Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

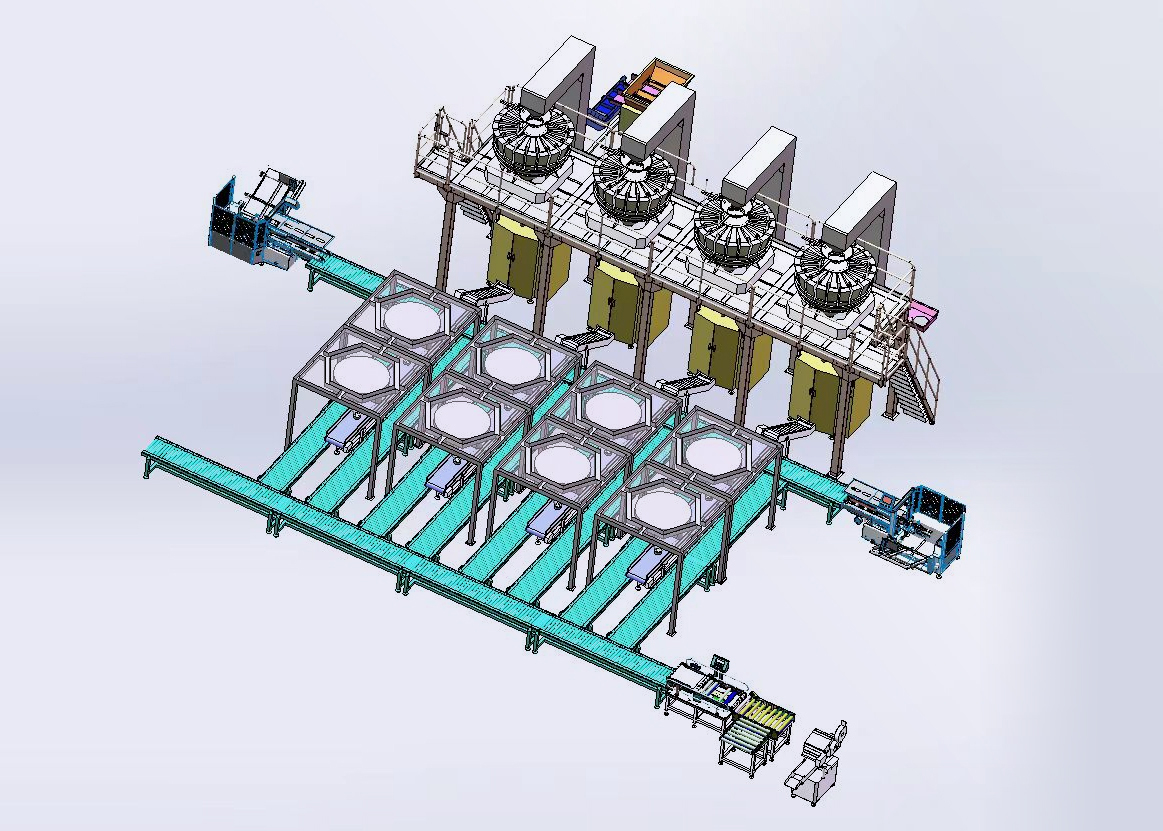

Engineered specifically for breakfast cereals, granolas, and similar dry food products, this integrated system achieves unprecedented levels of automation, reducing human intervention requirements by up to 85% compared to manual operation alternatives.

SEND INQUIRY NOW

At the forefront of cereal packaging technology, our fully automatic packaging system represents a significant advancement over conventional packaging solutions. Engineered specifically for breakfast cereals, granolas, and similar dry food products, this integrated system achieves unprecedented levels of automation, reducing human intervention requirements by up to 85% compared to manual operation alternatives.

The system architecture employs advanced PLC integration across all components, creating a seamless production flow from initial product feeding through palletization. Our proprietary synchronization technology maintains optimal communication between components, eliminating the micro-stops and efficiency losses common in systems with disparate control mechanisms. Real-time production data is continuously analyzed by our adaptive control system, automatically adjusting parameters to maintain optimal performance despite variations in product characteristics or environmental conditions.

