Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Ready to eat meals are gaining immense hype these days because of their perfect combination of nutrients and deliciousness. Ready meals offer an escape from getting into the apron and delving into the process of making food, as all you have to do is to get them, microwave for a few minutes, and enjoy! No mess, no dirty dishes – all we want to save more time!

According to a recent study, around 86% of adults consume ready meals, with three out of ten consuming these meals once every week. If you count yourself among these stats, have you ever considered what packaging prevents ready meals from expiring? What sort of packaging retains its freshness? What technology and machinery is used in the process?

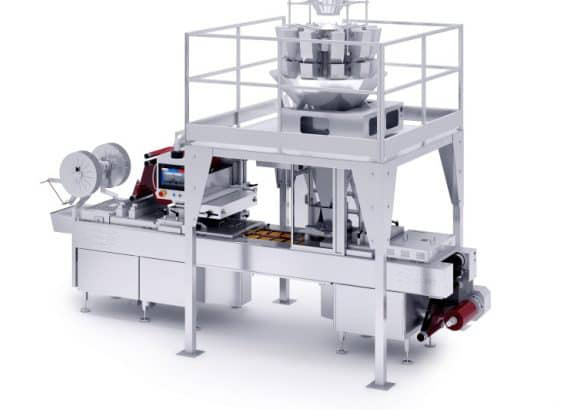

Ready meals packaging machines on the market all focus on the automatic packaging part, but Smart Weigh is different. We can automate the entire process, including automatic feeding, weighing, filling, sealing, coding, and more. We have covered you in this comprehensive guide if you are exploring the packaging and ready meal packaging machine. Let's dive in to begin exploring!

Where every industry embraces automation and digitalization, why not the ready meal packaging industry? That said, more and more packaging companies are revolutionizing their working strategies, introducing innovative ready meal vacuum packaging machines to reduce human touch and errors and save time and cost.

Following are the main technologies that ready to eat food packaging machines implement in their working:

Modified Atmosphere Packaging – Also known as reduced oxygen packaging, MAP involves filling the meal package with pure oxygen, carbon dioxide, and nitrogen. It doesn’t include any usage of chemical additives or preservatives that can be allergic to some people and might even affect food quality.

Vacuum Skin Packaging – Next, we have a VSP that relies on the VSP film technology to securely package the ready meals. It's all about creating a vacuum between the seal and the food to ensure the packaging remains tight and doesn't damage the container. Such packaging perfectly retains the freshness of food.

This machinery can be of several types, including:

· Feeding Machines: These machines deliver rte food products to weighing machines.

· Weighing Machines: These weigher weigh products as preset weight, they are flexible to weigh various food.

· Filling Mechanism: These machines fill up the ready meals into the one or multiple containers. Their automation level varies from semi-automatic to fully automatic.

· Ready Meal Sealing Machines: These can be either hot or cold sealers that create a vacuum inside the containers and seal them properly to prevent contamination.

· Labelling Machines: These are mainly responsible for labeling the packaged meals, mentioning the company name, ingredients' breakdown, nutrient facts, and all you expect a ready meal food label to reveal.

These ready to eat food packaging machine are the main packagers among all the other types because they are directly involved in sealing the food and preventing it from contamination. However, they can be of multiple types, depending on the technology they implement. Let's have a look at a few of the most common types!

1. Ready Meal Vacuum Packaging Machine

First on the list are the ready meal vacuum packaging machines. These machines mainly seal ready meals in flexible thermoforming film.

The packaging material used here must withstand both the temperature extremes, cold and hot. It's because once vacuum packed, packages are sterilized and stored in freezers, whereas once consumers have bought them, they cook the meals without removing the seals.

Features:

l Extends shelf life by reducing aerobic microbial growth.

l Different models available for small-scale and industrial applications.

l Some models include gas flushing capabilities for further preservation.

2. Ready Meal Thermoforming Packaging Machine

It works by heating a plastic sheet until it becomes pliable, then forming it into a specific shape using a mold, and finally cutting and sealing it to create a package.

The best part? With thermoforming packaging on, you can hang up your ready meals without worrying about the presentation or liquid flowing.

Features:

l Mold Customization, high level of customization in packaging shapes and sizes.

l Vacuum forming sucks the plastic sheet onto the mold, while pressure forming applies pressure from above, allowing for more detailed and textured packaging.

l Integration with filling systems for liquids, solids, and powders.

3. Ready Meal Tray Sealing Machine

These machines are destined for sealing ready meals contained in aluminum foil and plastic trays. Depending on the type of ready meal you are packaging, you can decide whether to seal only or implement vacuum or MAP sealing technologies.

Keep in mind that the sealing material here should be microwaveable so consumers can conveniently reheat meals before delving into them. Moreover, these machines also ensure high-temperature sterilization for better preservation of meals.

Features:

l Can handle various tray sizes and shapes.

l Capable of incorporating modified atmosphere packaging (MAP) to extend shelf life.

l Often equipped with temperature control for heat-sealing.

4. Ready Meals Retort Pouch Packaging Machine

Retort pouches are a type of flexible packaging that can withstand the high temperatures of retort (sterilization) processes. Rotary pouch packing machine is able to handle this type of pouch perfectly, pick, fill and seal. If needed, we also offer vacuum pouch packing machine for your choice.

Features:

l Versatility in handling different pouch styles.

l With 8 working station, capable of high-speed operations.

l Pouch sizes are adjustable on touch screen, quick changeover for new size.

5. Ready Meal Flow-Wrapping Machines

Lastly, we have flow-wrapping machines. In the former, products flow horizontally along the machine when wrapped into the film and sealed.

These packaging machines are mainly used for same-day selling of ready meals or instant noodles that don't require any sort of MAP or vacuum packaging for prolonged shelf-life.

The key to obtaining the right ready meal packaging system is a better understanding your business requirements. The following are the considerations that account for this regard:

· What type of ready meals do you want to pack?

Different machines are suited for different types of meals. For instance, vacuum packing is ideal for perishable items, while tray sealing might be better for meals like pasta or salads. And consider the types of packaging materials compatible with the machine, such as plastic, foil, or biodegradable materials, and ensure they align with your product needs and sustainability goals.

· What are the food components of the meal?

The most common collocation is the meat cubes + vegetables slices or cubes + noodles or rice, it is important to tell your supplier how many types of meat, vegetables and staple food will be packed, and how many combination here.

· How many capacity do you need to pack to meet your business demand?

The speed of the machine should match your production requirements. Consider the entire process, including filling, sealing, and labeling.High-volume production lines might benefit from fully automated systems, whereas smaller operations might require more flexible or semi-automated machines.

· How much space can you allot to your system?

Generally, fully automatic machines take up more space than semi-automatic ones. Informing your suppliers in advance if you have request for the space will allow them to better offer you a solution.

We recommend checking out our ready meal packaging system if you are looking for a premium meal packaging solution. At Smart Weigh, we believe in providing a complete set of automated packaging solutions for ready meals, breaking through limitations.Our packaging machines can be used in various combinations according to the nature of the packaging products to form a complete packaging machine line.

1. Provide a complete set of automated packaging solutions for ready meals, breaking through limitations and realizing automatic weighing and unloading functions.

2. Automatic weighing machine - combination scale multihead weigher, which can weigh various cooked meat, vegetables cubes or slices, rice and noodles

3. When the packaging machine is a Modified Atmosphere Packaging Machine, thermoforming packing machine or tray packing machine, the filling mechanism/filling machine exclusively developed by Smart Weigh can unload multiple trays at the same time to adapt to the speed of the packaging machine.

4. Smart Weigh is a ready meals packing machine manufacturer with rich experience, have finished more than 20 successful cases these 2 years.

Ready meal packing machine have indeed contributed to the betterment of ready meals and their retention over prolonged periods with increased shelf-life. With these machines, we can reduce the overall cost of the packaging and ensure optimal accuracy with minimal manpower involvement.

Thus reducing the chances of any human error that can lead to improper packaging and eventually spoiling food. Hope you found this info worth reading. Stay tuned for more of such informative guides!

If you are seeking the ready to eat food packaging machine, Smart Weigh is your best choice! Share us your details and request right now!

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved