netefatsa ho kenngoa ha lihlahisoa ho felisa mabokose a se nang letho

◆ Opereishene e potlakileng ka nako e fokolang

◆ Bongata bo feto-fetohang ba mabokose ntle le phetoho e pharaletseng

10. Mokhoa o kopantsoeng oa Palletizing

◆ Likhetho tse ngata tsa pallet bakeng sa botsitso bo nepahetseng

◆ Ho fana ka phallo e ikemetseng le ho phuthela ho otlolla

◆ Kopo e kopantsoeng ea label bakeng sa ho latedisa thepa

◆ Load optimization software e eketsa bokhoni ba ho tsamaisa thepa

◆ mosebedisi-ba botsoalle mohlala mananeo segokanyimmediamentsi sa sebolokigolo

1. Ke boemo bofe ba boitseanape bo hlokahalang ho sebelisa sistimi ee ea ho paka?

Motho ea sebetsang a le mong ea nang le matsatsi a 3-5 a koetliso a ka khona ho laola sistimi eohle ka sebopeho sa HMI se bohareng. Sistimi e kenyelletsa li-control tse hlakileng tsa "touchscreen" tse nang le maemo a mararo a phihlello: Opereishene (mesebetsi ea mantlha), Supervisor (liphetoho tsa paramethara), le Technician (tlhokomelo le tlhahlobo). Tšehetso ea Remote e teng bakeng sa ho rarolla mathata.

2. Tsamaiso e sebetsana joang le mefuta e fapaneng ea lihlahisoa tsa lijo-thollo?

Sistimi e boloka litlolo tse ka bang 200 tsa lihlahisoa tse nang le li-parameter tse ikhethileng bakeng sa mofuta o mong le o mong oa lijo-thollo. Tsena li kenyelletsa lebelo le nepahetseng la ho fepa, lipaterone tsa vibrate bakeng sa weigher ea li-multihead, mocheso oa tiiso le litlhophiso tsa khatello, le litekanyetso tse ikhethileng tsa ho sebetsana le sehlahisoa. Liphetoho tsa lihlahisoa li etsoa ka HMI ka liphetoho tse ikemetseng tse hlokang ho kenella ho fokolang ka letsoho.

3. Nako e tloaelehileng ea ROI bakeng sa tsamaiso ee ea ho paka ke efe?

Linako tsa ROI hangata li tloha likhoeling tsa 16-24 ho itšetlehile ka bophahamo ba tlhahiso le bokhoni ba hona joale ba ho paka. Bafani ba bohlokoa ho ROI ba kenyelletsa phokotso ea mosebetsi (karolelano ea 68% e fokotseha), matla a tlhahiso a eketseha (karolelano ea ntlafatso ea 37%), litšila tse fokotsehileng (karolelano ea 23% ea phokotso), le ho ntlafala ha sephutheloana ho fella ka ho hana mabenkele a fokolang. Sehlopha sa rona sa thekiso ea tekheniki se ka fana ka tlhahlobo e ikhethileng ea ROI ho latela litlhoko tsa hau tse khethehileng tsa tlhahiso.

4. Ke tlhokomelo efe ea thibelo e hlokahalang?

Theknoloji ea khale ea tlhokomelo ea tsamaiso e fokotsa tlhokomelo e hlophisitsoeng ea setso ka 35%. Tlhokomelo e hlokehang haholo-holo e kenyelletsa tlhahlobo ea mohlahare oa tiiso ka mor'a lihora tse ling le tse ling tse 250 tsa ts'ebetso, netefatso ea litekanyo tsa boima ba khoeli le khoeli, 'me sistimi ea moea e hlahlojoa ka kotara. Litlhoko tsohle tsa tlhokomelo li behiloe leihlo 'me li hlophisitsoe ka HMI, e fanang ka mehato ea mehato ea tlhokomelo ka litataiso tse bonahalang.

ITEANYE LE RONA

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Profinseng ea Guangdong, Chaena ,528425

Fumana Litlhaloso tsa Mahala Hona Joale!

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | Litokelo tsohle li sirelelitsoe