1. Bucket Conveyor System

2. High-Precision Multihead Weigher

3. Ergonomic Support Platform

4. Advanced Vertical Form Fill Seal Machine

5. Quality Control Inspection Station

6. High-Speed Output Conveyor

7. Automatic Boxing System

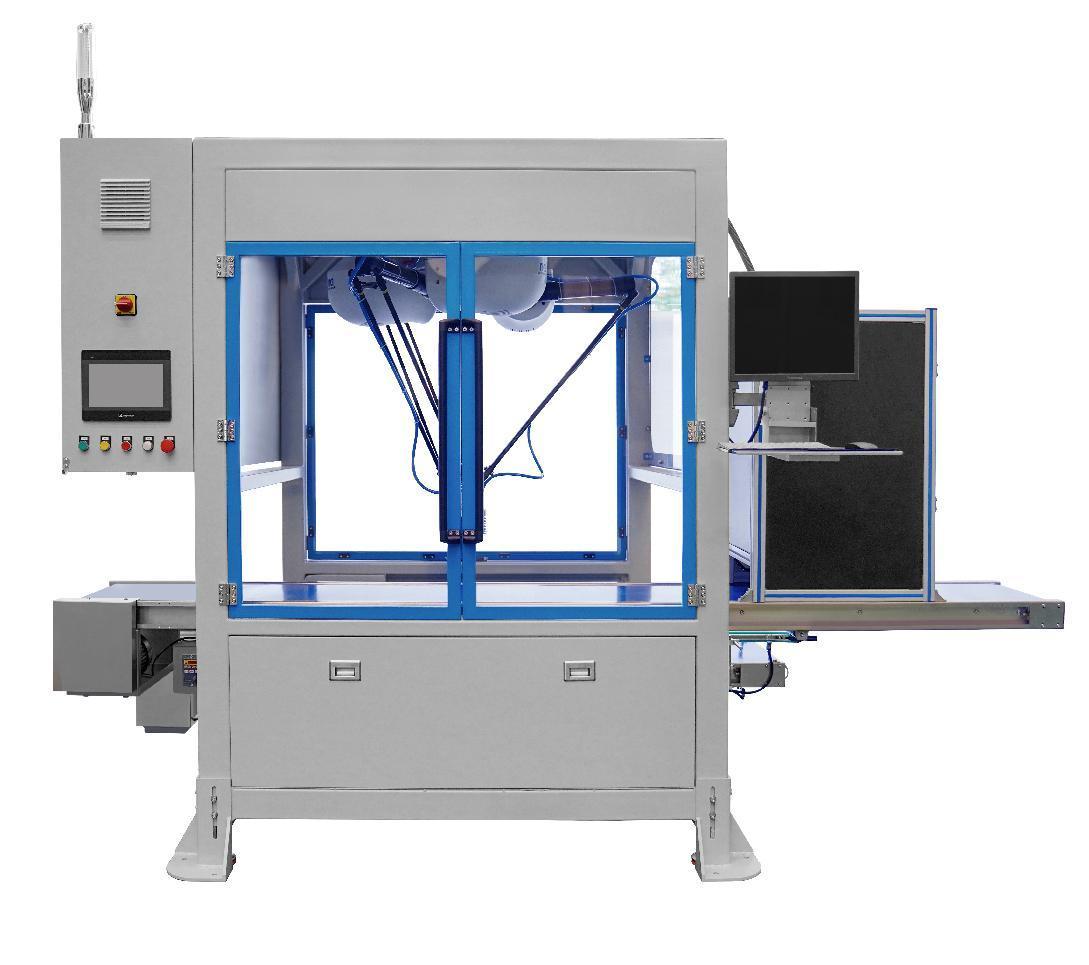

8. Delta Robot Pick-and-Place Unit

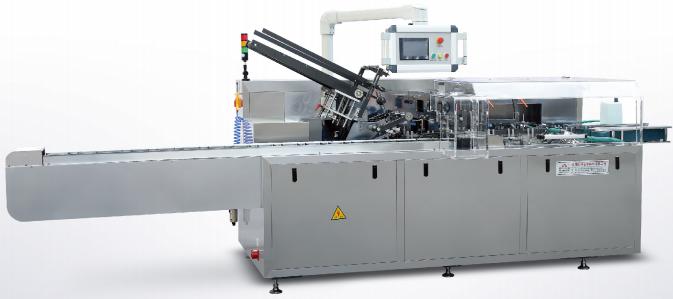

9. Intelligent Cartoning Machine and Carton Sealer

10. Integrated Palletizing System

| Weight | 100-2000 grams |

| Speed | 30-180 packs/min (depends on machine models), 5-8 cases/min |

| Bag Style | Pillow bag, gusset bag |

| Bag Size | Length 160-350mm, width 80-250mm |

| Film Material | Laminated film, single layer film |

| Film Thickness | 0.04-0.09 mm |

| Control Penal | 7" or 9.7 " Touch Screen |

| Power Supply | 220V/50 Hz or 60 Hz |

1. Bucket Conveyor System

◆ Gentle product handling minimizes breakage of delicate cereal pieces

◆ Enclosed design prevents contamination and reduces dust

◆ Efficient vertical transport maximizes floor space utilization

◆ Low maintenance requirements with self-cleaning capabilities

◆ Adjustable speed control to match production line requirements

2. High-Precision Multihead Weigher

◆ 99.9% accuracy guarantees consistent package weights

◆ Rapid weighing cycles (up to 120 weighments per minute)

◆ Customizable portion control for different package sizes

◆ Automatic calibration maintains precision throughout production

◆ Recipe management system allows quick product changeovers

3. Ergonomic Support Platform

◆ Adjustable height settings reduce operator fatigue

◆ Integrated safety railings meet all workplace safety regulations

◆ Anti-vibration design ensures stability and precise operation

◆ Tool-free maintenance access points minimize downtime

4. Advanced Vertical Form Fill Seal Machine

◆ High-speed packaging (up to 120 bags per minute)

◆ Multiple bag style options (pillow, gusseted)

◆ Quick-change film rolls with auto-splicing

◆ Gas-flush capability for extended shelf life

◆ Servo-driven precision ensures perfect seals every time

5. Quality Control Inspection Station

◆ Metal detection capabilities for maximum food safety

◆ Checkweigher validation eliminates under/overweight packages

◆ Automatic rejection mechanism for non-conforming packages

6. Chain Output Conveyor

◆ Smooth product transition between packaging stages

◆ Accumulation capabilities buffer production variations

◆ Modular design adapts to facility layout requirements

◆ Advanced tracking system maintains package orientation

◆ Easy cleaning surfaces meet food safety standards

7. Automatic Boxing System

◆ Configurable case patterns for different retail requirements

◆ Integrated box erector with hot-melt adhesive application

◆ High-speed operation (up to 30 cases per minute)

◆ Quick-change tooling for multiple box sizes

8. Delta Robot Pick-and-Place Unit

◆ Ultra-fast operation (up to 60 picks per minute for 500g package)

◆ Vision-guided precision for perfect placement

◆ Smart path planning minimizes movement for energy efficiency

◆ Flexible programming handles multiple package types

◆ Compact footprint optimizes factory floor space

9. Intelligent Cartoning Machine

◆ Automatic carton feeding and formation

◆ Product insertion verification eliminates empty cartons

◆ High-speed operation with minimal downtime

◆ Variable carton sizes without extensive changeover

10. Integrated Palletizing System

◆ Multiple pallet pattern options for optimal stability

◆ Automatic pallet dispensing and stretch wrapping

◆ Integrated label application for logistics tracking

◆ Load optimization software maximizes shipping efficiency

◆ User-friendly pattern programming interface

1. What level of technical expertise is required to operate this packaging system?

A single operator with 3-5 days of training can efficiently manage the entire system through the centralized HMI interface. The system includes intuitive touchscreen controls with three access levels: Operator (basic functions), Supervisor (parameter adjustments), and Technician (maintenance and diagnostics). Remote support is available for advanced troubleshooting.

2. How does the system handle different cereal product types?

The system stores up to 200 product recipes with specific parameters for each cereal type. These include optimal feeding speeds, vibration patterns for the multihead weigher, seal temperature and pressure settings, and product-specific handling parameters. Product changeovers are executed through the HMI with automated mechanical adjustments requiring minimal manual intervention.

3. What is the typical ROI period for this packaging system?

ROI periods typically range from 16-24 months depending on production volume and current packaging efficiency. Key contributors to ROI include labor reduction (average 68% decrease), increased production capacity (average 37% improvement), reduced waste (average 23% reduction), and improved package consistency resulting in fewer retail rejections. Our technical sales team can provide a customized ROI analysis based on your specific production requirements.

4. What preventative maintenance is required?

The system's predictive maintenance technology reduces traditional scheduled maintenance by 35%. Required maintenance primarily involves seal jaw inspection every 250 operating hours, weigher calibration verification monthly, and pneumatic system checks quarterly. All maintenance requirements are monitored and scheduled through the HMI, which provides step-by-step maintenance procedures with visual guides.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Get Free Quotation Now!

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved